For precision manufacturing, kerf cutting is a fundamental concept that greatly influences the quality and accuracy of laser cutting services. With over four decades of direct industry experience and expertise, we here at The Laser Cutting Co. pride ourselves on our ability to deliver exceptional kerf cutting results, ensuring our customers receive the highest quality products with unmatched efficiency.

What is Kerf Cutting?

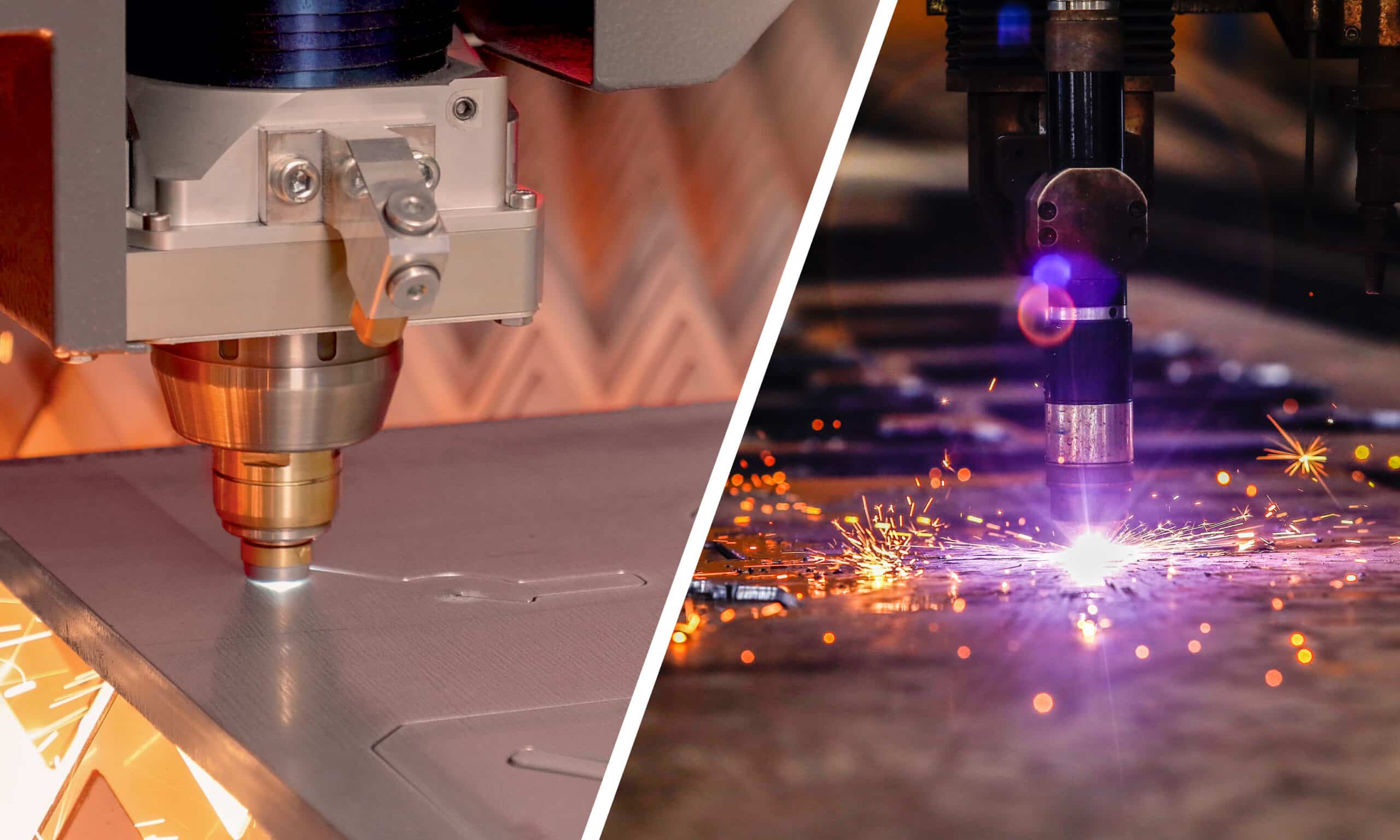

Kerf refers to the width of material that is removed by the cutting process. In laser cutting, the kerf is the gap created by the laser beam as it cuts through the material. Understanding and controlling the kerf width is essential for achieving precise cuts, especially in intricate designs and complex assemblies.

Why is Kerf Cutting Important?

The importance of kerf cutting lies in its impact on the final dimensions and fit of the cut parts. A well-controlled kerf ensures minimal material waste and high precision, which is crucial for industries where accuracy is paramount.

Whether it’s for aerospace, automotive, or medical device manufacturing, the precision of kerf cutting can make a significant difference in the performance and reliability of the final product.

