Open Section Cutting

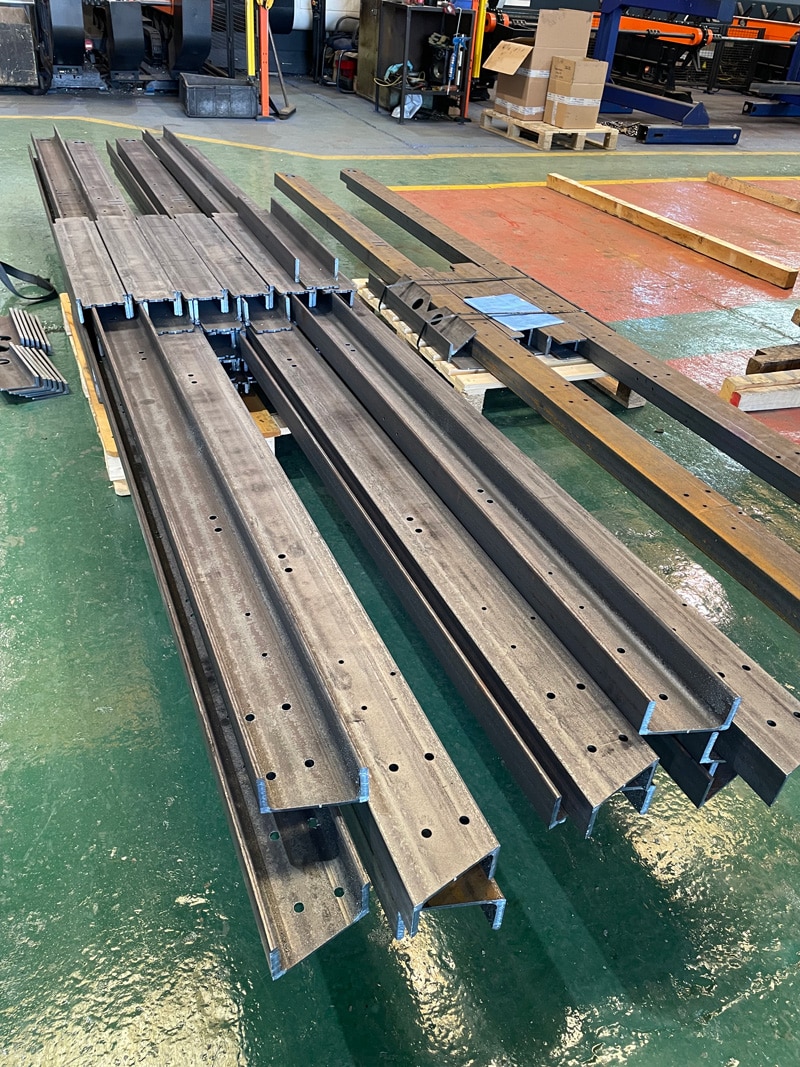

High complexity and high volume open section cutting.

