Professional Sheet Metal Laser Cutting Services

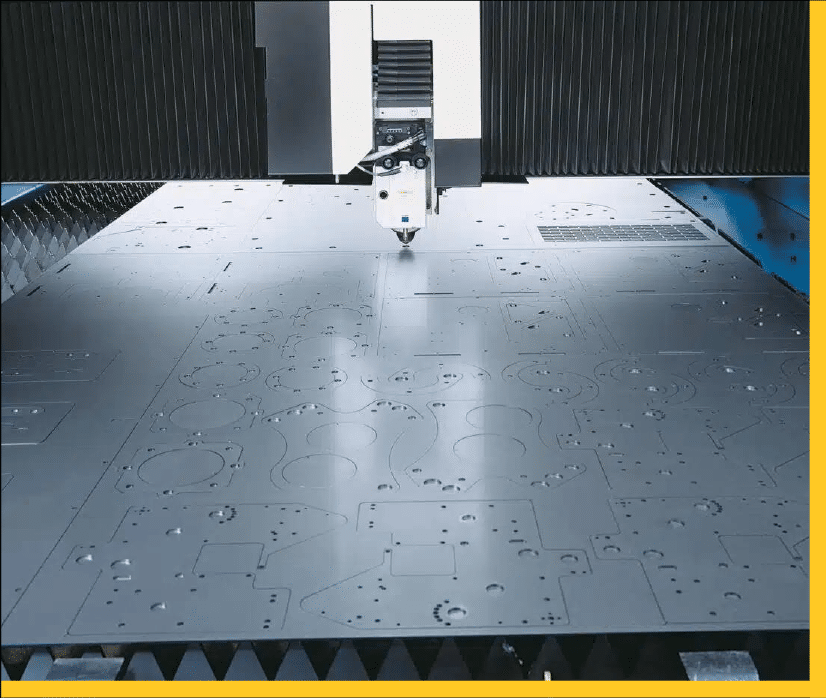

From our Sheffield-based facility, we offer rapid, high-capacity laser cutting with 24-hour lights-out manufacturing. Our in-house design team and full processing services ensure speed and quality from start to finish.

We operate two advanced flatbed lasers (up to 2000 x 4000mm and 50mm thick) alongside access to six more cutting-edge machines – including the UK’s first 15kW laser on a 6000 x 2500mm bed. Our 6kW and 10kW fibre lasers deliver clean cuts, reducing the need for pre-weld preparation.

Using CNC technology, we achieve precise, intricate cuts on a wide range of metals, with capabilities like chamfering and countersinking in a single process. Efficient nesting helps keep costs down and retain quality while maximising material use.

Key Benefits of Sheet Metal Laser Cutting

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices

Versatile and complex designs within rapid cutting speed

Up to 50mm thick

Highly accurate with a tolerance of +-0.25mm

ISO9001 and BS/EN 1090-1 accredited service

Up to 2.5m x 6m sheet metal

CE & UKCA compliant with traceable components

Nationwide delivery

Reliable service

Request a free no-obligation quote

Our Sheet Metal cutting services

- Sheet Laser Cutting

- Tube Laser Cutting

- Bevel & Countersink

- Flow Drilling & Tapping

- Metal Forming

- Smart Design Production

Why Laser Cutting Co.?

Experience

With 45+ years at the forefront of specialist cutting, we understand the nuances of each industry

Service

We make procurement easy with simple and transparent customer service and years of industry expertise. Your parts are our priority.

Quality

Operating to ISO 9001 and CE Marking BS/EN 1090-1 EXC4, we are proud to provide a second to none service.

Environmental Initiatives

Fully ISO-14001 accredited, we are committed to making your supply chain greener with solar energy

Capacity and Reliability

Operating 24/7 across all services, we guarantee short lead times for projects of all sizes

Our Quality Promise

The highest possible quality standards with the after sales support to match. Our Factory Production Controls are in accordance with legally enforceable construction product regulation BS EN 1090 – Level 3, allowing intricate cutting of construction regulation profiles. We are certified to BS EN ISO 9001:2015 for all profiling requirements.

Sheet Metal Laser Cutting FAQs

What is sheet metal laser cutting?

Sheet metal laser cutting is a precise and efficient industrial process that uses a high-powered laser beam to cut intricate shapes, designs, or patterns from flat sheets of metal. The laser beam heats and vaporises material, creating accurate cuts with minimal heat-affected zones.

What types of metals can be laser cut?

Laser cutting is an extremely versatile method of processing a wide range of sheet metals, some of which include:

- Stainless steel

- Mild/carbon steel

- Aluminium

- Titanium

- Brass

- Copper

- Bronze

- Alloys

The suitability of metal for laser cutting depends on factors like thickness, reflectivity, and thermal conductivity. For more information, contact The Laser Cutting Co. today.

How does sheet metal laser cutting work?

Laser cutting machines direct a focused laser beam onto the metal surface. The intense heat from the laser melts or vaporises the material along the designated cutting path. Simultaneously, a nitrous jet blows away the molten metal, resulting in a precise cut. CNC programming guides the laser’s movement to create intricate shapes.

What are the advantages of sheet metal laser cutting?

Sheet metal laser cutting offers high precision, intricate detailing, minimal material wastage, reduced tool wear, fast production times, and the ability to cut complex shapes without the need for specialised tooling.

What sheet thicknesses can be laser cut?

At The Laser Cutting Co., we can cut metal sheet thicknesses from 0.1mm up to 50mm thick, depending upon the sheet metal chosen.

For expert sheet metal laser cutting services, contact The Laser Cutting Co. today.

What industries commonly use sheet metal laser cutting?

Sheet metal laser cutting is utilised across an expansive range of industries, including automotive manufacturing, electronics, architecture, signage, medical device production, consumer goods manufacturing, and much more.

Can laser cutting be used for etchings and engravings on sheet metal?

Yes, laser cutting machines can be used for engraving and etching operations on sheet metal surfaces, allowing for detailed designs, serial codes, batch numbers, QR codes, and logos.

For bespoke laser etching and engraving services, contact The Laser Cutting Co. today.

What is the cost of sheet metal laser cutting?

The cost of sheet metal laser cutting depends on various factors including material type, thickness, complexity of the design, production volume, and machine time.

For a bespoke sheet metal laser cutting quote, get in touch with the experts at The Laser Cutting Co.