Laser Engraving and Etching In Sheffield

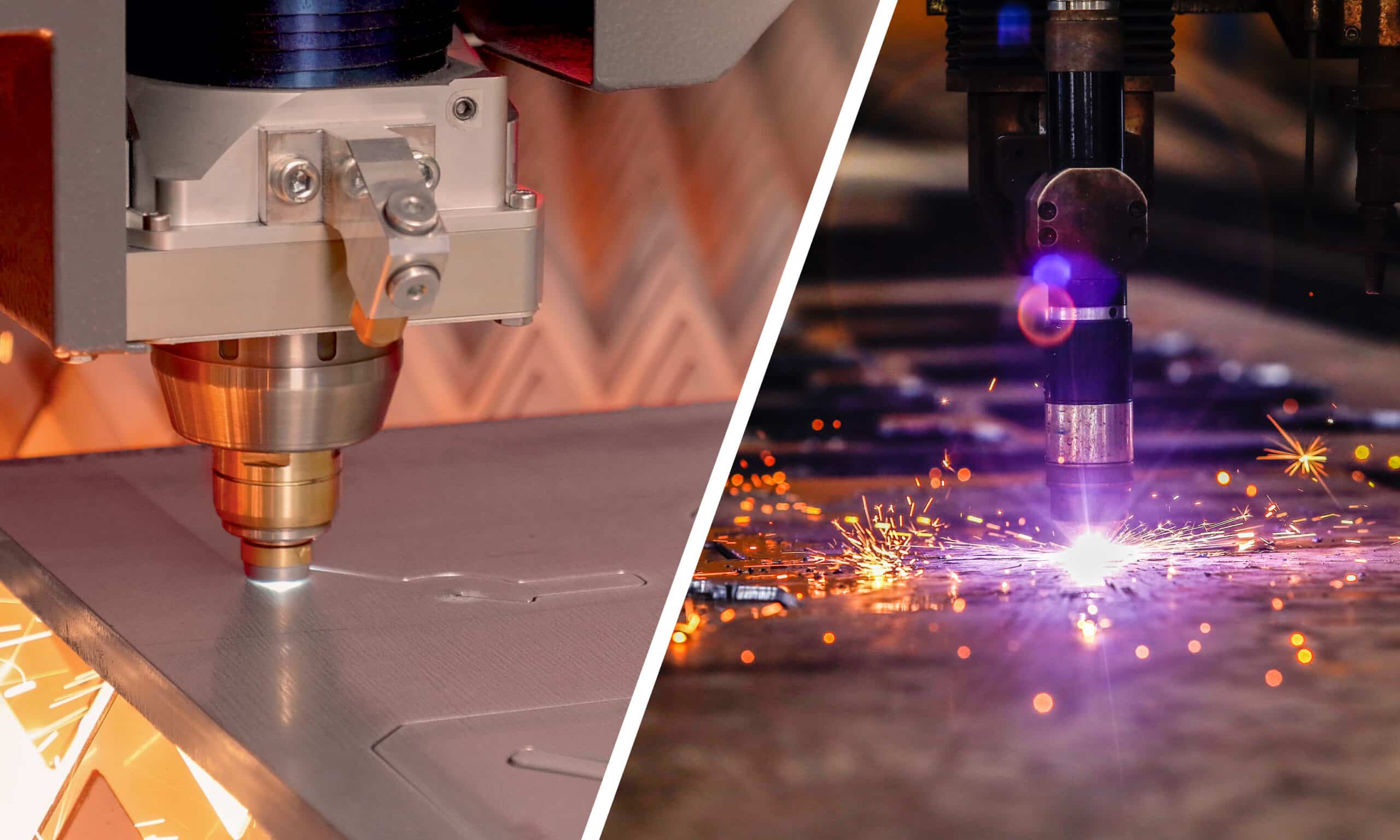

In the realm of modern manufacturing and design, laser cutting has revolutionised the way materials are processed and customised. At The Laser Cutting Co., we provide laser engraving and laser etching for a series of applications and industries, including the automotive, electronics, and industrial sectors.