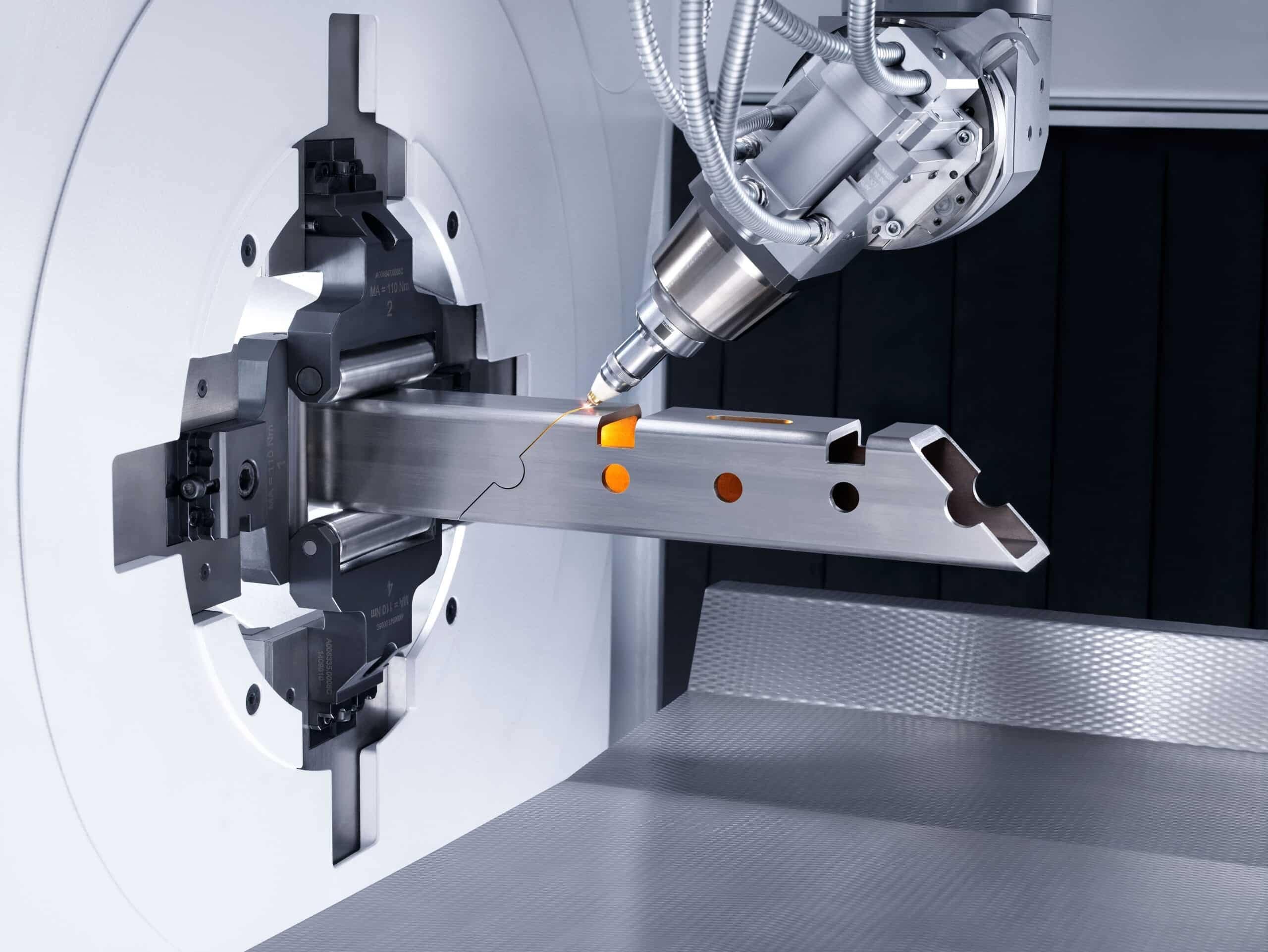

Outsource open section cutting to take advantage of state-of-the-art technology at The Laser Cutting Co. A suite of 3D laser cutting machines combined with 24-hour operation provides unrivalled capacity for rapid order turnaround.

6-axis laser cutters profile tube, hollow and structural sections up to 12000mm in length. Automated cutting delivers profiling accurate to +/-0.25mm with fast processing of large orders. Outsourced open section laser cutting with additional profiling capabilities, such as 60° bevelled contouring, deliver several key benefits:

- Aggregated buying prices

- Reduced weld prep

- Faster assembly

- Minimal reworks

- Rapid turnaround

- CE & UKCA Compliant

Efficiency

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

CE & UKCA Ready

6-axis laser cutting

Reduce weld prep

Fast assembly

50% time and cost saving

Rapid turnaround

Compliance

The Laser Cutting Co. are certified to ensure all laser cut parts conform to mandatory EU legislation and the Construction Products Regulation (CPR).

We conform to BS EN 1090-1:2009/A1:2011 standard for thermal cutting and profiling of steel and aluminium components. By conforming to this EU standard, we are able to provide CE and UKCA ready laser cut tube, box, section and sheet parts for steel structures in execution class EXC 1 up to EXC 3.

