Precise, high-quality tube laser cutting service with rapid lead times and competitive prices.

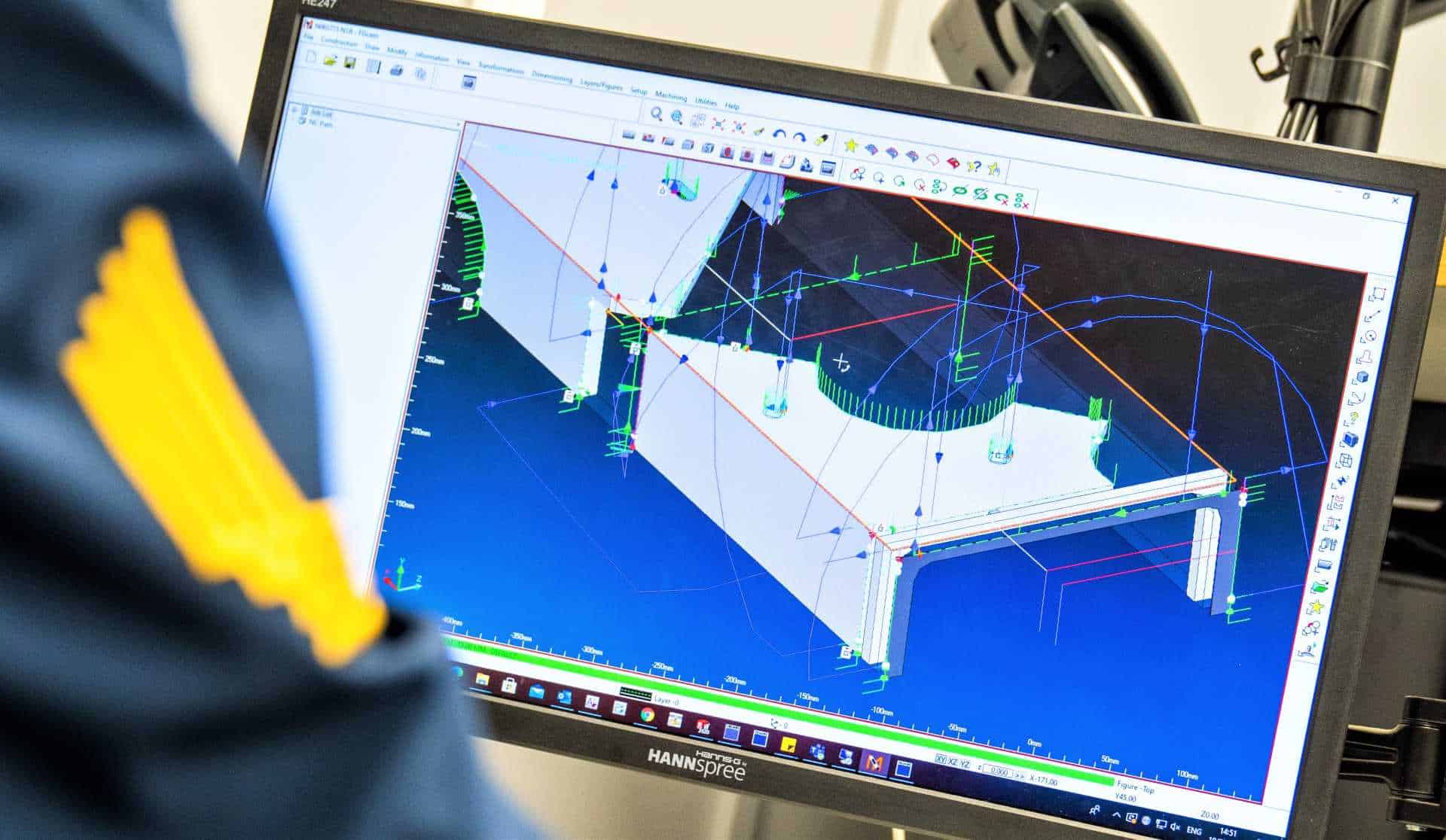

One of the UK’s leading tube laser cutting services, The Laser Cutting Co. boasts an impressive, state-of-the-art suite of laser cutting machines running 24 hours. Complemented by an in-house design team and end-to-end processing services, The Laser Cutting Co. tube laser cutting service is hard to beat.