Our Approach to Kerf Laser Cutting

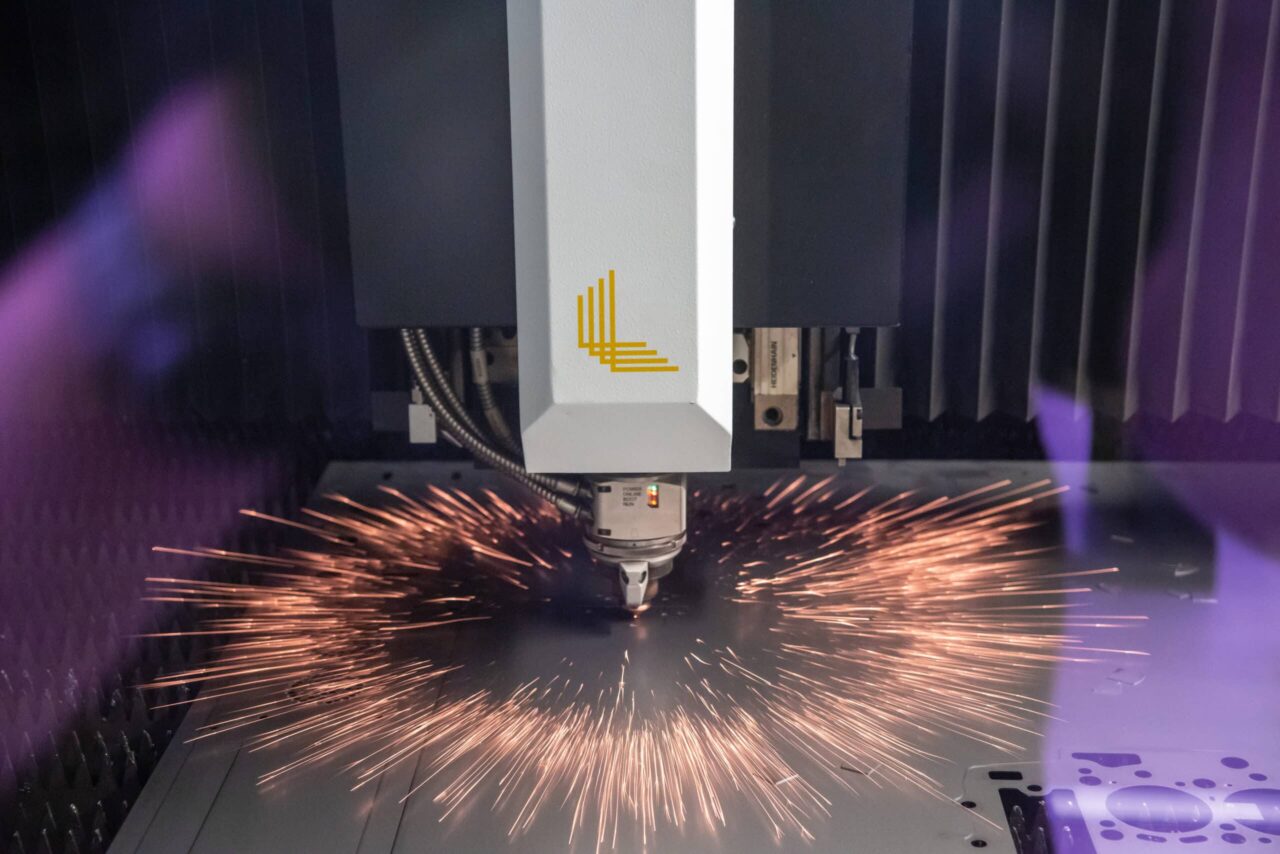

At The Laser Cutting Co., we leverage state-of-the-art laser cutting technologies to achieve optimal kerf cutting results. Our CNC fibre laser cutting machines operate 24 hours a day, providing rapid lead times and competitive prices. Committed to providing only the very best comprehensive metal profiling solutions, we continuously invest in the latest technologies to benefit our customers.

With our advanced laser cutting capabilities and Smart Design Production, we can reduce component volume, material waste, and overall complexity. Our precision cutting techniques accommodate a variety of materials and thicknesses, ensuring consistent quality across all projects. We can handle ferrous and non-ferrous metals, as well as film-coated surfaces, with sheet sizes up to 6000 x 2500mm and thicknesses up to 50mm.

Benefits of Our Kerf Cutting Services

Accuracy and Precision

Our laser cutting machines achieve an accuracy of +/- 0.25mm, ensuring that parts fit perfectly with minimal need for additional processing.

Efficiency

By optimising the kerf width, we reduce material waste and improve the overall efficiency of the cutting process. This translates to cost savings for our customers and a more sustainable approach to manufacturing.

