Key Takeaways

- Precision laser cutting offers exceptional accuracy, reducing waste and improving production time.

- Techniques such as nesting and automation reduce material waste, supporting sustainable manufacturing.

- Investment in advanced technology delivers high-quality and competitively priced services.

The landscape of metal manufacturing is consistently evolving alongside advanced technology, and the demand for high precision at competitive rates is steadily increasing. Due to recent initiatives, businesses are also seeking new and innovative ways to offer sustainable services without hindering the quality of execution. At The Laser Cutting Co., our continuous investment in laser technology has allowed us to achieve exceptional precision cutting that reduces waste and expedites lead times across every project.

Why Combatting Material Waste is Important

The future of laser cutting places responsible manufacturing at the forefront, resulting in great emphasis on streamlined and economic processes. Wasted material is also considered an environmental concern, with additional discussion surrounding the high energy use and fumes released during production. Techniques such as nesting can combat this issue, helping to use as much material as possible, which not only drives down energy use but also accelerates turnaround times. Maximised material yield can allow businesses to benefit from:

- Reduced production costs

- Lower carbon footprint due to minimal offcuts

- Reliable consistency in repeat parts and assemblies

- Sustainable operations that support net-zero goals

This is particularly beneficial for industries that are working at scale or on costly materials, ensuring long-term value is retained as less material is wasted.

How Precision Cutting Has Transformed Manufacturing

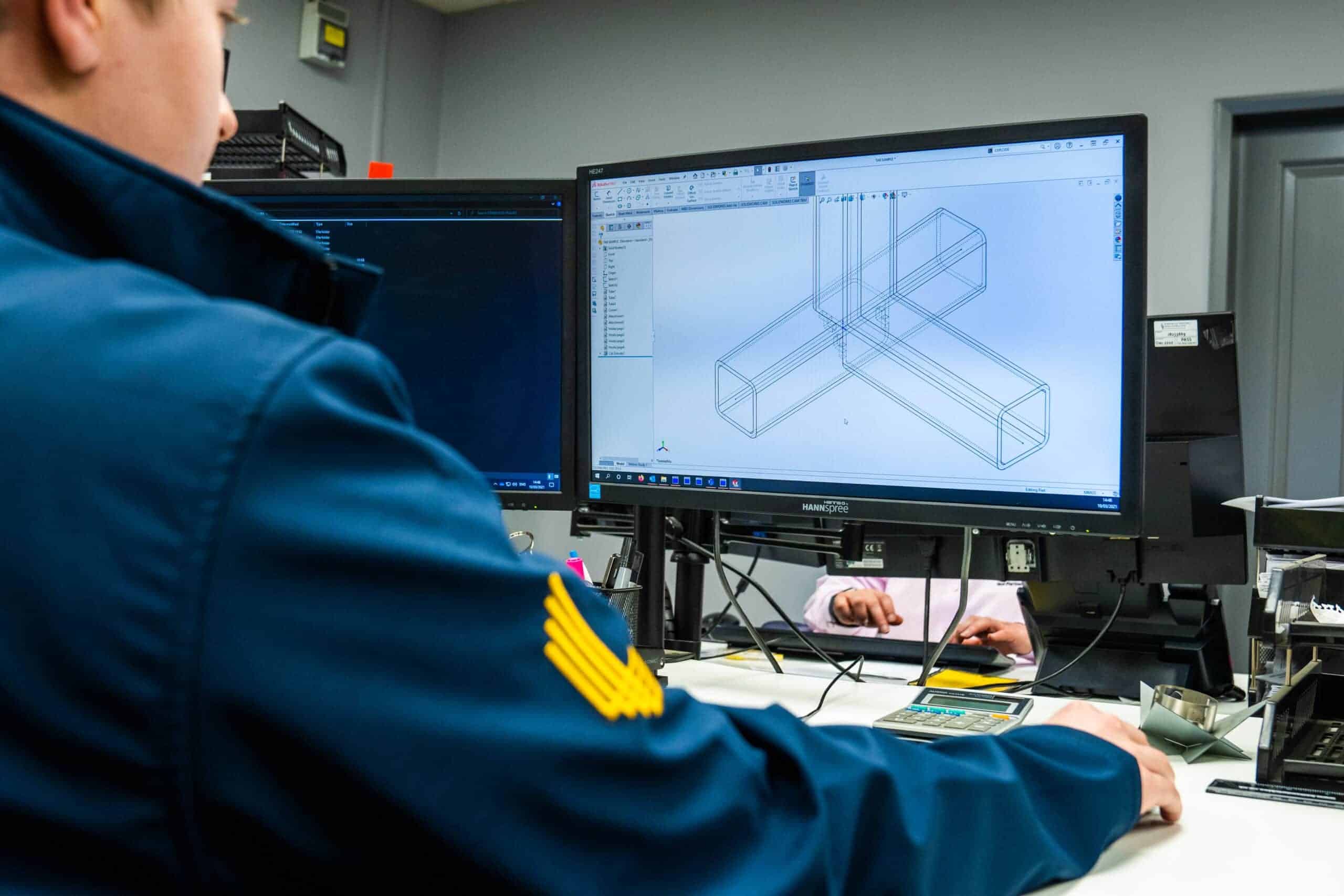

Advanced techniques, such as laser, waterjet, and plasma cutting, are completely designed to deliver maximum efficiency and minimal waste. Utilising modern smart design production and real-time systems across the production process can ensure each part is cut accurately and consistently on pre-planned paths. CAD machines use intelligent software to nest parts, all without secondary machining and finishes, achieving detailed designs effortlessly. At The Laser Cutting Co., our fleet of systems is calibrated to cut within ±0.25mm tolerance, effectively reducing rework and scrap rates.

Precision Cutting Within Open Section Cutting

Processes such as laser cutting are applicable and excellent across all types of materials and sectors, and one area where it stands out is in heavy open section cutting. When working with channels, beams, or box sections, each cut requires careful preparation and control to maintain material strength, alignment, and integrity.

- Perfectly aligned weld preps and reduced post-processing

- Seamless joint fits and minimal heat distortion

- Optimised nesting techniques

- Reliable batch production and structural assemblies

Automation in Modern Manufacturing

The introduction of CAD software, automated systems, and intelligent monitoring has allowed laser cutting to become more streamlined than ever. Automated systems enable operators to manage multiple machines at once, ensuring that production can progress with minimal interruption.

Integration of new digital technology allows for greater traceability throughout the production process, therefore improving quality assurance and adhering to compliance standards. Delivering absolute transparency ensures that a component is produced with absolute precision and consistency.

The Future of Laser Cutting in Material Manufacturing

The combination of advanced technology, thoughtful sustainable practices, and high precision engineering is all directed towards elevating the future of fabrication. Machine learning and updated technology are all integral to improving how material is profiled, with manufacturers embracing change to remain competitive in the market.

Ultimately, a singular, refined and connected ecosystem under one roof is the most seamless approach to profiling exceptional parts, reducing material waste, and increasing efficiency across manufacturing.

Refine Material Manufacturing with The Laser Cutting Co.

At The Laser Cutting Co., we follow lean manufacturing and PPAP procedures to deliver an exceptional level of quality assurance, execution and service for our clients.

We offer a comprehensive range of fabrication services from large and open section cutting to tube laser cutting, bevel and countersink, and smart design production. For bespoke, quality laser cutting solutions and guidance, get in touch with a member of our expert team today.