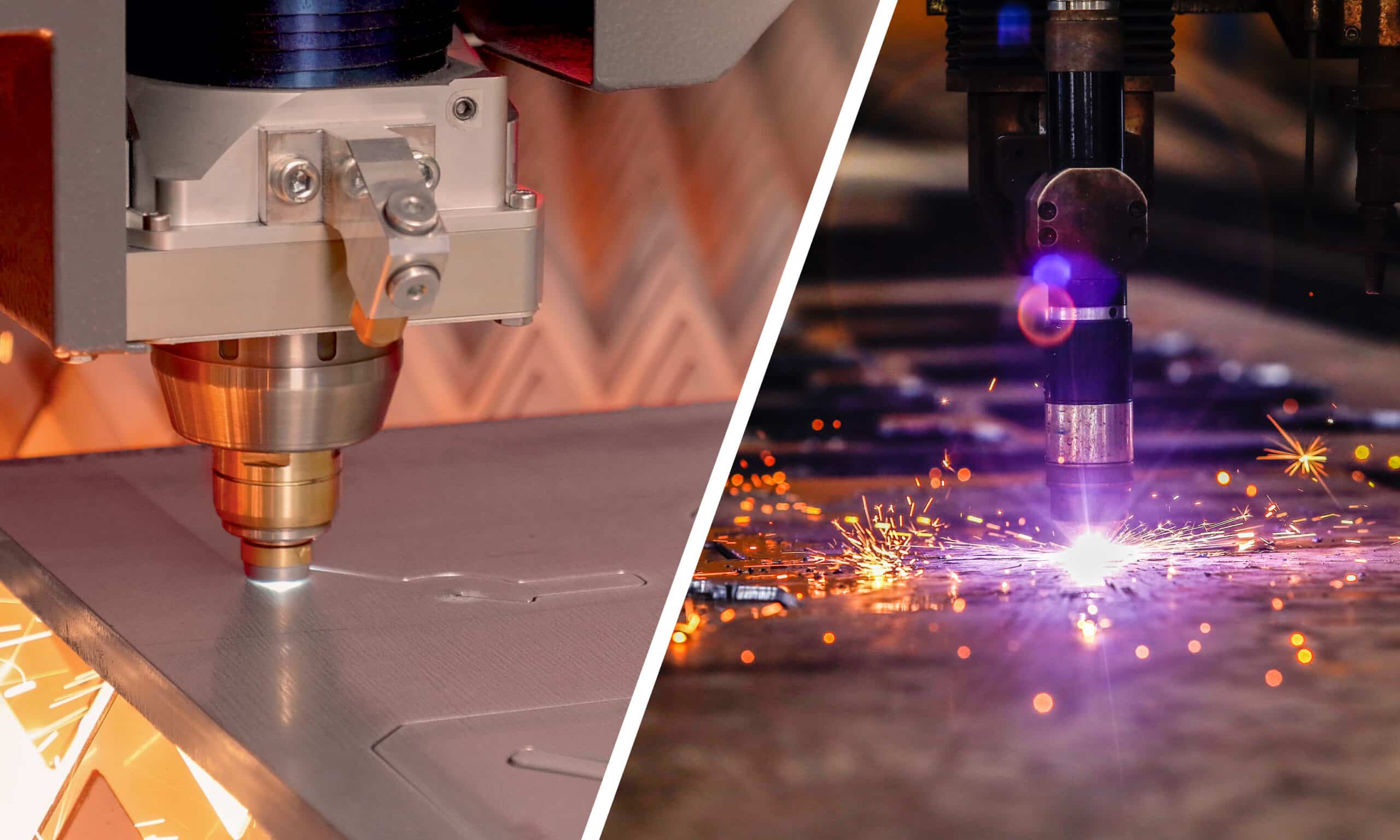

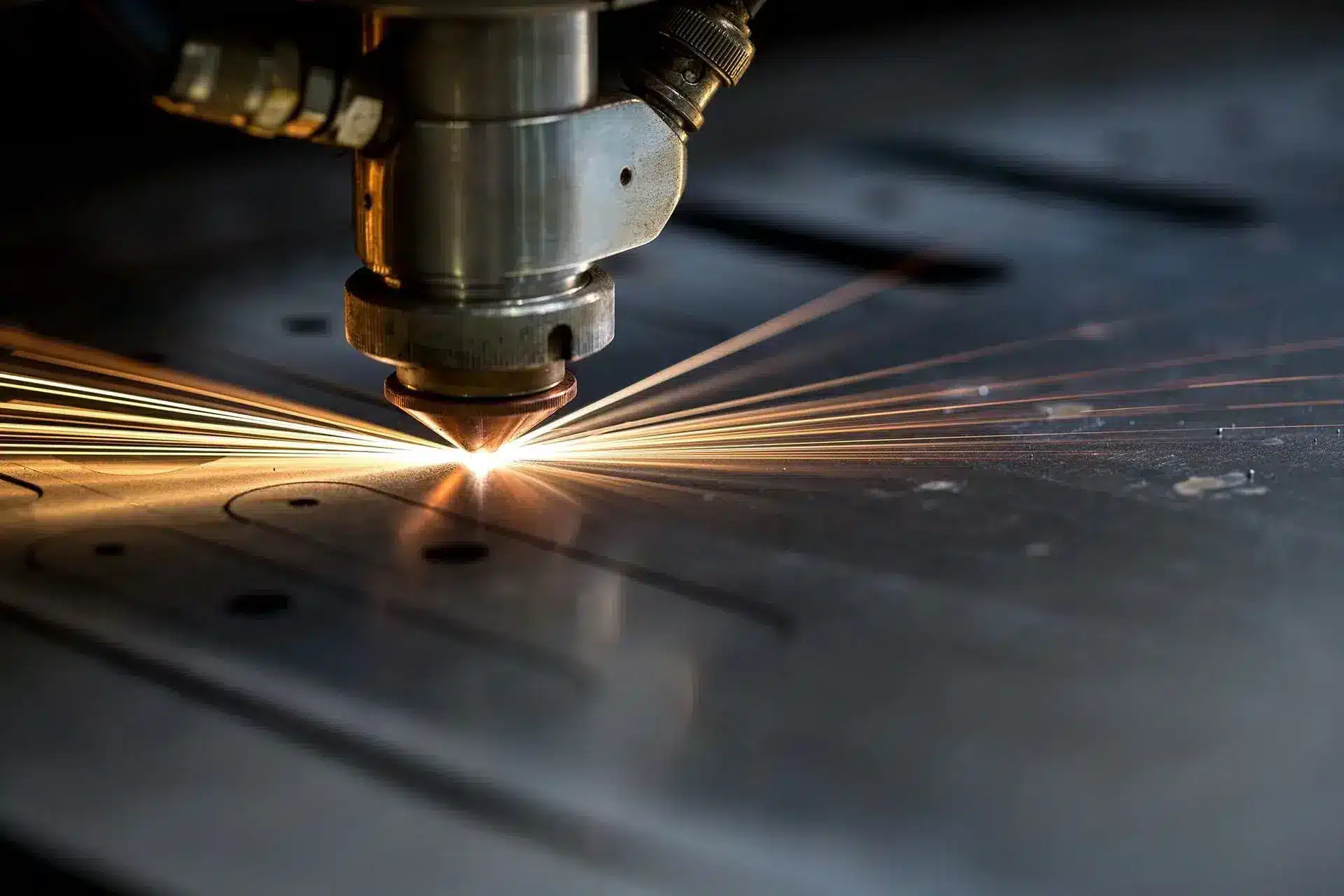

Established in 1981, we here at The Laser Cutting Co. understand more than most, that when it comes to manufacturing, the keys to success lie in enhancing efficiency, precision, and overall productivity. With our state-of-the-art flow drilling and tapping services, we aim to optimise your assembly processes, reduce material waste, and improve cost and time efficiency.

What Is Flow Drilling and Tapping?

Flow drilling is a cost-effective alternative to conventional fastening techniques. Using a specialised tool, the flow drill is intricately manoeuvred into the material at high speeds; this precision process produces controlled friction and heat, resulting in a resilient and uniformly secured fixing.

The subsequent stage involves tapping, a meticulous threading process that maximises the available surface area, our tapping services establish a secure and reliable connection within assembly. The combination of flow drilling and tapping not only enhances the structural integrity of the components but also ensures a meticulous and dependable assembly process.

How Flow Drilling and Tapping Optimises Assembly Processes

Strengthening Connections

Flow drilling and tapping harness existing materials to forge robust and uniform fixings, significantly reinforcing connections within the assembly. This dual approach not only improves the structural integrity of the finished product but also enhances the overall reliability.

Minimising Waste

Flow drilling and tapping significantly reduce waste, aligning with sustainable manufacturing practices. The minimal waste generated in these processes contributes to a more environmentally friendly production approach, meeting the demands of responsible and conscious manufacturing.

Cost and Time Efficiency

The amalgamation of flow drilling and tapping results in a potential reduction of up to 50% in production time and costs. This economic advantage has far-reaching implications for industries looking to enhance their bottom line without compromising on quality.