No matter how large or small, simple, or complex your cutting requirements, your project is in safe hands with The Laser Cutting Co. Tube laser cutting – also known as 3D cutting – is proven to reduce material costs, increase downstream productivity, and deliver a competitive edge. Take advantage of our multi-axis tube lasers to open new design possibilities and optimise parts for highly efficient manufacturing.

Efficiency

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

6-axis tube laser cutting

Reduce component volume

Reduce pre-weld prep

Precise, fast assembly

New design possibilities

50% time and cost saving

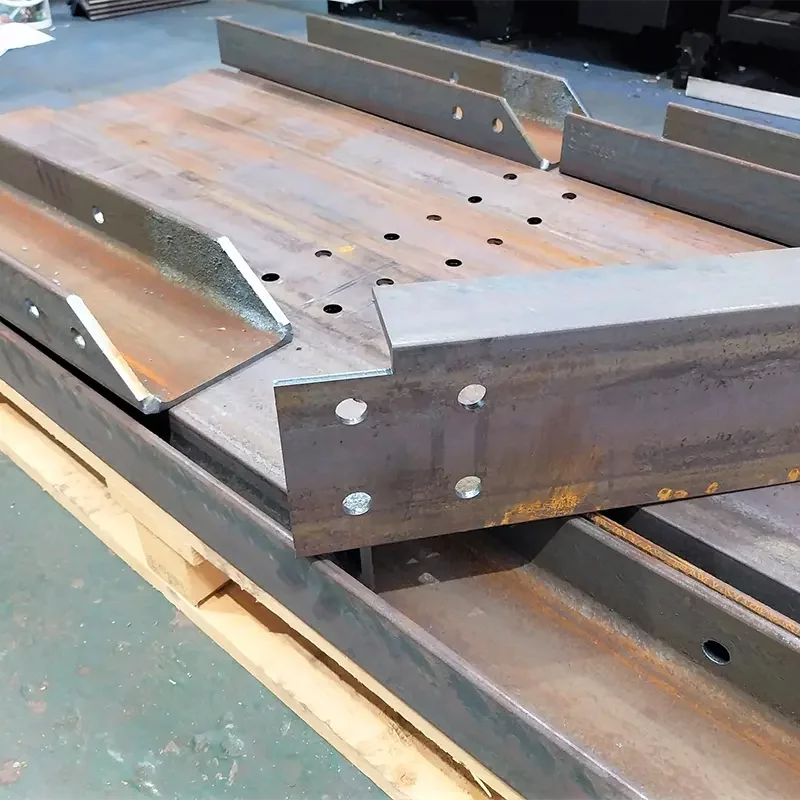

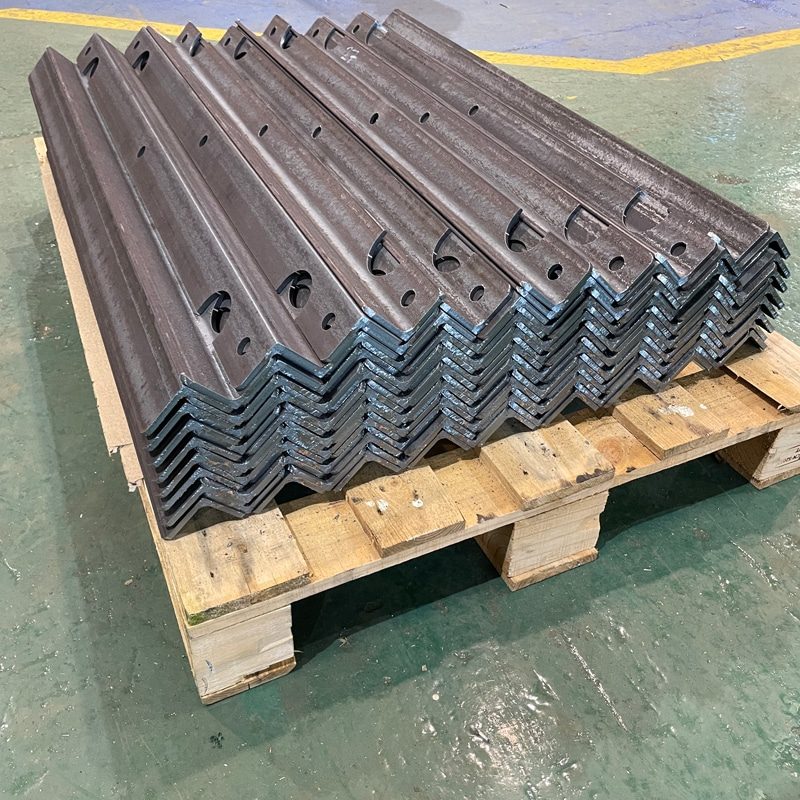

Tube and Section Laser Cutting

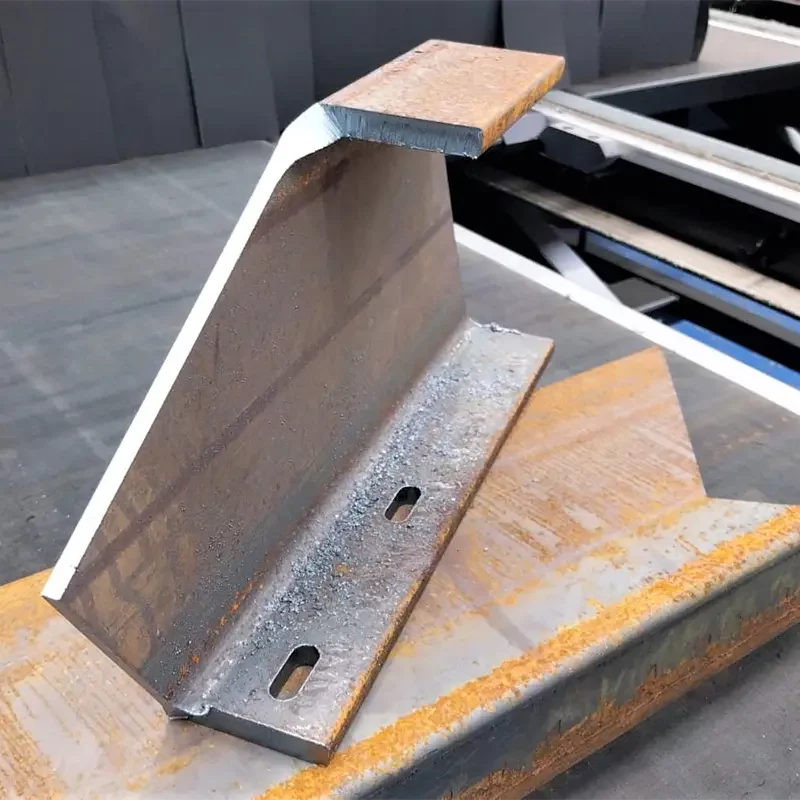

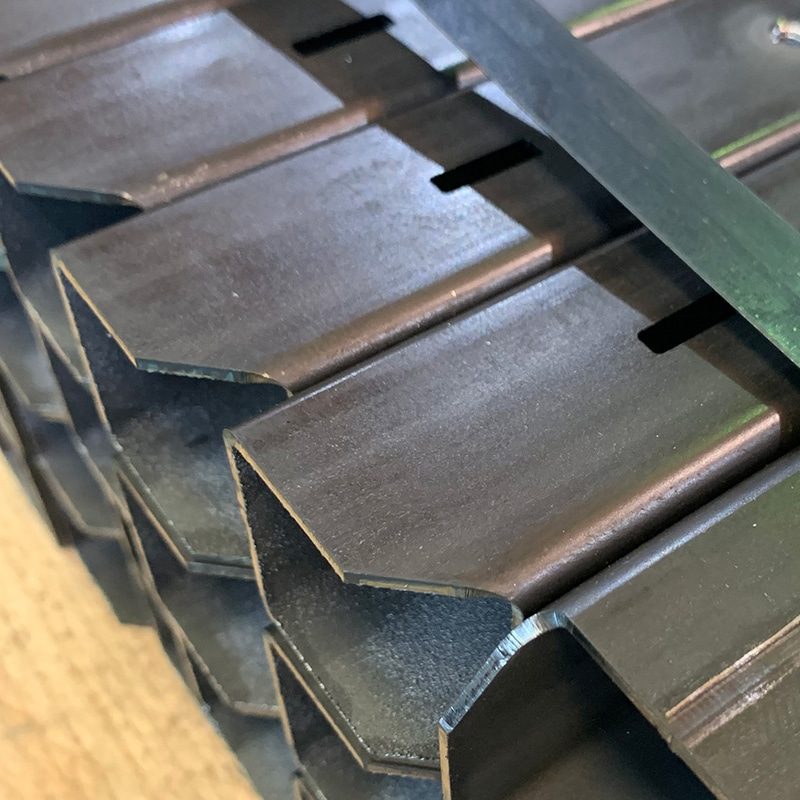

Our laser tube cutting service includes all major tube and section profiles – including large tube laser cutting – with specialist profile capabilities accommodated with ease. Continuous investment ensures we can always offer our customers the broadest capabilities, so they remain at the forefront.

