Advanced Laser Cutting for Pioneering Industries

At The Laser Cutting Co., we work alongside engineering and fabrication industries to deliver high-grade components that perform flawlessly. We understand that each project is different, which is why we are proud to showcase the flexibility across our cutting methods to find bespoke options for your business.

Our team can source and cut materials across any grade, thickness, and property type, presenting you with a range of profiling options that meet all industry requirements. We always work with care, offering clients a comprehensive and rapid service, protecting material integrity to a high standard and avoiding costly reworks from the very start.

Whether you are looking for structural parts, decorative components, large-scale production, or a one-off prototype, we have the modern tech and knowledge to support your project, from start to finish.

Seamless Profiling in Engineering and Fabrication

At The Laser Cutting Co., we support businesses in industries where high quality and repeatability are non-negotiable. Which is why we take great care in our services and quality assurance to offer the very best in the market for our clients.

Our team can rapidly source a vast catalogue of materials for your needs, easily meeting the requirements expected for structural components or intricate parts. We can guide you through the journey, whether it’s smart design production, laser cutting, sheet metal bending, or more. The Laser Cutting Co. is your reliable partner for all engineering and fabrication needs.

Applications of Engineering & Fabrication Laser Cutting

Laser cutting is a modular and progressive technology, transforming both engineering and fabrication sectors with high-quality profiling solutions. Typical applications include:

Engineering firms and equipment manufacturers, who require accurate and reliable metal components.

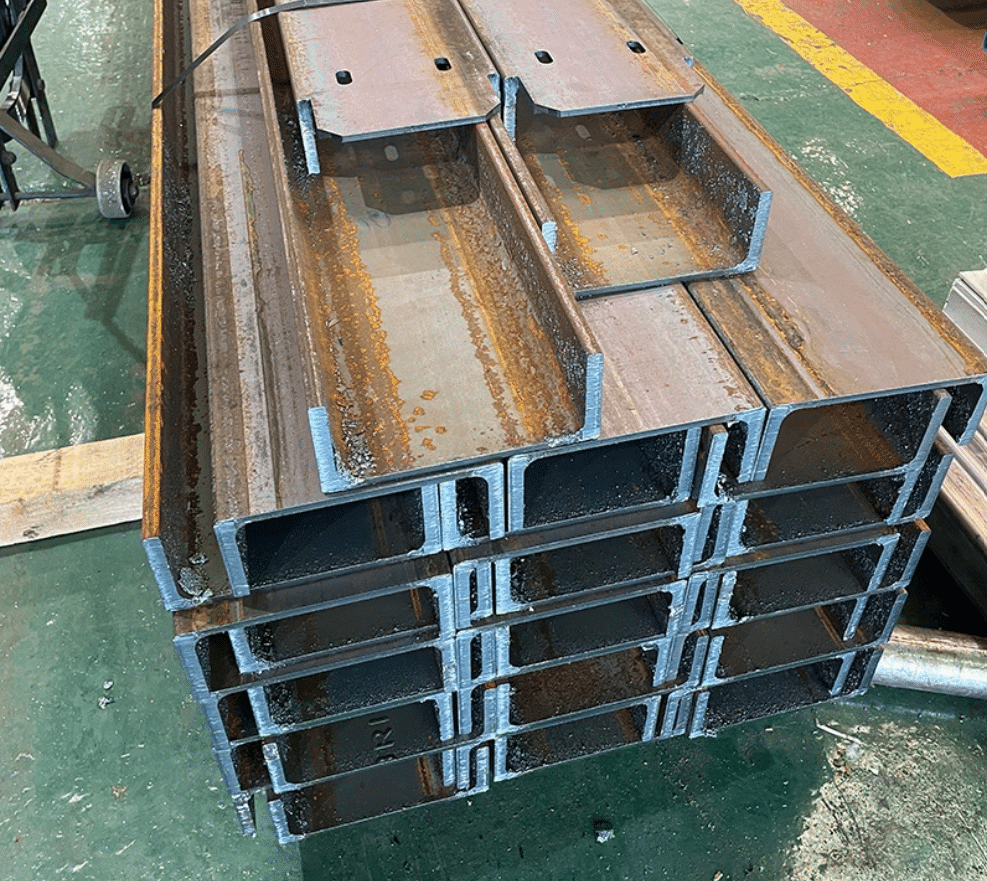

Fabricators and structural steelwork businesses that procure weld-prepped profiles, beams or sections.

