Discover High Precision Cutting for Your Supplied Material

At The Laser Cutting Co., we recognise the unique requirements that clients face during their projects, which is why we always strive to make your process even more seamless. We work with free-issue metals, allowing you to supply and work directly from your own materials, while benefiting from advanced laser cutting technology.

Whether it’s steel, aluminium, or specialist alloys, we have the capability to cut your supplied materials to your exact specifications and geometries, achieving clean and accurate edges effortlessly. We encompass a wide range of services all under one roof, including laser, waterjet, flame, and plasma cutting, making sure to conduct a careful assessment for the most suitable cutting type.

Supplying free issue material is ideal for clients who:

- Already hold their own material and want to reduce costs

- Require consistent results across specific grade types

- Have a single trusted partner for all profiling requirements

Why Trust The Laser Cutting Co. for Galvanised Sheet Cutting?

Efficiency

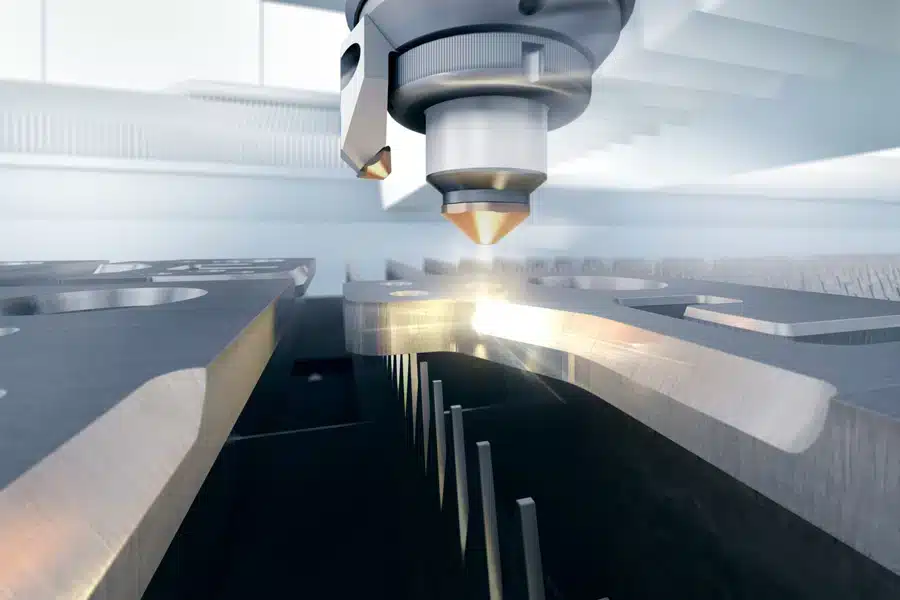

CNC fibre laser cutting machines operate 24 hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on even the largest and most complex projects.

Experience

Over 40 years of laser profiling experience using the latest cutting technologies. Our investments, your benefit

Why Choose Us to Cut Your Free Issue Metal

With over 40 years of experience, we are a trusted leader in UK manufacturing and fabrication. Our advanced fleet of cutting technology allows our professional team to handle challenging material properties and complex designs with ease. No matter the grade or thickness, we are equipped to achieve a flawless finish every time. We can:

- Cut to your exact specification

- Offer full traceability and test certificates

- Deliver precise results without compromising quality

- Provide expert advice on the best cutting method for your project

Our Expert Cutting Services

We accommodate a broad spectrum of materials across several processes each day, tailoring each project for optimal outcome. Integrated alongside our smart design production, we have proven to enhance downstream efficiency, generate cost savings, and reduce the need for secondary processes. If laser cutting isn’t the best option for your material, our team will recommend the most suitable method to deliver the best result.

