Key Takeaways

- A single laser cutting supplier improves consistency and quality, reducing rework for misaligned and poorly cut parts.

- A sole supplier improves purchasing power, which lowers overall unit costs and improves budget constraints.

- One supply chain provides predictable lead times and full accountability if there are errors during the process.

In metal fabrication, it’s not uncommon for companies to seek out ways in which expenses can be driven down further. Frequently, businesses will seek out multiple suppliers, with the hope of reducing costs and expediting delivery times. However, this is usually not the case and can be quite the opposite. In many circumstances, this can cause a rise in spending, inconsistent quality, long processing times and extra admin burden. This guide delves into why partnering with a single supplier for laser cutting needs is usually the most economical option.

Seamless and Reliable Results

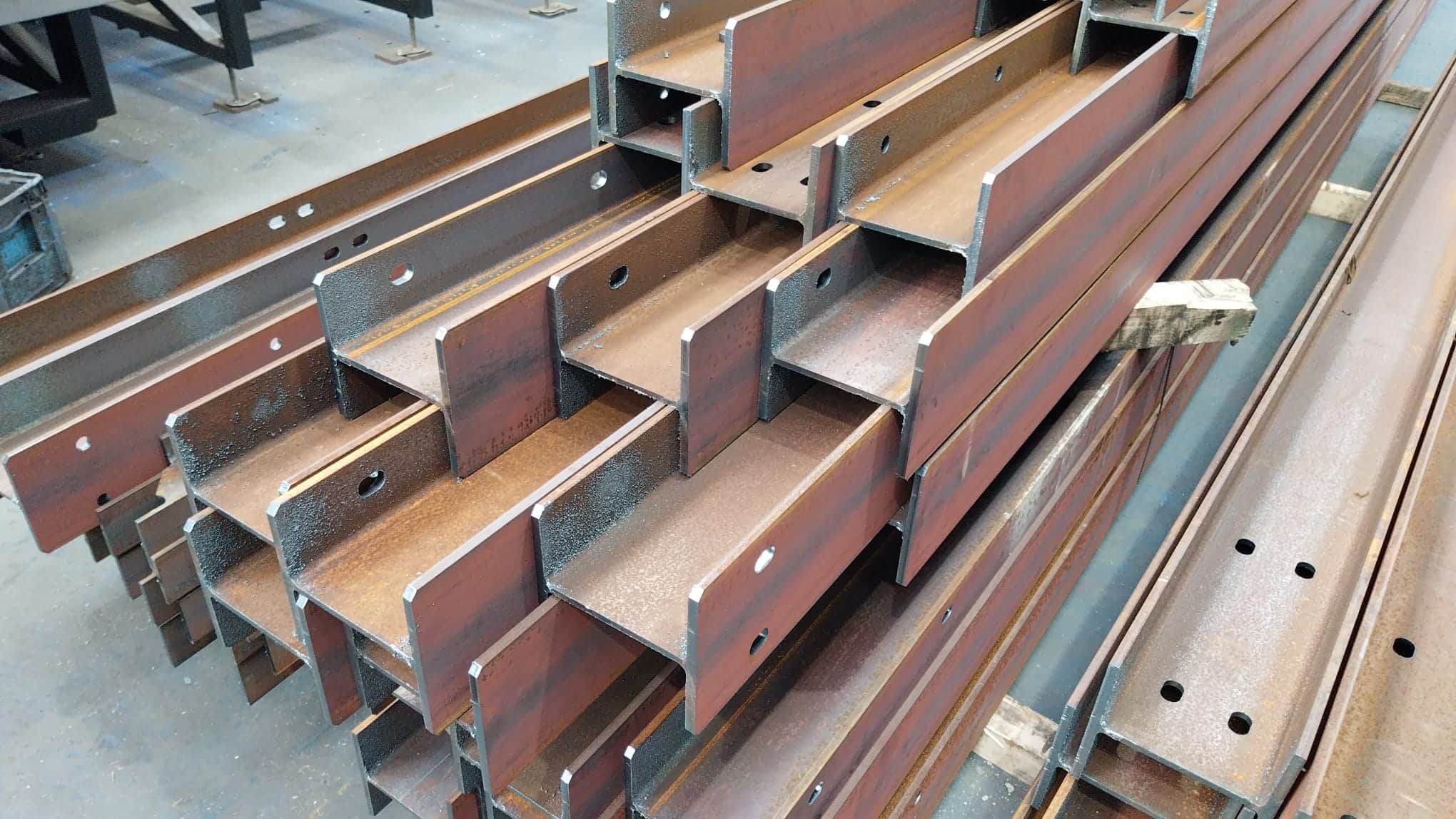

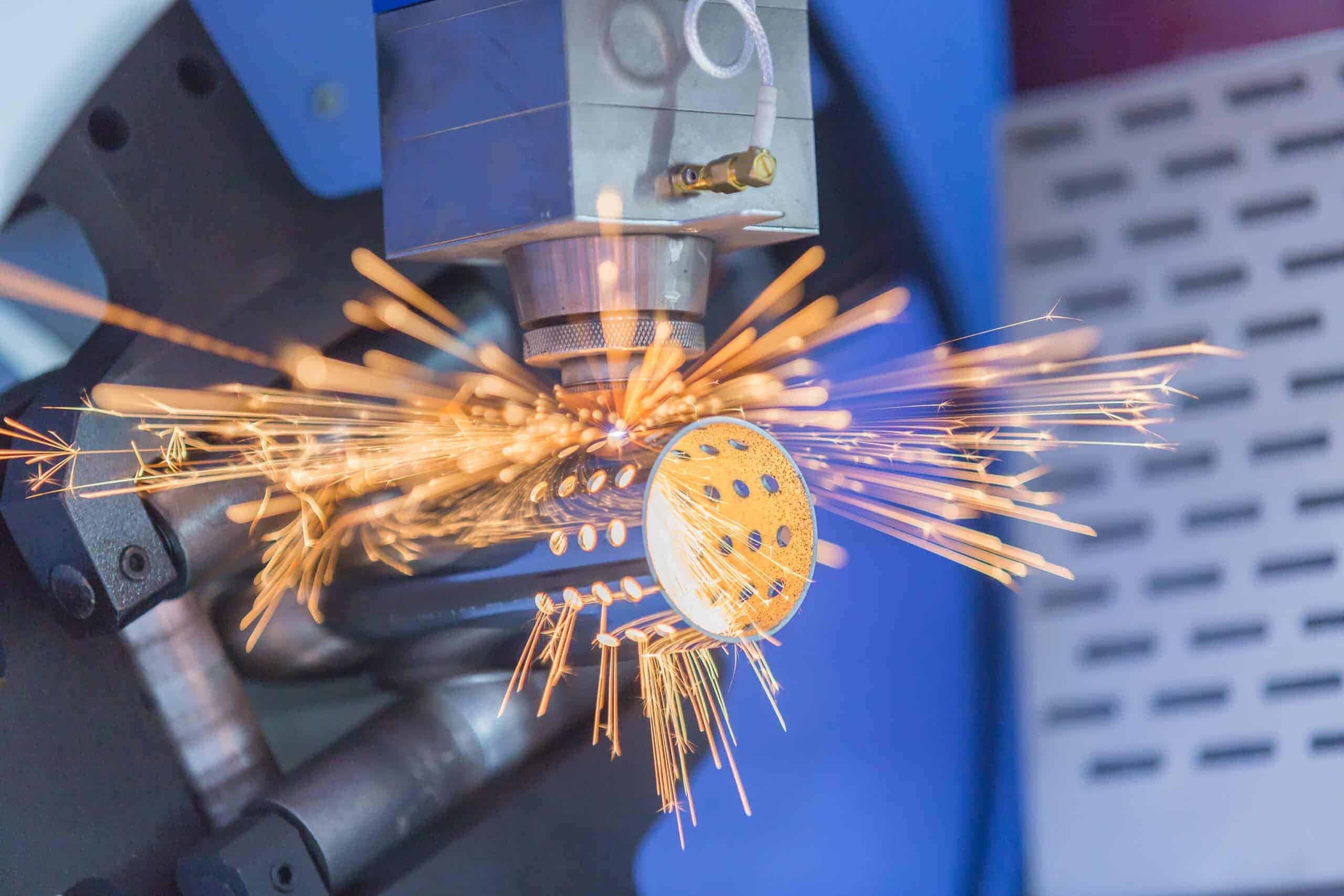

The machinery and software used across laser cutting suppliers often differ, and this goes for the level of expertise and quality assurance that is carried out. Although deemed as minor circumstances, this can create great variability in each product delivered. This is not always noticeable until the project is complete, which leaves behind misaligned parts, additional rework, and makes assembly incredibly difficult.

