Discover Corten Steel’s Exceptional Quality

Corten steel, also referred to as Cor-Ten or weathering steel, is a distinctive material that is often remarked for its ability to form its own protective layer. This process creates a faux rust patina, offering a striking visual appeal when exposed to weather elements. Due to this, Corten steel is often utilised in architectural, design, and aesthetic-led projects.

Corten steel is a copper-chromium alloy that establishes a stable oxide layer, giving it its characteristic orange quality and the unique ability to self-heal if penetrated. This helps deter extensive corrosion occurring over time, resulting in minimal maintenance and the need for additional protective coatings.

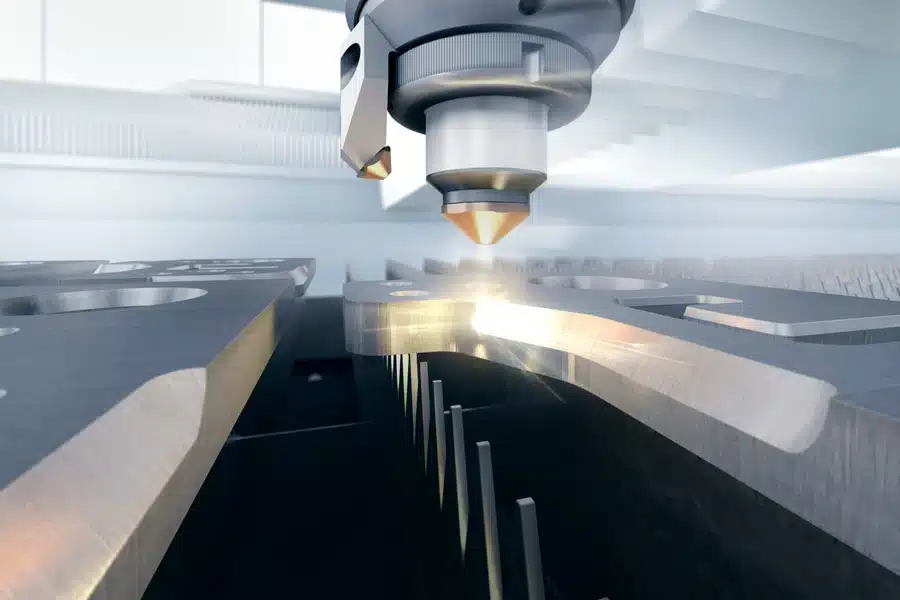

At The Laser Cutting Co., we have a wealth of experience delivering exceptional laser cutting across a range of commercial and industrial applications, achieving high-grade cut quality and efficiency. Our next-gen fleet of flatbed lasers is accelerated by our smart design production services, including bevel and countersink, sheet metal cutting, flow drilling and tapping.

Why Trust The Laser Cutting Co. for Galvanised Sheet Cutting?

Efficiency

CNC fibre laser cutting machines operate 24 hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on even the largest and most complex projects.

Experience

Over 40 years of laser profiling experience using the latest cutting technologies. Our investments, your benefit

Remarkable Strength and Visual Appeal

Corten steel is highly valued due to its organic and rich colour appearance. As the metal is exposed to wet and dry conditions, the patina layer continues to regenerate, with an initial developing period between 6 to 12 months, continuing to deepen over time.

This characteristic makes Corten steel particularly suited to outdoor applications, withstanding exposure to varying climates while still maintaining structural integrity for decades. Not only does it stand out for its aesthetic quality, but it also features incredible tensile strength, which makes it a durable material for heavy-duty and load-bearing applications.

Our expert team at The Laser Cutting Co. understands the unique requirements of working with Corten steel. Our laser cutting beds allow us to process materials within fine tolerances, delivering clean, burr free edges and high-grade finishes across complex geometries.

Corten Steel Applications

Corten steel is a versatile material, applicable to an extensive range of applications, including but not limited to:

- Architectural design and wall cladding

- Garden features such as planters and screens

- Sculptures and art installations

- Fencing, retaining walls, and bridges

- Signage and structures

Corten Steel Grades

Cor-Ten A: Lighter in weight, this grade is suitable for decorative and non-structural applications.

Cor-Ten B: A higher strength grade that is utilised in load-bearing applications, such as bridges and structures.

We can laser-cut sheets in numerous grades and depths to meet your expected project requirements.

Sheet Metal Laser Cutting Thicknesses

Material Thickness (mm)

What are the Benefits of Laser Cutting?

Laser cutting provides consistent and quality Corten steel manufacturing within the metal profiling sector. Some advantages of laser cutting include:

Precision & Accuracy

Laser cutting achieves highly precise cuts, often working within fine tolerances of +/- 0.1mm.

Adaptable

Lasers can process complex shapes and cut thick sheets of Corten steel with ease, maintaining consistent high-quality throughput.

Clean Cuts

Our highly powered laser beams can deliver smooth and burr free edges without secondary finishes, maintaining structural integrity.

Speed & Efficiency

Laser cutting expedites lead times and enhances downstream efficiency through automation and smart design software.

Reduces Waste

Through nesting techniques and highly accurate results, laser cutting effectively minimises waste across projects.

Cost-Effectiveness

Laser cutting utilises material incredibly well through narrow kerf and nesting, delivering greater cost efficiency.

In-House Bending and Pressing Solutions

At The Laser Cutting Co., we provide in-house bending and pressing capabilities alongside our advanced laser cutting solutions. This allows us to form metals such as Corten steel into custom components, which include cladding, structural parts, and ornamental features with accuracy and quality craftsmanship.

Our team guarantees clean, consistent results that preserve both the durability and aesthetic quality of Corten steel. We provide 24/7 production with full in-house services, offering fast, reliable results across all projects of any scale or complexity.

Laser Bevel and Countersinking

Bevel and countersinking is often utilised when working with Corten steel, delivering architectural panels and features that require clean and flush fixings. Countersinking ensures screws and bolts sit at the surface level, preserving a seamless appearance.

Our advanced laser systems can carry out both bevel cuts and countersinks with high precision, reducing the need for secondary processing and ensuring components are ready for installation straight from production.