- Laser Cutting - produces clean, burr-free edges

- Waterjet Cutting - excellent for thicker or heat-sensitive materials

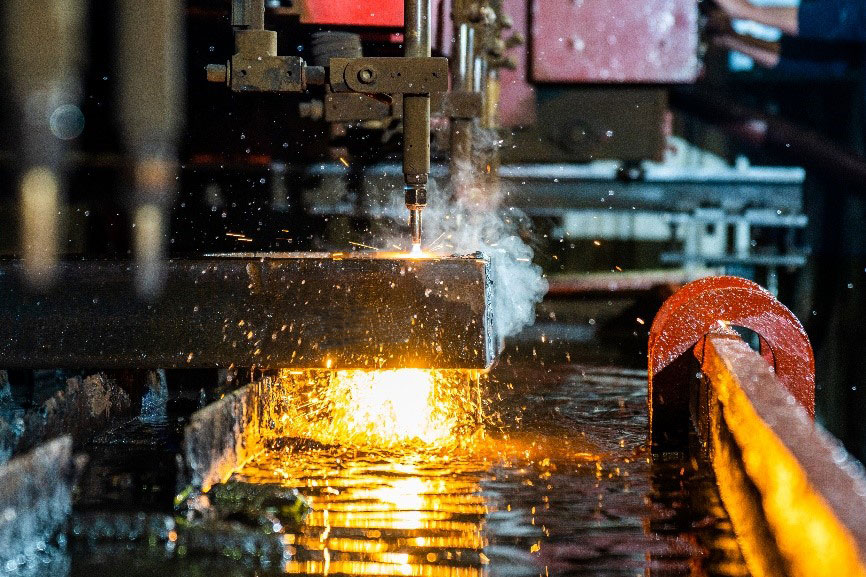

- Flame Cutting - a cost-effective solution for heavy plate solutions

- Plasma Cutting - fast and seamless steel cutting

Alongside our profiling services, we also provide other solutions, such as laser engraving and etching, sheet metal bending, and shot blasting.

Your Free Issue Material Requirements

In order to achieve the highest quality finish, we require your supplied material to meet our specifications, which include:

- The material must be clean

- Be free of rust

- Oil-free

- Flat sheets

- Free from other impurities

By providing sufficiently prepared material, our team can deliver accurate cuts in faster turnaround times.

Material Thicknesses we can accomodate

Material Thickness (mm)

Specialist Waterjet Cutting for Free-Issue Materials

Our waterjet cutting service is perfect for customers supplying non-metallic or specialist materials that are not suitable for laser cutting. Utilising high-pressure water mixed with aggregate medium, we achieve clean, precise edges without heat distortion or stress to the material.

We regularly process free-issue materials such as:

- Plastics and composites (nylon, acrylic, and carbon fibre)

- Stone, marble, and granite (architectural and decorative projects)

- Rubber, foam, and mesh

- Glass and laminates

- Metals that require a cold cutting process

Our fleet of waterjet machines handles substantial thicknesses and complex profiles with ease, maintaining tight tolerances and high-quality finishes across every cut. Our team ensures your supplied material is cut safely, accurately, and with minimal waste.

Laser Bevel and Countersinking

When profiling high tensile materials such as Hardox steel, bevel cutting and countersinking are crucial in delivering clean joints and flush fixings for heavy-duty applications. Establishing recessed areas allows bolts and fasteners to sit at surface level, improving both structural integrity and achieving a polished finish.

Our progressive laser cutting systems can produce highly precise bevels and countersinks as a standard procedure within the fabrication process. This eliminates the need for secondary machining, effectively reducing lead times and ensuring each Hardox component is installation-ready to exceptional standards.

Quality Assurance

The Laser Cutting Co.’s Quality Promise

At The Laser Cutting Co., we work and adhere to strict quality standards, supplying certificates on request to support traceability and compliance. We can also rapidly procure high-quality material from a CE-approved mill, or beyond, meeting BS EN 1090-1 standards. We are also committed to our strong, sustainable ethos, operating from renewable energy and low-emission processes to effectively manage our carbon footprint.