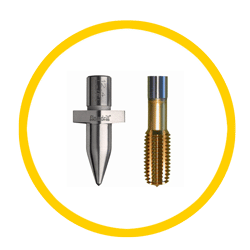

Take advantage of in-process bevel and countersink cutting and FlowDrill and tapping, available from The Laser Cutting Co. Receive your order fully weld prepped, including 45° chamfers in both inner and outer contours..

PFC

Channel

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 300 x 300mm |

RSA

Angle

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 254 x 254mm |

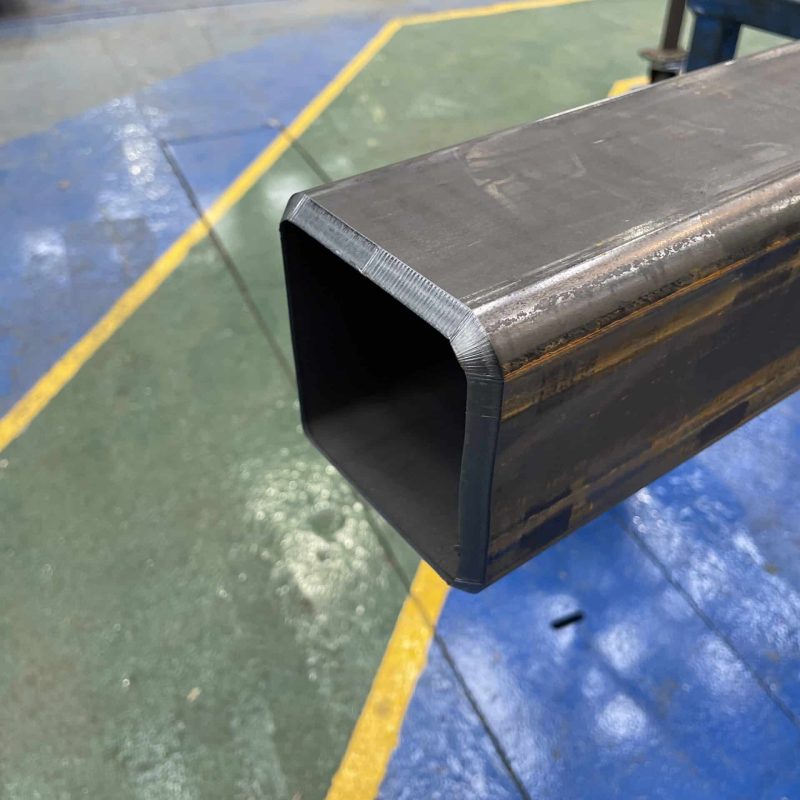

Rectangular &

Square Tubes

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 300 x 300mm |

Round Tube &

Pipe

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10mm | 406.4mm |

Universal

Beams

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 203 x 203mm |

![Tube Laser Cutting [DRAFT] - The Laser Cutting Company](https://www.lasercutting.co.uk/wp-content/uploads/csm-TruLaser-Tube-7000-fiber-T07-sensor-system-a0d4c09b35-a516508a2a-1.jpg)