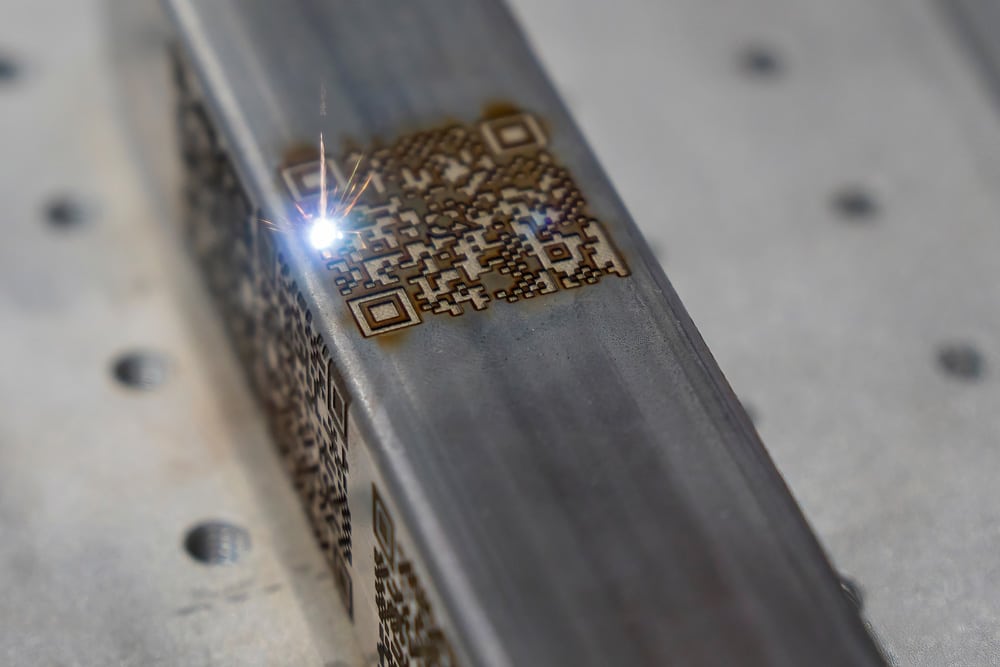

Most commonly used to apply serial codes, batch numbers, QR codes, and downstream maintenance data, laser engraving and etching are essential to supply chain traceability. Laser marking can also be employed for aesthetic purposes, commonly used to apply logos or complex decorative features to a range of materials including stainless steel, aluminium, acrylic and wood; no matter your engraving and etching needs, The Laser Cutting Co. has the expertise, experience, and capabilities to provide an exceptional service every time.

What is The Difference Between Laser Engraving and Laser Etching?

Laser engraving and laser etching are both laser-based processes used for marking and creating designs on various materials, but they differ in how they interact with the material and the type of marks they produce.

Laser Etching

Laser etching, on the other hand, is a process that doesn’t remove material from the surface but alters its appearance by causing a colour change or creating a visible contrast. The laser interacts with the material, modifying its surface properties without significant penetration or depth. This process is particularly effective on materials like metals, anodised aluminium, and some plastics. The marks produced through laser etching are generally flat and may not be tactile, as there is minimal material removal involved.