- BS EN 1090-1:2009/A1:2011

- CE and UKCA ready

- BS EN ISO 9001:2015

- Class EXC 1 to EXC 3

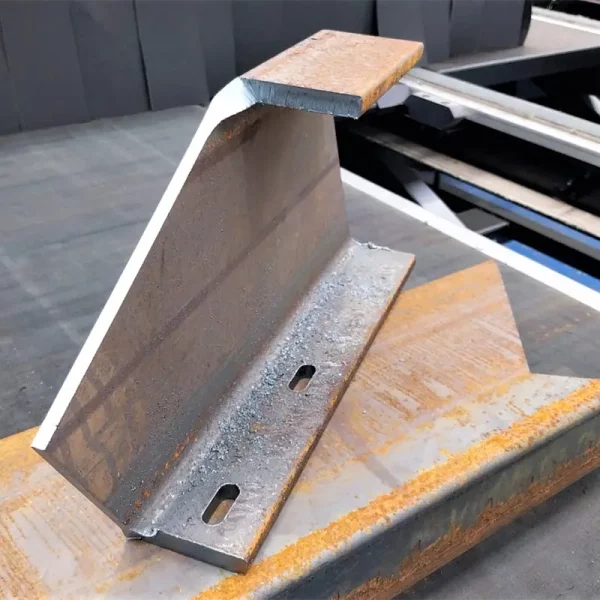

Structural Steel Profiling

A suite of 3D laser cutting machines handle all common box, tube and open profiles up to 12000mm in length with complex hollow tubes, angles and beam shapes all processed in house. The Laser Cutting Co. provide an unrivalled structural steel profiling service, with in-process extras to support fast and accurate assembly