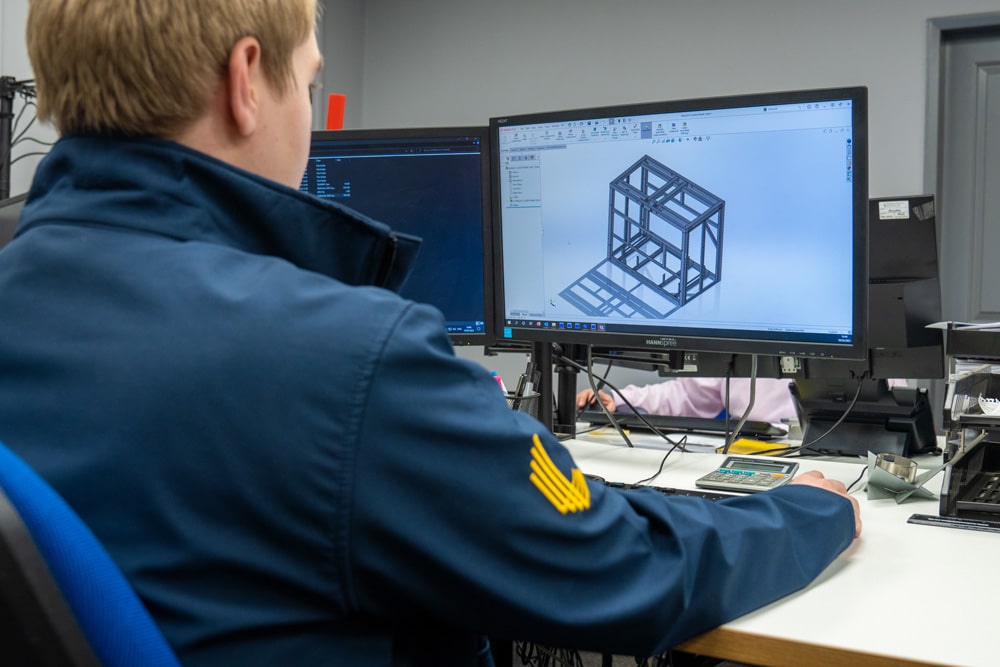

Maximising Productivity – TruLaser Tube 7000 Fibre Machine

As one of the very first in the UK to invest in this industry-defining technology, The Laser Cutting Co. is proud to announce our latest machine investment – the TruLaser Tube 7000 Fibre Machine; providing unrivalled lead-times, competitive pricing, and more than doubling our existing tube laser cutting capacity.

Offering fast and flexible processing, this machinery provides laser power of up to 6kW for material thicknesses up to 15mm, rapid processing of section parts up of to 254mm outside diameter, and features Bevel Cut and RapidCut technology, Seamline Tube Detection and brass and copper cutting.

Additional Specifications of our new TruLaser Tube 7000 Fibre Machine

- Raw material max load length – 9.2m

- Finished part max length – 6.5m

- Max outside part diameter – 254mm

- Max mild steel thickness – 15mm

- Max stainless steel thickness – 12mm

Advanced Tube Laser Cutting

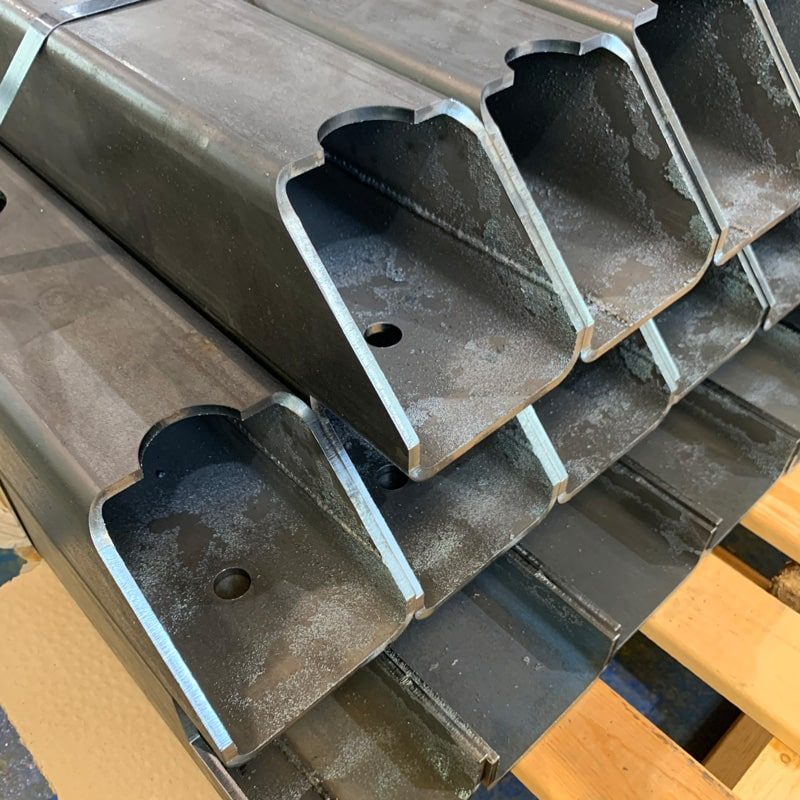

Part optimisation is reaching unprecedented levels of efficiency thanks to the availability of 6-axis 3D cutting. The ubiquitous nature of tubes and profiles ensure a broad scope of opportunity to design more profitably. The ability to reduce materials, processes such as welding, and improve assembly times, are revealing routes to new markets for manufacturers.