Complex and intricate manufacturing needs, which benefit from high precision, tight tolerances, and minimised waste from non-contact processes.

Prototype and batch producers who need flexibility, fast turnaround, and support during the initial product design phase.

Businesses aiming to reduce post-processing, such as welding, manual drilling or cutting, tapping or forming.

Materials and Parts We Work With in Engineering and Fabrication

Laser cutting is constantly evolving and has quickly become a dependable solution in modern sectors, such as:

- Automotive & Aerospace

- Medical Devices

- Architecture & Signage

- Electronics

- Agriculture

- Construction

- Energy Sector

Our Material Cutting Services and Capabilities

We offer solutions that are perfect for small and large engineering and fabrication projects.

Sheet Laser Cutting

- We process sheet sizes up to 6510mm x 2600mm, with the ability to process larger sizes where required. This option is most suitable for mild steel, stainless steel, and aluminium, but we can also profile other metals.

- Thickness profiling ranges up to 50 mm, depending on the material type.

- Suitable for intricate profiles, complex contours and benefits from nesting techniques for highly-efficient material use.

Open Section Laser Cutting

- Our multi-axis tube laser is excellent for round, rectangular, and complex section cutting.

- We can cut large and open sections on profiles such as PFC, RSA angle, and universal beams to accurate lengths, mitres, bevels, and specialised cutting needs.

- Our team deliver high precision cuts that minimise downstream welding, trimming, and fabrication work.

Bevel & Countersink

- Bevels can be cut at 45° on both inner and outer contours, eliminating the need for manual weld preparation.

- We can produce countersinks of any size in the cutting process, ready for screw fixings and fastening requirements.

- Removes the need for grinding, chamfering, or manual prep, streamlining your welding and assembly workflow.

Flowdrilling & Tapping

- We integrate flow-drill and tapping services during laser profiling, creating high-strength threaded holes directly in sheets or tubes.

- Eliminates the need for additional fasteners or welded inserts, which cuts assembly time, improves strength, and reduces labour.

Sheet Metal Bending

- Our press brake forming service helps to assist in bending metals that deliver a finished, shaped part that’s ready to use.

- Suitable for complex and heavy-duty projects, facilitating quick delivery of ready-to-use fabricated assemblies.

Smart Design Production

- Our in-house team reviews client drawings and adjusts designs to optimise materials ready for laser cutting, reducing them down to singular, self-jigging parts.

- Creates reduced material consumption, rapid assembly, and lower labour costs overall.

- Valuable for prototyping, batch production, and complex fabrication within tight tolerances.

Materials and Parts We Work With in Engineering and Fabrication

We profile and understand a wide range of engineering and fabrication needs, which include:

- Mild and carbon steel, stainless steel, aluminium, copper, brass, bronze, titanium, and more.

- Sheets, plates, tubes, and structural profiles, simplifying the production of light brackets to heavy-duty structural components.

- Processes can be scaled depending on project size and requirements, from individual prototypes to high-volume production.

Quality Assurance

The Laser Cutting Co.’s Quality Promise

At The Laser Cutting Co., we work and adhere to strict quality standards, supplying certificates on request to support traceability and compliance. We can also rapidly procure high-quality material from a CE-approved mill, or beyond, meeting BS EN 1090-1 standards. We are also committed to our strong, sustainable ethos, operating from renewable energy and low-emission processes to effectively manage our carbon footprint.