Flow Drilling In Sheffield

Laser Cutting Co provides professional Flow Drilling services in Sheffield for industries in a multitude of sectors, such as automotive and much more. Flow Drilling and Tapping form a key part of our TLCC Smart Design Production process where customers benefit from a reduction of up to 50% in production time and costs. Our innovative approach not only guarantees accuracy and reliability of parts, but allows customers to reap the rewards of a more efficient production line.

What Are The Benefits Of Flow Drilling?

Stronger fixing using existing material available.

Zero waste

Production time and costs incurred reduced by over 50%

Complete accuracy to a laser cutting tolerance of +-0.25mm

No risk of alternative fixings spinning or breaking, both at tapping stage or completed part/product.

What Is Flow Drilling?

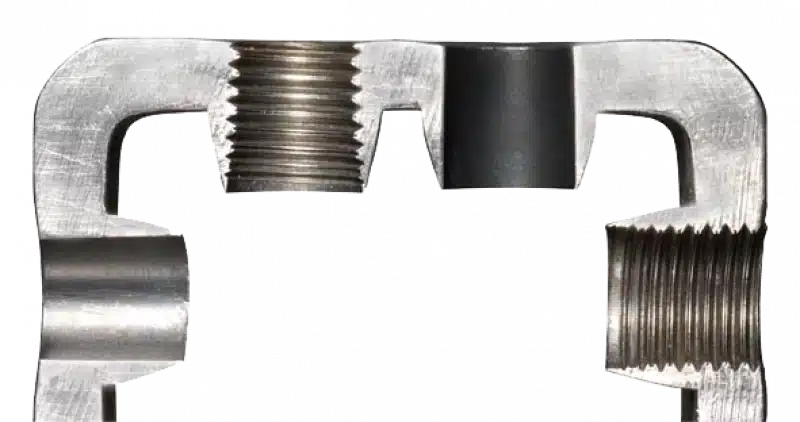

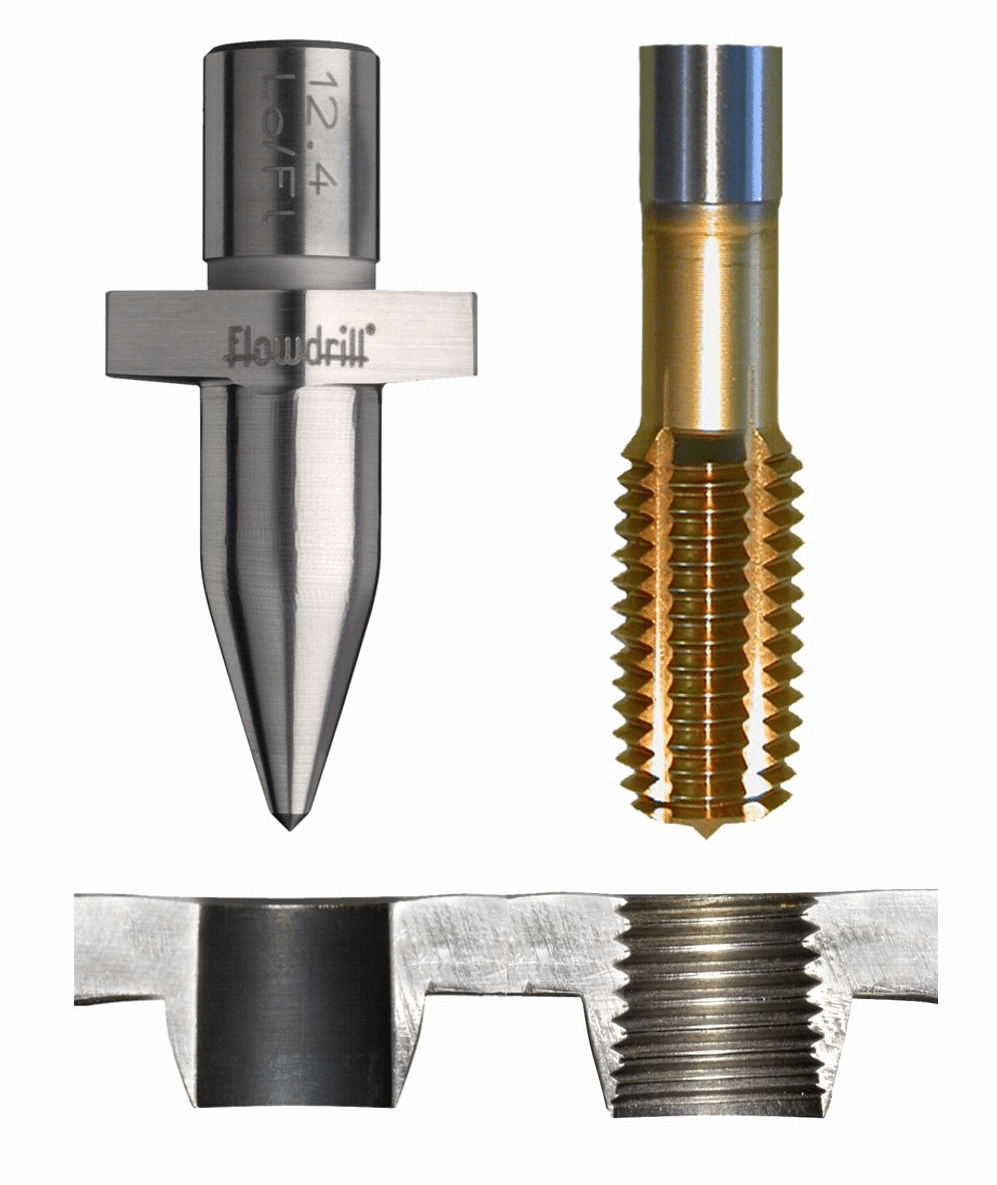

Flow Drilling is a strong and cost-efficient alternative to traditional fastening methods, such as weld nuts or nut-serts. It involves a FlowDrill, which is slowly pressed into the material as it rotates at high speed. This creates friction and heat that causes the material to “flow” and create a strong and uniform fixing, increasing the surface area that can be tapped with no weak points.

How Flow Drilling Works

Flow Drilling provides an innovative, more reliable and cost-efficient connection alternative to traditional fastening methods such as weld nuts or nut-serts.

Existing material is used to create a strong and uniform fixing, increasing the surface area that can be tapped with no weak points.

Sizes range from M2 to M30 inc BSP sizes in material thicknesses from 0.5mm to 10mm with different material applications:

- Mild Steel

- Stainless Steel

- Copper

- Brass

- Bronze

- Aluminium

Our Flow Drilling Services

At Laser Cutting Co, we can work with a wide range of materials, including aluminum, steel, and titanium, and can handle various sizes and complexity for our Flow Drilling projects.

Flow Drilling and Tapping form a key part of our TLCC Smart Design Production process where customers benefit from a reduction in up to 50% reductions in production time and costs. Our innovative approach not only guarantees accuracy and reliability of parts, but allows customers to reap the rewards of a more efficient production line.

What Materials Can Be Flow Drilled?

Sizes range from M2 to M30 inc BSP sizes in material thicknesses from 0.5mm to 10mm with different material applications:

- The following materials can all be used to FlowDrill:

- Mild Steel

- Stainless Steel

- Copper

- Brass

- Bronze

Flow Drilling and Tapping FAQ's

What is flow drilling and tapping?

