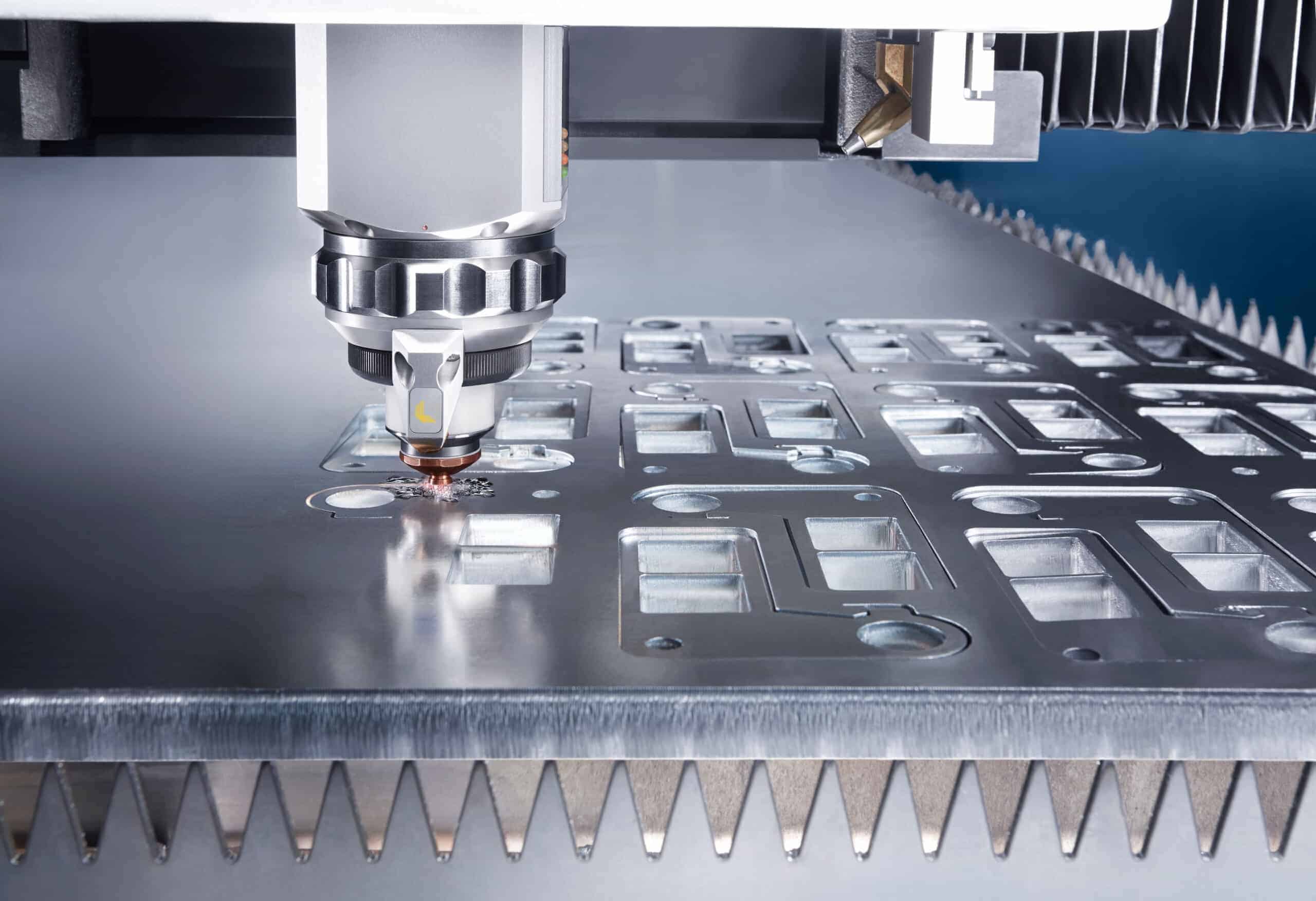

Professional Sheet Metal Laser Cutting Services

Precision sheet metal laser cutting with rapid lead times from our high capacity, Sheffield-based production facility.

24-hour lights-out manufacturing across our comprehensive suite of laser cutting machines ensures even the largest projects receive a fast turnaround. Complemented by an in-house design team and end-to-end processing services, our sheet metal laser cutting is hard to beat.