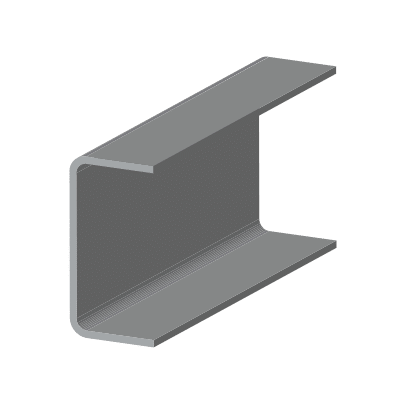

PFC

Channel

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 300 x 300mm |

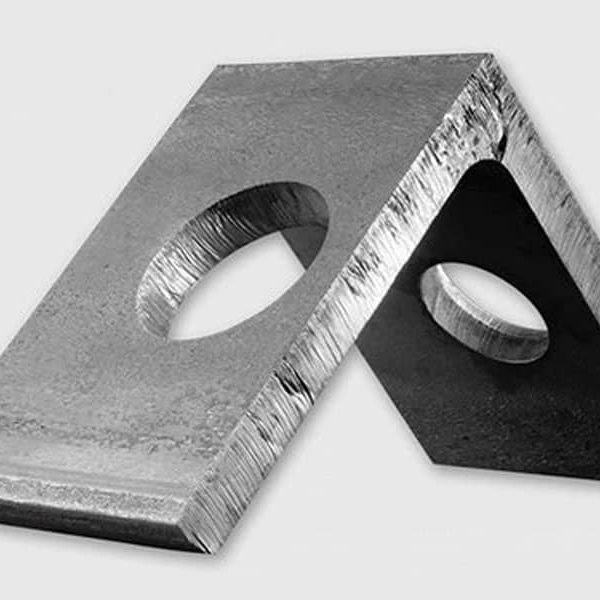

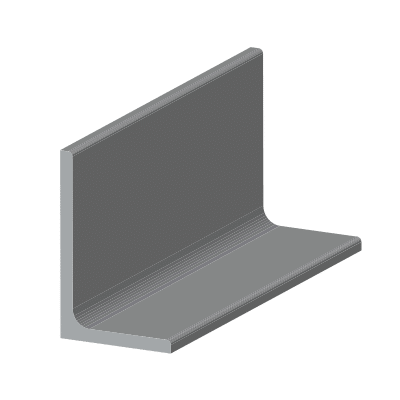

RSA

Angle

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 254 x 254mm |

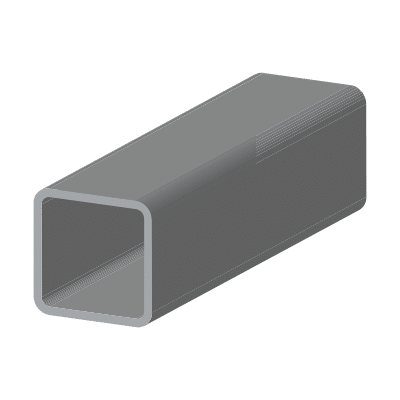

Rectangular &

Square Tubes

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 300 x 300mm |

Round Tube &

Pipe

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10mm | 406.4mm |

Universal

Beams

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 203 x 203mm |

Laser Cutting for Construction

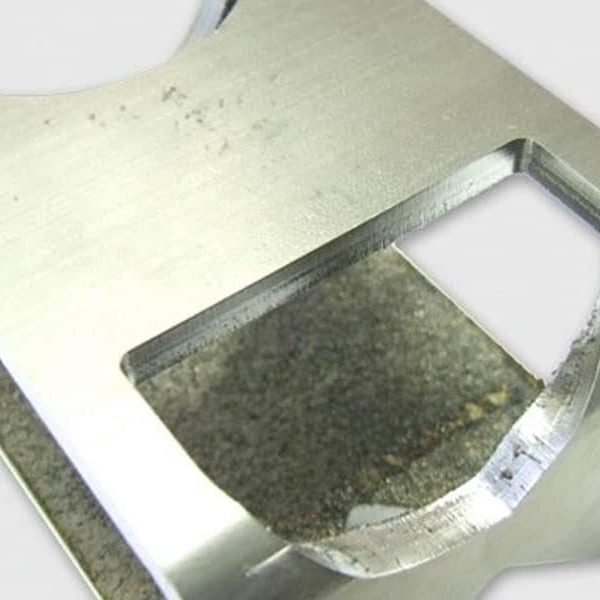

Quality profiling capabilities reduce downstream weld preparation and speed up assembly. The Laser Cutting Co. offers a range of added-value services designed to deliver a 50% reduction in production time and costs.

In addition to structural section cutting up to 12000mm long, a range of in-process services are available for both high and low volume jobs:

- 60° bevelled contours

- 45° bevels (inner and outer contours)

- Beam section drilling

- Countersinks (any size)

- Flowdrill and tapping.

A range of trusted services from approved partners, including polishing, powder coating, painting, and plating, are also available to The Laser Cutting Co. customers.

Quality Assurance

The Laser Cutting Co.’s Quality Promise

The highest possible quality standards with the after sales support to match

Our Factory Production Controls are in accordance with legally enforceable construction product regulation BS EN 1090 – Level 3, allowing intricate cutting of construction regulation profiles

Certified to BS EN ISO 9001:2015 for all profiling requirements

Open Section Cutting FAQ's

What is open section cutting?

Open section cutting refers to the process of cutting or dividing a section of a larger object that has an open or hollow shape. It typically involves cutting through the walls or edges of the open section to create separate pieces or components.

For more information regarding our Open Section Cutting services, contact The Laser Cutting Co. today.

What are some examples of objects that require open section cutting?

Objects that often require open section cutting include hollow pipes, tubes, channels, beams, and profiles. These objects are typically used in various industries such as construction, manufacturing, architecture, and infrastructure development.

