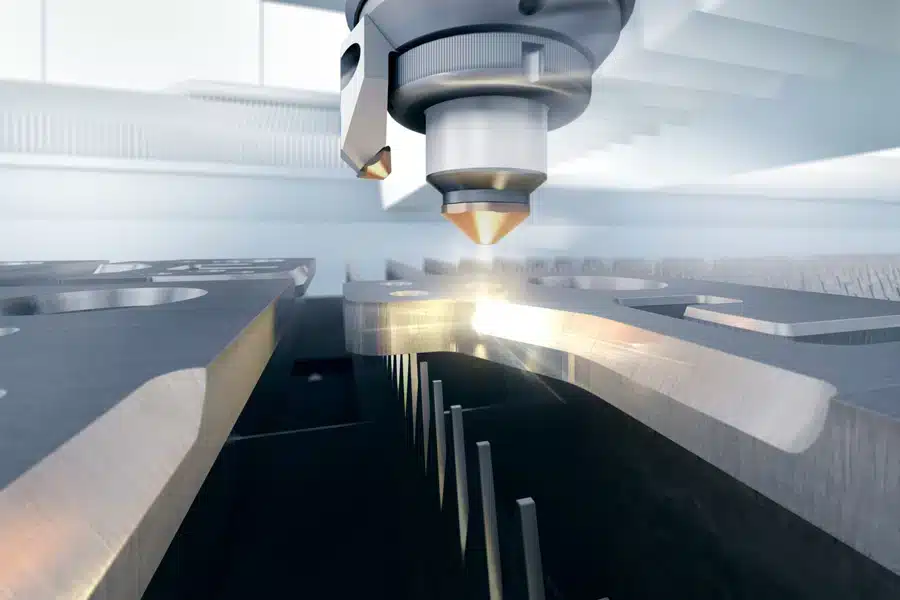

Exceptional Hardox Steel Laser Cutting

Hardox steel is a brand of incredibly hard-wearing and high-strength materials that is renowned for its remarkable properties. Due to its robust characteristics, Hardox steel is commonly utilised in heavy industrial settings, most notably in mining, construction, agricultural, and military applications.

Hardox steel achieves its strength through tailored chemical formulations, alloy additions, and tempering processes that form a fine microstructure through high-heat and cold rolling, establishing exceptional hardiness without succumbing to brittleness. Different grades of Hardox can be developed through various element formulations and heat treatments, depending on the type of application.

At The Laser Cutting Co., we provide a fleet of market-leading laser beds which can cut through Hardox steel with ease across a range of geometries and large-scale projects. Our services can accommodate both thermal and cold-cutting processes, such as waterjet, to achieve burr-free edges without additional finishes. Our services are complemented by in-house smart design production and stringent quality control.

Why Trust The Laser Cutting Co. for Galvanised Sheet Cutting?

Efficiency

CNC fibre laser cutting machines operate 24 hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on even the largest and most complex projects.

Experience

Over 40 years of laser profiling experience using the latest cutting technologies. Our investments, your benefit

High Tensile Strength and Reliable Results

Beyond its durability, Hardox steel demonstrates impressive adaptability, consistently performing under demanding and challenging conditions, such as military applications. The combination of tensile strength, high impact resistance, and structural integrity results in components delivering a far greater service life, reducing the need for repairs or replacements.

Hardox steel’s ability to maintain its properties over time also contributes to increased operational efficiency and reduced downtime. In many situations, the performance of Hardox steel eliminates the need for additional protective finishes or reinforcements, streamlining the design and profiling process.

Hardox Steel Applications

Hardox steel is mostly used across heavy applications where abrasion resistance is essential. Hardox applications include, but are not limited to:

- Mining: Chute liners, conveyor skirt boards, screens, excavators, and dumper buckets.

- Construction & Transport: Demolition equipment components, dump truck bodies, and liners.

- Industrial: Crusher parts, industrial blades, feeder liners, recycling equipment, crushers and mills.

- Military & Defence: Ballistic barriers, vehicle armour, structural components.

DYNAMIC Bevel, Countersink, and Weld Preparation Laser Cutting

- 50 degree bevel cutting on top and bottom edges

- 6510mm x 2600mm cutting bed

- Complex bevel geometries in up to 40mm thick material

Hardox Steel Grades

Hardox is available in various grades depending on the formulation and thermal process. Some common grades include:

Hardox 400

Offers good wear and damage resistance with excellent formability.

Hardox 450

Increased hardness and wear life, while still maintaining flexibility.

Hardox 500

Designed for high-performance parts that require great strength.

Hardox 500 Tuf

Offers even more resistance to cracking under pressure.

Hardox 550

Delivers additional hardness in contrast to Hardox 500.

Hardox 600

Provides excellent strength in harsh and demanding environments.

Hardox HiAce

Specialised performance for acidic wear applications.

We can laser-cut sheets in numerous grades and depths to meet your expected project requirements.

Sheet Metal Laser Cutting Thicknesses

Material Thickness (mm)

What are the Benefits of Laser Cutting Hardox Steel?

Laser cutting delivers reliable and consistent results across Hardox steel components. Some advantages of laser cutting Hardox include:

Unparalleled Precision

Laser cutting operates within highly fine tolerances, ensuring components, such as wear plates, fit precisely.

Remarkable Versatility

Our laser cutters can seamlessly handle complex geometries and intricate designs across small and large-scale projects.

Exceptional Edge Quality

Our highly powered laser beams produce smooth and burr free edges with ease, reducing the need for secondary finishes.

Contactless Process

Laser cutting ensures there is no contact between the material and the cutting tool, ensuring no damage or contamination to the material.

Structural Integrity

Thermal cutting processes don’t compromise the strength or integrity of Hardox due to its durable structure.

Reduced Waste

CAD nesting techniques and advanced lasers are highly effective at reducing material wastage and saving costs over time.

Waterjet Bevel Cutting

Waterjet and waterjet bevel cutting are highly effective at cutting Hardox and armour plates without generating heat-affected zones (HAZ). This is particularly advantageous for defence sectors that rely on streamlined, consistent processes without the risk of material distortion, which can greatly affect structural integrity and precision.

Additionally, our skilled operators can control the level of flow and abrasive of waterjet cutting to offer high-quality edges and bevels in one single process, minimising the need for secondary finishes, saving time and cost.

Laser Bevel and Countersinking

When profiling high tensile materials such as Hardox steel, bevel cutting and countersinking are crucial in delivering clean joints and flush fixings for heavy-duty applications. Establishing recessed areas allows bolts and fasteners to sit at surface level, improving both structural integrity and achieving a polished finish.

Our progressive laser cutting systems can produce highly precise bevels and countersinks as a standard procedure within the fabrication process. This eliminates the need for secondary machining, effectively reducing lead times and ensuring each Hardox component is installation-ready to exceptional standards.