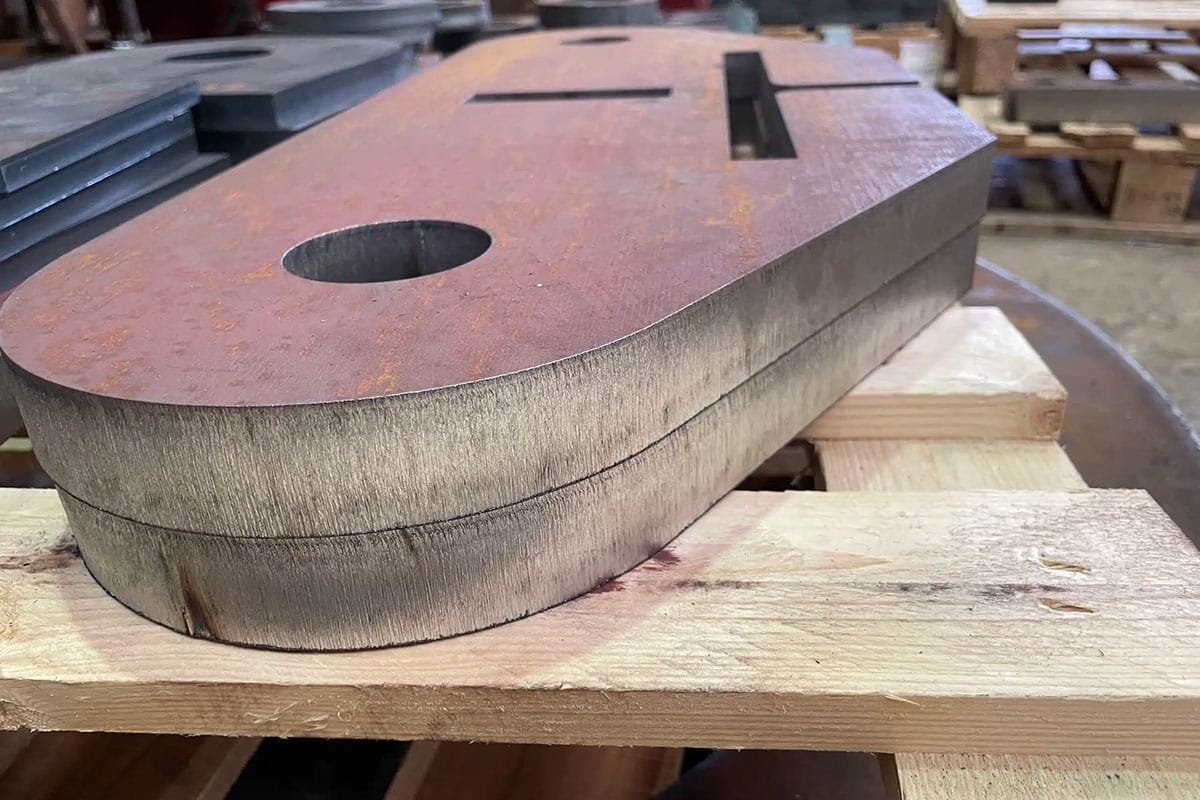

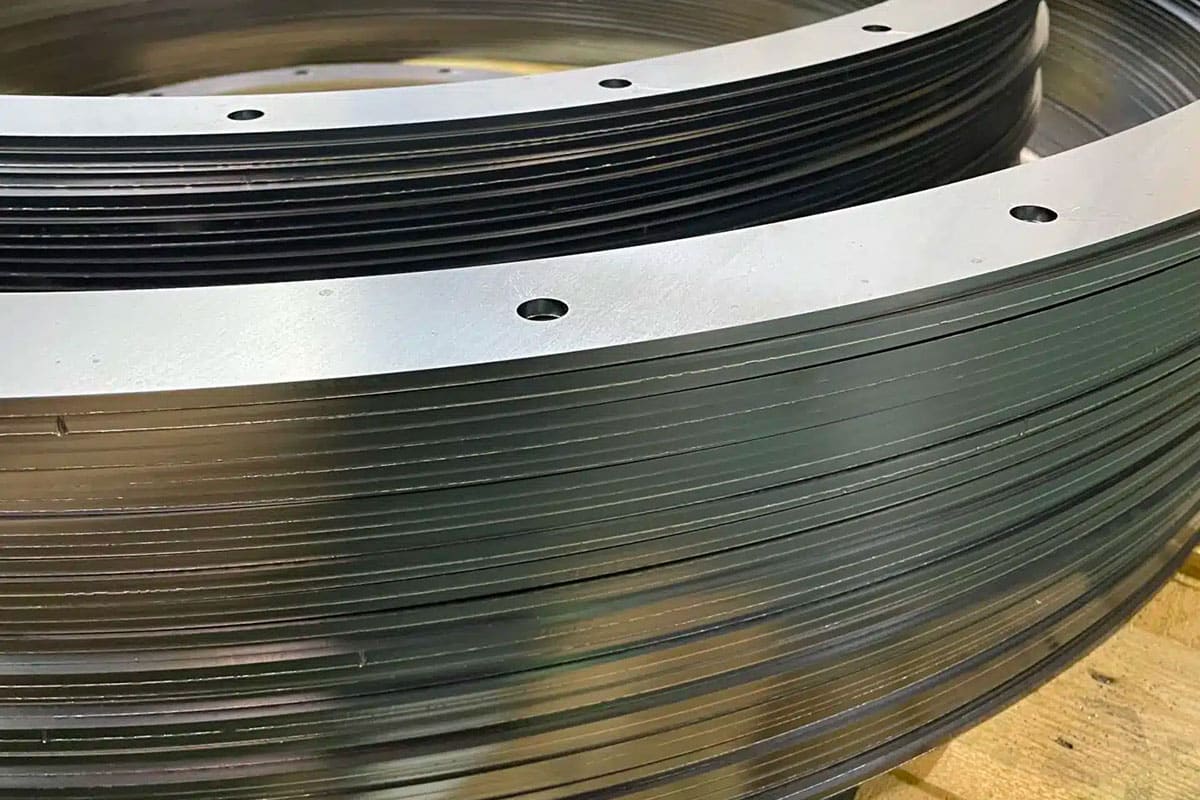

The Laser Cutting Co. have two dedicated flatbed laser cutting machines handling sheet metal sizes up to 2000 x 4000mm and up to 50mm thick, depending on the material type. Our 6kw and 10kw solid-state fibre lasers deliver exceptional quality cutting finish, reducing pre-weld preparation. We have access to a further 6 cutting machines at our Sheffield-based sister site including the UK’s first 15kw laser source on a 6000mm x 2500mm cutting bed.