Flow drilling and tapping is an innovative and cost-efficient alternative to traditional fastening methods, such as weld nuts or nut-serts. It involves using a Flow Drill, which is slowly pressed into the material as it rotates at high speed. This process creates friction and heat, causing the material to “flow” and create a strong and uniform fixing, ultimately increasing the surface area that can be tapped without weak points.

How does flow drilling work?

Flow drilling works by utilising a Flow Drill that is pressed into the material while rotating at high speed. The friction and heat generated during this process cause the material to deform and create a strong, uniform fixing. This method increases the surface area available for tapping without introducing weak points

How does tapping work?

Tapping works by using a specialised tool called a tap, which is inserted into a pre-drilled hole. As the tap is rotated, it cuts and forms threads inside the hole. This process creates internal threads that match the specifications of the tap, allowing for the secure insertion of screws, bolts, or other threaded fasteners into the material.

What are the benefits of flow drilling and tapping?

The benefits of The Laser Cutting Co.’s flow drilling and tapping services include:

- Stronger fixing using existing material available.

- Zero waste production.

- Reduction of over 50% in production time and costs.

- Complete accuracy with a tolerance of +-0.25mm.

- No risk of alternative fixings spinning or breaking, both during the tapping stage or with the completed part/product.

What materials can be flow drilled and tapped?

Flow drilling and tapping can be applied to a variety of materials, including:

- Mild Steel

- Stainless Steel

- Copper

- Brass

- Bronze

- Aluminium

What sizes can be achieved with flow drilling and tapping?

At The Laser Cutting Co., sizes range from M2 to M30, including BSP sizes, in material thicknesses from 0.5mm to 10mm. This flexibility allows for a wide range of applications across different industries.

For more information regarding our flow drilling and tapping services, contact The Laser Cutting Co. today.

How does flow drilling contribute to efficient production?

Flow drilling and tapping form a key part of The Laser Cutting Co.’s Smart Design Production. This innovative approach not only guarantees accuracy and reliability of parts but also allows customers to benefit from up to 50% reductions in production time and costs, resulting in a more efficient production line.

What is the difference between flow drilling and tapping?

Flow drilling creates threads by pressing a rotating tool into the material, utilising heat and friction, while tapping involves cutting threads with a threaded tool inserted into a pre-drilled hole.

Can flow drilling and tapping be used together?

Yes, they often work in conjunction. Drilling precedes tapping when creating holes for threaded connections.

For a free quote, get in touch with our team at The Laser Cutting Co. today.