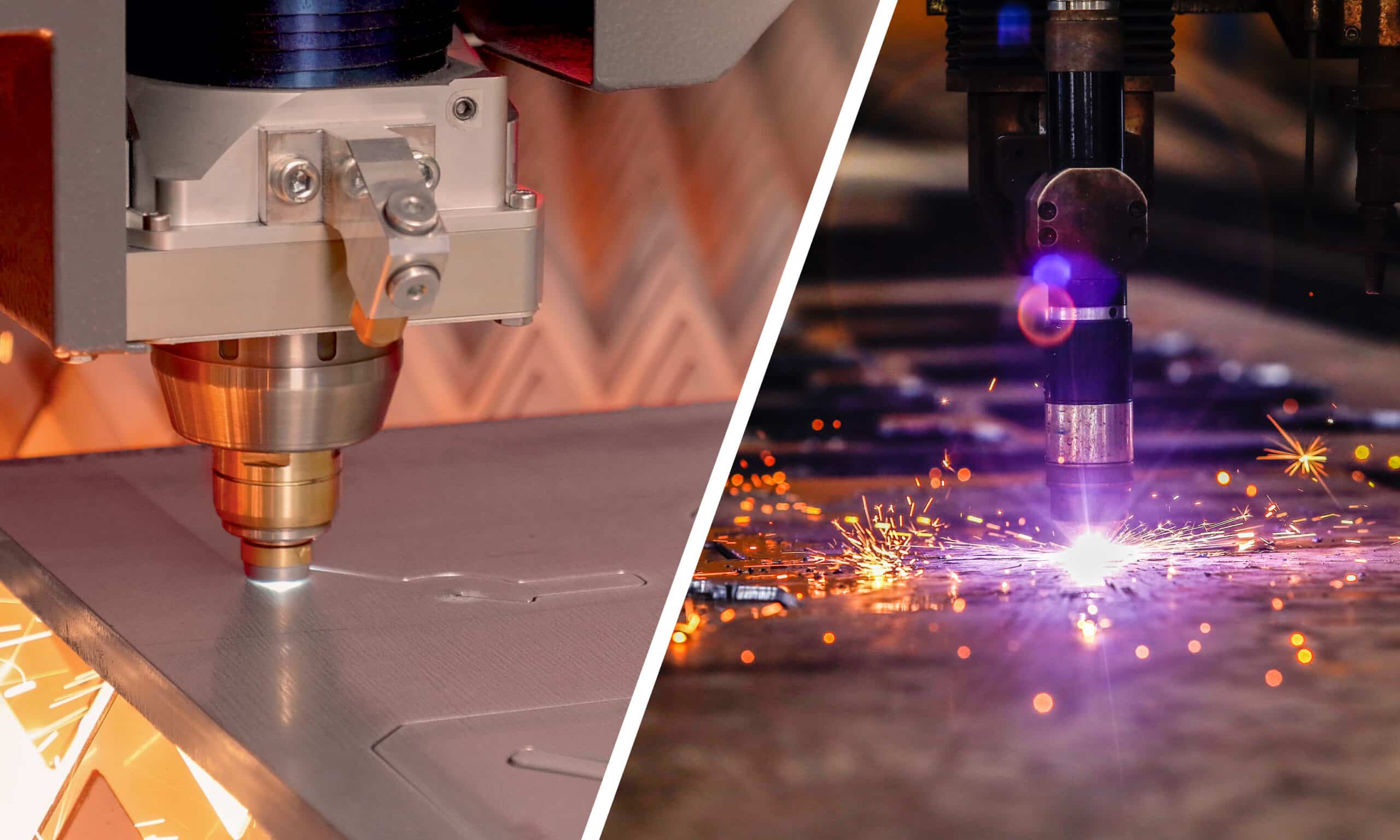

What are the common methods used for open section cutting?

Several methods can be used for open section cutting. Some commonly employed techniques include Laser Cutting, Plasma Cutting, and Waterjet Cutting. The specific method chosen depends on factors such as the material, thickness, precision requirements, and available equipment.

Contact The Laser Cutting Co. for a quote today.

What factors should be considered when choosing an open section cutting method?

When selecting an open section cutting method, factors like the material type, thickness, desired precision, cutting speed, heat-affected zone, and cost should be taken into consideration. Additionally, the specific shape and geometry of the open section may also influence the choice of cutting method.

For guidance regarding the most appropriate cutting method for open section parts, contact the team at The Laser Cutting Co. today.

Are there any special considerations for open section cutting?

Yes, open section cutting requires careful consideration of factors such as the wall thickness of the section, ensuring clean and precise cuts without damaging the integrity of the remaining structure, managing any burrs or sharp edges produced during the cutting process, and maintaining dimensional accuracy of the cut sections.

How can I find a reliable service provider for open section cutting?

To find a reliable service provider for open section cutting, you can research and contact companies specialising in metal fabrication, machining, or construction services. Consider their experience, equipment capabilities, certifications, customer reviews, and request quotes to compare pricing and services.

The Laser Cutting Co. is committed to providing an exceptional service no matter what. Contact us today for a quote, and see how our experts can help.