Cutting, welding, milling and deburring processes add cost to a project. Access to a 3D laser tube cutting machine means designers have the ability to reduce processes for faster lead times and lower costs. Average cost reduction is around 50% with 85% cost reductions common.

Need a hand? Maximise efficiency through design, with The Laser Cutting Co.’s in-house design service. We can fully optimise part design for efficient manufacturing and downstream assembly.

Single part designs

Part

folds

Self-Jigs

Slot and tag

Flow drilling

Our Investments, Your Benefit

We offer over 30 years of tube laser cutting and design experience for our customers to take advantage of. Add to this, an ever-evolving suite of world-class technology, for an unbeatable laser cutting service.

As a Factory Production Control (FPR) certificate holder every project receives The Laser Cutting Co. quality assurance. We specialise in fully outsourced, end-to-end services, and everything in between. A true one-stop-shop, The Laser Cutting Co. offers an unrivalled range of in-house services and trusted partners to get the job done, fast.

Join up your supply chain with access to a selection of key services from our trusted partners.

Our in-house Cutting Services:

- Tube laser cutting (3D cutting)

- Large and open section cutting

- 2D flatbed laser cutting

- Smart design service

- Flow drilling

- Waterjet cutting

- Flame cutting

- Weld preps

- Profile bending

Tube Laser Cutting FAQ's

What is tube laser cutting?

Tube laser cutting is a method of utilising lasers to manipulate and cut hollow bar and tube, including structural sections and channels. A precise technique, tube laser cutting is an effective way of cutting a variety of materials, profiles, shapes, and sizes to exact specifications.