Precision in Every Detail

With a commitment to laser cutting tolerances of +-0.25mm, our flow drilling and tapping services at The Laser Cutting Co. ensure unparalleled precision in the assembly process. This precision is not just a goal but a guarantee, allowing manufacturers to produce components with exacting specifications.

Risk Mitigation

Flow drilling and tapping eliminate the risks associated with alternative fixings, preventing issues like spinning or breaking. This risk mitigation occurs both during the tapping stage and in the final assembled product, fostering a more reliable and durable result.

Versatility Across Material Applications

The Laser Cutting Co.’s flow drilling and tapping services extend across an array of materials, including mild steel, stainless steel, copper, brass, bronze, and aluminium. This versatility positions these services as indispensable across various industries, from automotive to aerospace.

Integral Components of Smart Design Production

Flow Drilling and Tapping seamlessly integrate into The Laser Cutting Co.’s Smart Design Production process. This innovative approach not only ensures the accuracy and reliability of parts but also facilitates a more efficient production line.

The Laser Cutting Co. – Redefining Manufacturing Excellence

Our commitment to excellence at The Laser Cutting Co. is exemplified by our fully comprehensive manufacturing processes, and we are proud to be at the forefront of innovative manufacturing; providing industries with a competitive edge. Our cutting-edge flow drilling and tapping facilities epitomise streamlined assembly processes, enabling the delivery of top-tier products with unparalleled efficiency and precision.

For more information and guidance regarding our flow drilling and tapping services, please contact our team of experts at The Laser Cutting Co. today.