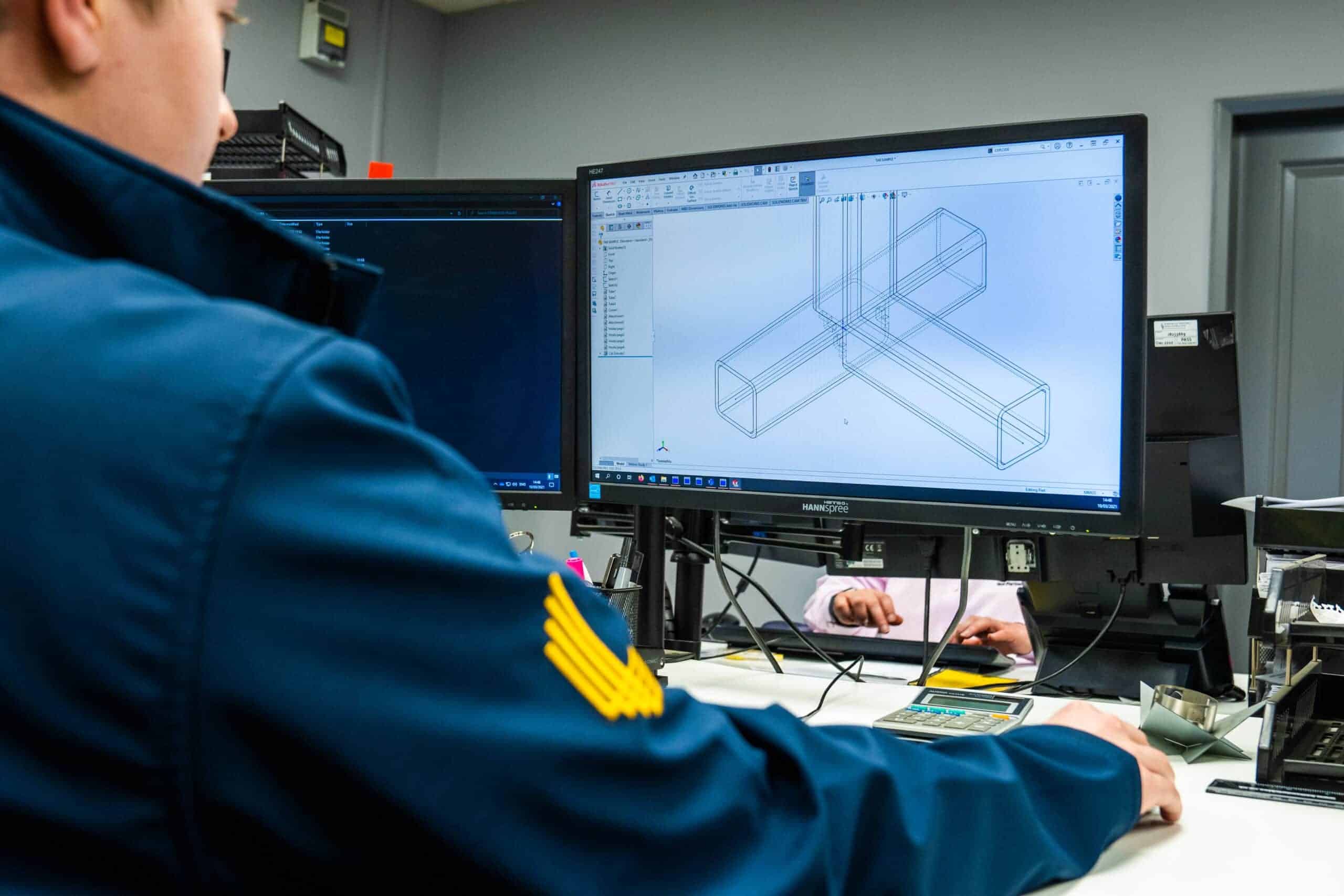

Opting for a singular and reputable manufacturer virtually eliminates this issue as the parts are cut to an even standard and under the same procedures. When partnered with techniques such as nesting and advanced lasers, waste is minimised, and an overall higher level of output is achieved.

Reducing Administrative Duties

Handling suppliers, amongst a range of other duties, frequently takes up significant time. Every supplier needs onboarding, price quotes, purchase orders, production monitoring, delivery planning and billing. When this is replicated across companies, it unnecessarily burdens administrative efforts.

A single supplier negates this entire process, which allows businesses to stay in touch with one point of contact, rather than several, and manage stress or workload more easily. Project managers can then function more efficiently with less miscommunication, fewer order errors, and a lower mass of paperwork in general.

Improves Purchasing Power

Contrary to belief, leveraging rates between suppliers does not necessarily reduce the amount spent on a project. In actuality, it can cause the budget to go beyond expected forecasts as it raises the expense per unit manufactured and reduces purchasing power.

Investing in a large-scale project helps a manufacturer drive down expenses and generate overall cost savings. This is also beneficial in letting your laser cutting supplier predict demands and fluctuations, and place your project as a greater priority compared to several smaller ones.

Predictable Lead Times

Managing delivery timelines among manufacturers can be difficult. Every supplier has processes, capabilities and schedules which may result in inconsistent timing. A minor delay from a supplier can stall the whole project.

Placing a project order through one supplier can streamline the process and make it far simpler and efficient. Businesses can stay on track with updated timelines and ongoing communication, which helps stick to set deadlines.

Eliminate Quality Discrepancies

The material used within a project is always an important process, which helps to establish success from the very start. Different suppliers are likely to procure material from various sources, which can have a very wide range in terms of quality, grades, and availability. Even a difference in the materials’ thickness or coating can drastically alter the final result.