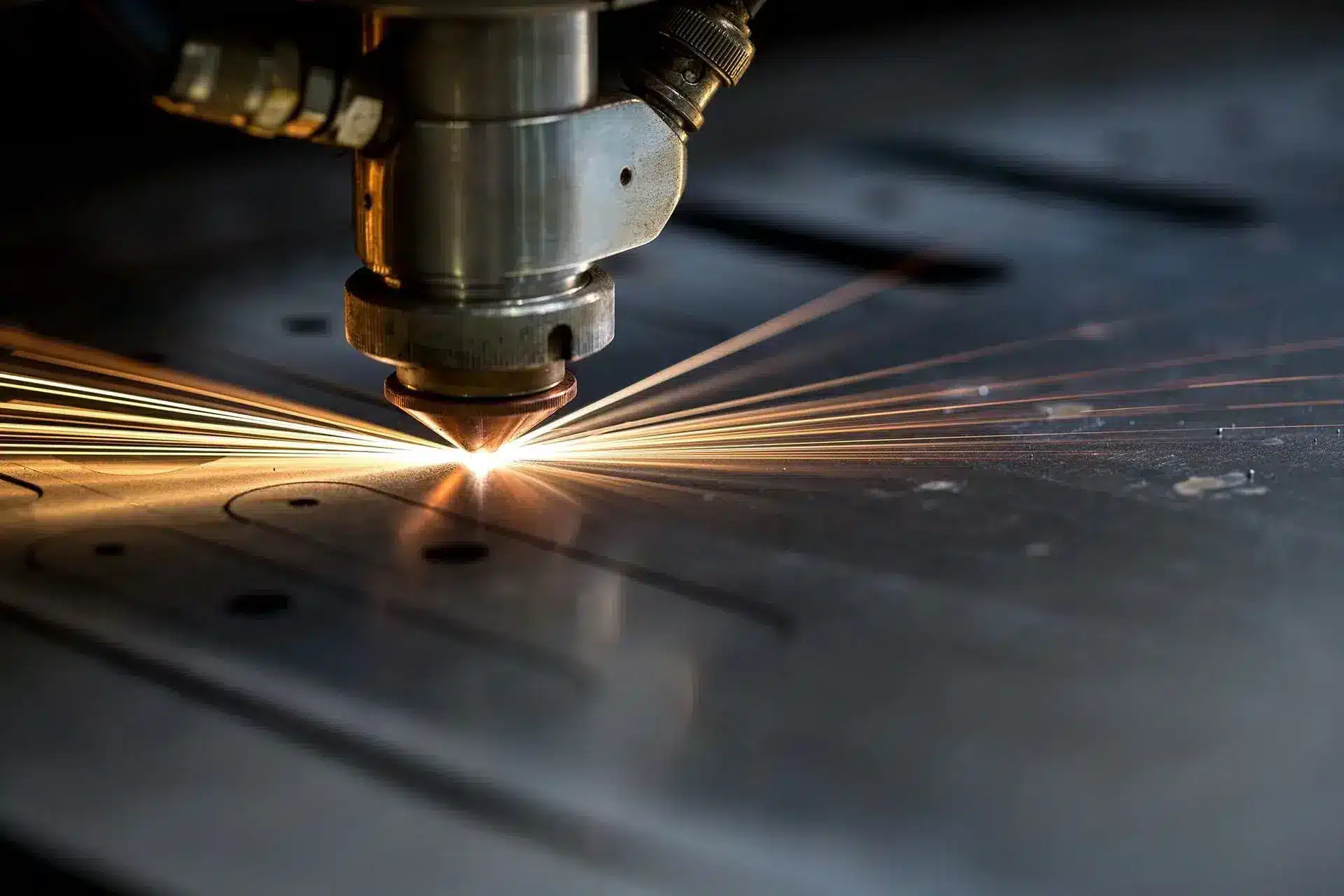

How does tube laser cutting work?

Utilising a high-powered laser and computer-aided design (CAD) software to ensure repeatable and accurate cuts, laser energy is used to melt and/or vaporise away material and create precise and narrow cuts in tubes, structural sections, and profile channels.

What are the advantages of laser tube cutting?

Laser tube cutting hosts a range of advantages, some of which include

- Exceptional precision and accuracy:

Laser technology allows for precise and intricate cuts, ensuring tight tolerances to +–.25mm and excellent finish quality - Versatility: Extremely versatile, tube laser cutting technology enables a wide range of materials to be cut in a variety of complex configurations through 5 axis cutting.

- Efficiency: A quick and efficient process, tube laser cutting reduces production times and costs significantly.

- Minimal Distortion: Using a highly-focused laser minimises heat-affected areas, including warping and distortion.

- Complex shapes and designs: Tube laser cutting ensures the creation of complex shapes, designs, and configurations that other methods are simply not capable of.

What types of tubes can be cut with a tube laser?

Tube laser cutting allows for various types of tubes and parts to be cut in a range of configurations, including round, square, and even custom profiles. They can also handle a variety of sizes and thicknesses depending on tube laser cutting capabilities. For bespoke projects, contact The Laser Cutting Co. for more information.

What industries utilise tube laser cutting?

Tube laser cutting offers a multitude of applications, typical industries include

- Automotive and transport

- Architecture and construction

- Furniture and interior design

- Manufacturing and fabrication

How can I choose the right tube laser cutting service provider?

When selecting a tube laser cutting service provider, you should consider the following factors

- Experience and expertise

- Technology and capabilities

- Quality, certifications and precision

- Material and design flexibility

- Turnaround time and cost

- Trust and reliability

How much does laser cutting cost?

The costs of laser cutting can vary greatly depending upon certain factors, including materials, the time required for cutting, level of detail, delivery, and labour. Here at The Laser Cutting Co., 24-hour production paired with our suite of industry-defining laser cutting machines ensures that we are able to provide incredible lead times and provide thorough and cost-effective solutions.

For a bespoke laser cutting quote, get in touch with The Laser Cutting Co. today.