Versatility

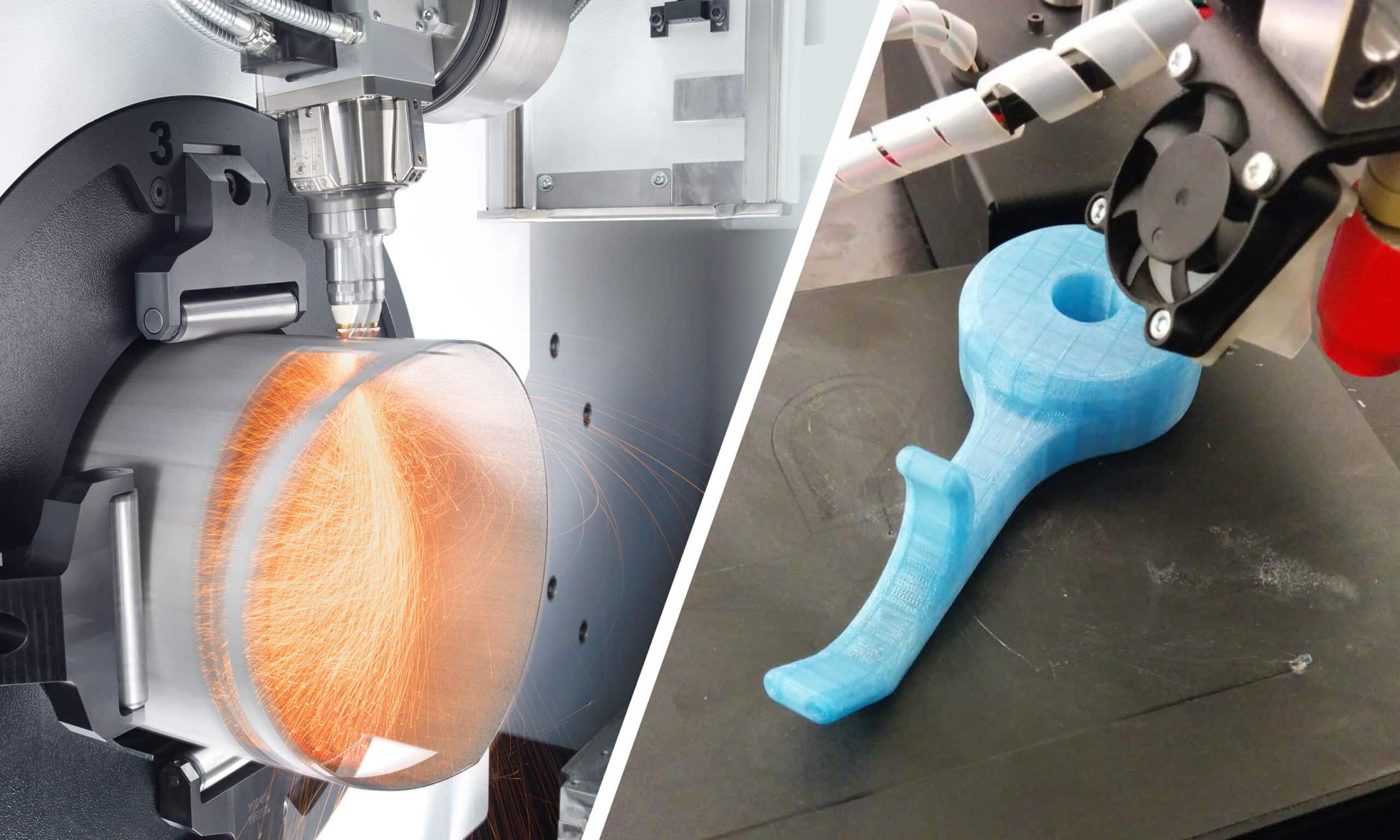

Our capabilities extend to complex shapes and contours, including bevel and countersink cuts, which eliminate the need for time-consuming weld preparation. This versatility allows us to meet the diverse needs of our clients across various industries.

Quality Assurance

Certified to ISO9001 and BS/EN 1090-1 standards, we guarantee reliable quality on even the most complex projects. Our commitment to quality assurance means our customers can trust us to deliver consistent, high-quality results every time.

Applications of Kerf Cutting

Kerf cutting is essential in numerous applications, from simple sheet metal parts to intricate 3D components. In tube laser cutting, for instance, our multi-axis machines along with Smart Design Production new design possibilities, reducing material costs and boosting downstream productivity. By minimising welding and assembly requirements, we help our customers streamline their manufacturing processes.

For sheet metal cutting, our industry-leading capacity allows us to handle intricate cutting, fine contouring, and tight nesting. This precision ensures reduced waste and less damage, making parts easier to extract and use.

Partner with Us for Your Kerf Laser Cutting Needs

At The Laser Cutting Co., we understand that precision and efficiency are critical to the success and efficiency of your project. Our investment in the latest laser cutting technologies, combined with our extensive experience, positions us as your ideal partner for all your kerf cutting requirements. From design to delivery, we work closely with our customers to ensure every project meets the highest standards of quality and performance.

Contact us today to learn more about our kerf laser cutting services and how we can help you achieve your manufacturing goals.