With just one supplier, there is greater control over the material used, which also offers greater insight as to how it will perform when cut. A quality laser cutting company will be able to demonstrate and explain the most suitable material for a project, while procuring enough stock to last throughout production.

Eliminate Quality Discrepancies

The material used within a project is always an important process, which helps to establish success from the very start. Different suppliers are likely to procure material from various sources, which can have a very wide range in terms of quality, grades, and availability. Even a difference in the materials’ thickness or coating can drastically alter the final result.

With just one supplier, there is greater control over the material used, which also offers greater insight as to how it will perform when cut. A quality laser cutting company will be able to demonstrate and explain the most suitable material for a project, while procuring enough stock to last throughout production.

Eliminate Quality Discrepancies

The material used within a project is always an important process, which helps to establish success from the very start. Different suppliers are likely to procure material from various sources, which can have a very wide range in terms of quality, grades, and availability. Even a difference in the materials’ thickness or coating can drastically alter the final result.

With just one supplier, there is greater control over the material used, which also offers greater insight as to how it will perform when cut. A quality laser cutting company will be able to demonstrate and explain the most suitable material for a project, while procuring enough stock to last throughout production.

Streamline Your Projects with The Laser Cutting Co.

At The Laser Cutting Co., we make projects effortless with our full turnkey approach to metal profiling. From smart design production through to final powder coatings and engraving, we collaborate with clients and remain communicative, helpful, and entirely reliable.

We offer a comprehensive range of metal fabrication services from large and open section cutting to tube laser cutting, bevel and countersink. For bespoke, quality laser cutting solutions and guidance, get in touch with a member of our expert team today.