Laser Engraving

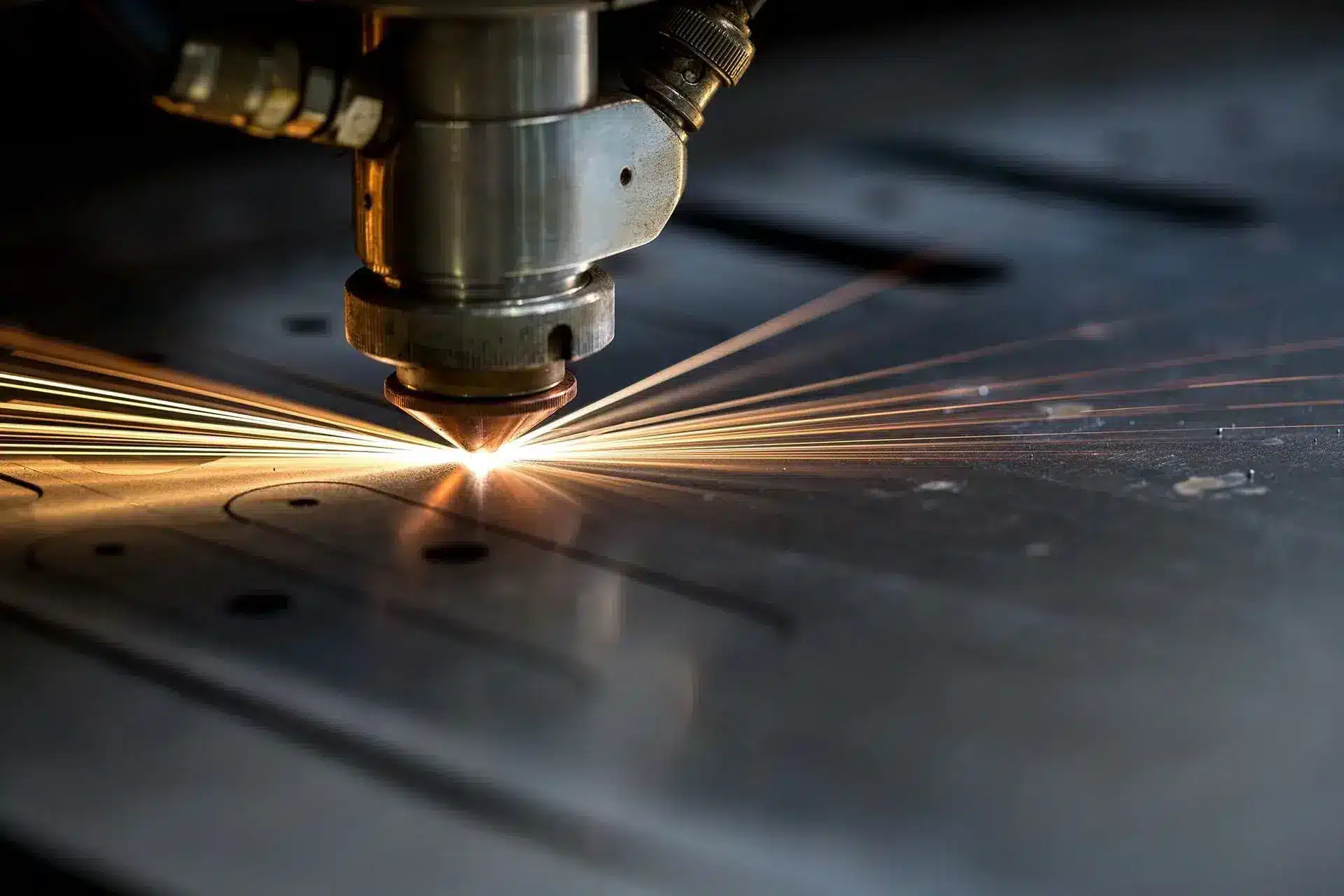

Laser engraving is a process where the laser beam removes material from the surface of the material being marked. The laser’s intensity is high enough to vaporise the material, leaving behind a cavity or indentation. This creates a noticeable depth in the engraved area, resulting in a tactile mark that can be felt when touched. The depth and contrast of the engraving depend on the power and speed settings of the laser, allowing for precise control over the final result. Laser engraving is commonly used for creating text, logos, and detailed designs on a variety of materials.

What Are The Benefits of Laser Engraving and Etching?

Laser engraving and etching are renowned for their unparalleled precision and intricate detailing. The use of a focused laser allows for the creation of highly accurate and detailed designs, logos, text, or graphics on a wide range of materials; with the correct source and settings, a laser can even engrave to the automotive industry’s required depth to mark VIN. This level of precision enables the reproduction of complex designs with flawless consistency, enhancing the overall aesthetics and value of your products.

One of the greatest advantages of laser engraving and etching is their versatility in working with various materials. Whether you require laser marking on hard metals, engraving on delicate materials, or etching on textured surfaces, our laser technology can handle it all. This adaptability makes it an ideal choice for a wide array of industries, including automotive, electronics, signage, and promotional products.

In today’s competitive market, personalisation has become a crucial aspect of product offerings. Laser engraving and etching provide a powerful means of customising items to cater to individual preferences and demands. From corporate merchandise to unique serial numbers on industrial parts, laser technology enables effortless customisation, fostering stronger customer loyalty and increased brand recognition.