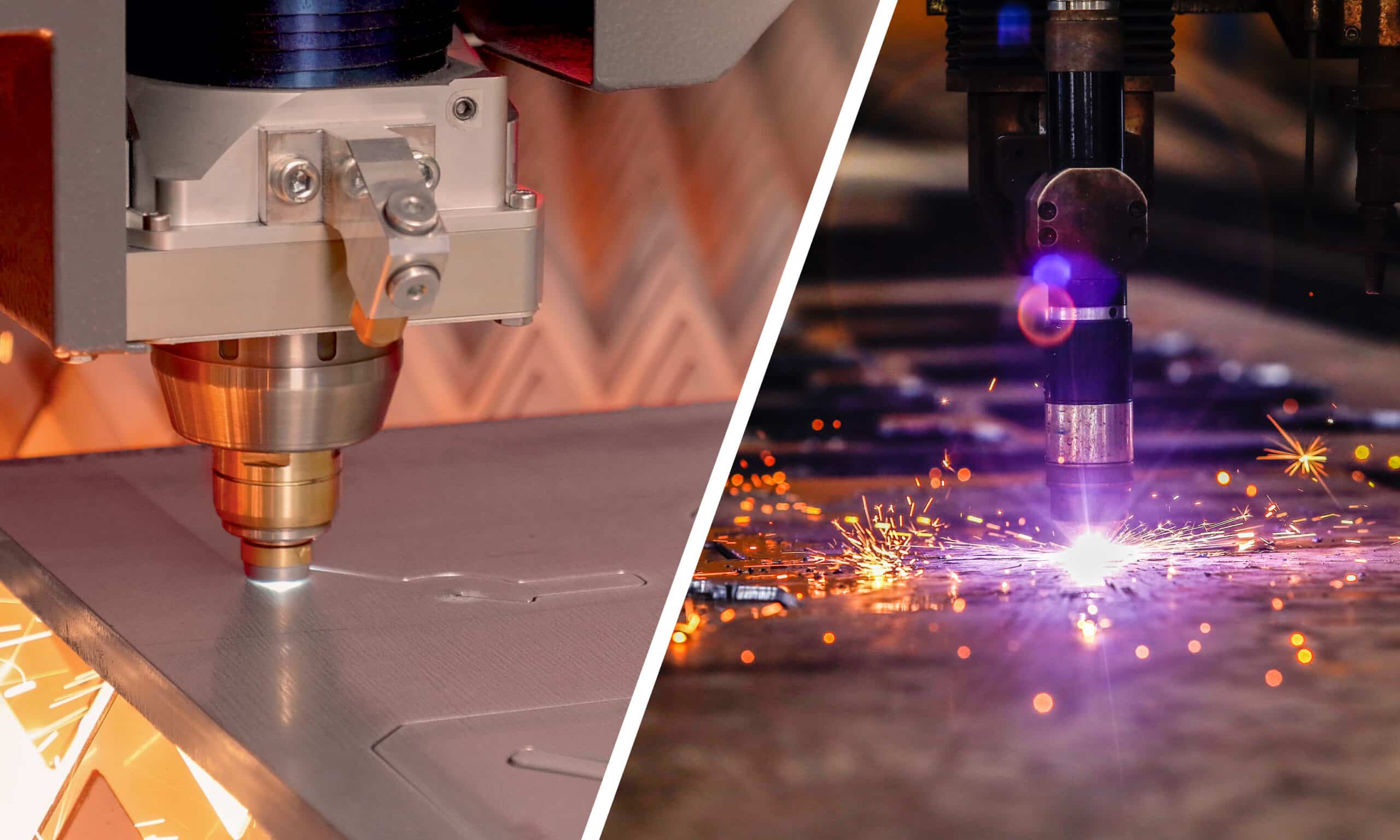

What are the main types of laser cutting?

The three major types of laser cutting include:

- Fusion Cutting – a cutting technique that cuts metal by melting them and then blowing out the molten remnants using a high-pressure stream of inert gas.

- Remote Cutting: involves cutting very thin and delicate materials without the use of gas, as the laser itself is able to evaporate the material away.

What are 8 processes of a laser cutter?

Laser cutters are capable of the following…

- Perforating

- Cutting

- Etching

- Seaming

- Engraving

- Welding

- Marking

- Drilling

How precise is laser cutting?

The kerf of a laser cutting machine is considerably thinner than the kerf of a sawblade, so is therefore capable of extremely detailed and refined cutting when compared to other methods of material cutting; with a cutting tolerance of +-0.25mm.

What is the maximum size and thickness for laser cutting?

At The Laser Cutting Co., our laser cutting tolerances are unrivalled. With our professional suite of laser cutting machines, we are able to process sheet metal sizes up to 2500mm x 6000mm, and up to 50mm thick.