Laser engraving and etching are highly efficient processes that significantly reduce production times compared to traditional methods. The automation and speed of laser cutting ensure quicker turnaround times, translating into cost savings for clients. Additionally, with minimal tool wear and no physical contact between the laser and the material, there is less waste, making these processes environmentally friendly and cost-effective

Through the use of contact-free laser marking technology, the need for direct physical contact with the material being processed is eliminated; therefore minimising the risk of damage, distortion, or contamination of the materials, especially in delicate applications. Moreover, this method is generally non-toxic, as no chemicals or inks are involved, ensuring the end product’s eco-friendliness.

The Laser Cutting Co.’s state-of-the-art laser cutting technology ensures remarkable consistency in each batch of engraved or etched items. Once a design or pattern is programmed, our laser cutters can reproduce it precisely across multiple pieces, ensuring uniformity in the final products. This level of consistency is particularly crucial for businesses that require large-scale production of branded items or identical components.

Laser engraving and etching seamlessly integrate with computer-aided design (CAD) software, enabling a smooth transition from digital designs to physical outputs. This digital compatibility allows for easier design modifications, quicker prototyping, and efficient batch processing, enabling rapid iterations and improvements without sacrificing quality.

Why Choose The Laser Cutting Co. for Laser Engraving and Etching Services?

The choice between laser engraving and laser etching depends on the material, the desired effect, and the specific application or requirements of the project. Our team of professional laser cutting experts will recommend the most suitable course of action to ensure the results of your project are to your exact requirements.

Our team of professional laser cutting experts understand that each project comes along with its own unique requirements and challenges; by entrusting us with your etching or engraving project, we guarantee to not only meet your expectations but exceed them.

For expertly-informed laser engraving and etching services, contact our team of professionals today.

Laser engraving and etching FAQs

What is the difference between laser engraving and laser etching?

Laser engraving involves removing material from the surface of an item to create a cavity that reveals an image or text at eye level, producing a tactile effect. Laser etching, on the other hand, modifies the surface of the material to create a design without removing material, typically resulting in a color change or contrast within the material itself.

What materials can be laser engraved or etched?

A wide variety of materials can be laser engraved or etched, including metals (such as stainless steel and aluminum), plastics, acrylics, wood, glass. The versatility of laser technology allows it to adapt to different material types and thicknesses.

How long does laser engraving or etching take?

The time required for laser engraving or etching depends on the complexity of the design, the type of material, and the size of the project. Simple designs on small objects may take only a few minutes, while more intricate or larger projects can take longer. The Laser Cutting Co. can provide specific time estimates based on project details. For more information, get in touch with our team of professionals today.

Is laser engraving and etching permanent?

Yes, both laser engraving and etching produce permanent marks that are resistant to fading, wear, and tear under normal conditions. This permanence makes them ideal for serial codes, QR codes, logos, and other markings meant to last the lifetime of the item.

How do I prepare a design for laser engraving or etching?

Designs should be provided in a vector graphic format (such as AI, SVG, or DXF) for the highest quality output. These formats allow for precise control over the engraving or etching process. If you’re unsure about your design file, The Laser Cutting Co. can offer assistance in preparing your design for optimal results.

How do I choose between laser engraving and etching for my project?

The choice between engraving and etching will depend on the material of your item, the desired visual effect, and the application of the finished product. Engraving may be preferred for a more tactile feel, while etching might be chosen for a more subtle design. The Laser Cutting Co. experts can recommend the best option based on your specific needs.

What are the benefits of choosing The Laser Cutting Co. for laser engraving or etching?

The Laser Cutting Co. offers state-of-the-art technology, precision, and detail in laser engraving and etching, capable of accommodating a wide range of materials and designs. With benefits like high efficiency, cost-effectiveness, and nationwide delivery, we ensure high-quality results tailored to your specific requirements.

How can I get a quote for my laser engraving or etching project?

To get a quote for your project, contact our team at The Laser Cutting Co. directly with details about your engraving or etching needs, including material type, size, and design specifications. We will provide you with a detailed quote based on the complexity and requirements of your project.