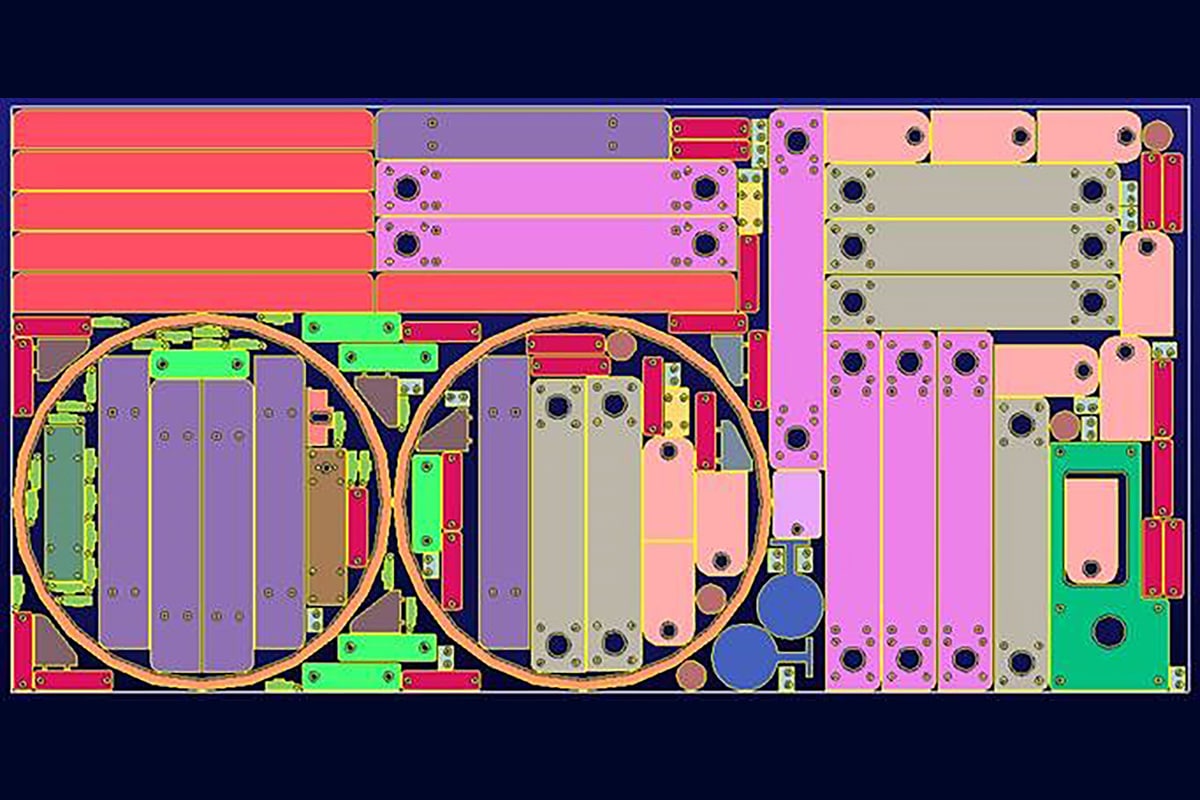

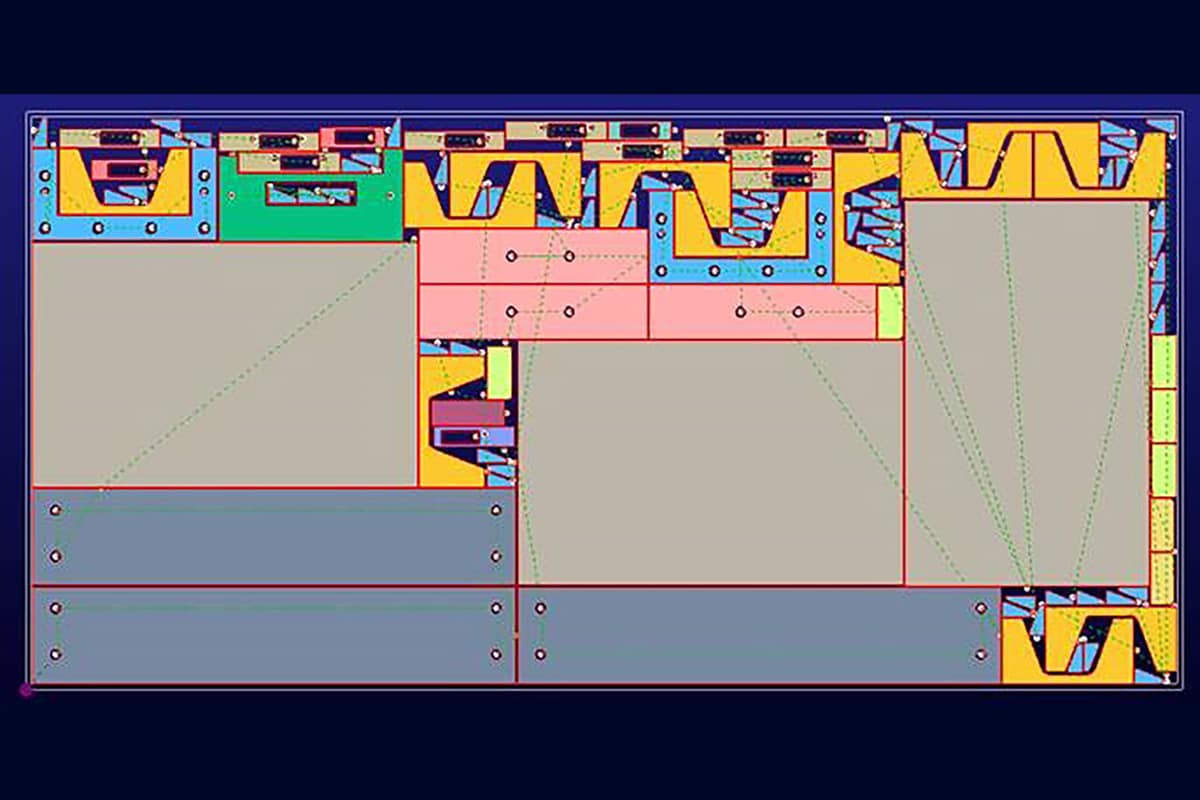

CNC laser cutting technology guarantees absolute accuracy, and intricate cutting and fine contouring are achievable across a range of metals, including thin and thick mild steel. Our laser cutting services can help eliminate additional process steps with the ability to produce chamfers and countersinks in a single pass. Tighter nesting ensures that we can deliver a highly cost-effective laser cutting sheet metal service.

Why Choose The Laser Cutting Co. for Sheet Metal Laser Cutting?

Efficiency

CNC fibre laser cutting machines operate 24 hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years laser profiling experience using the latest cutting technologies. Our investments, your benefit.

Benefits of The Laser Cutting Co.’s Sheet Metal Laser Cutting Services

Up to 2.5m x 6m sheet metal

Up to 50mm thick

+-0.25mm cutting tolerance

Rapid lead times

Reliable service

Certification and traceability

What Are the Benefits of Flatbed Laser Cutting?

When it comes to precision sheet metal laser cutting, our flatbed laser cutting services at The Laser Cutting Co. are a cut above the rest. Equipped with cutting-edge technology and bolstered by over 40 years of laser profiling expertise, our flatbed laser cutting machines stand ready to tackle projects of all sizes with unparalleled efficiency and quality. Some of the many benefits of flatbed laser cutting include…

Exceptional Precision

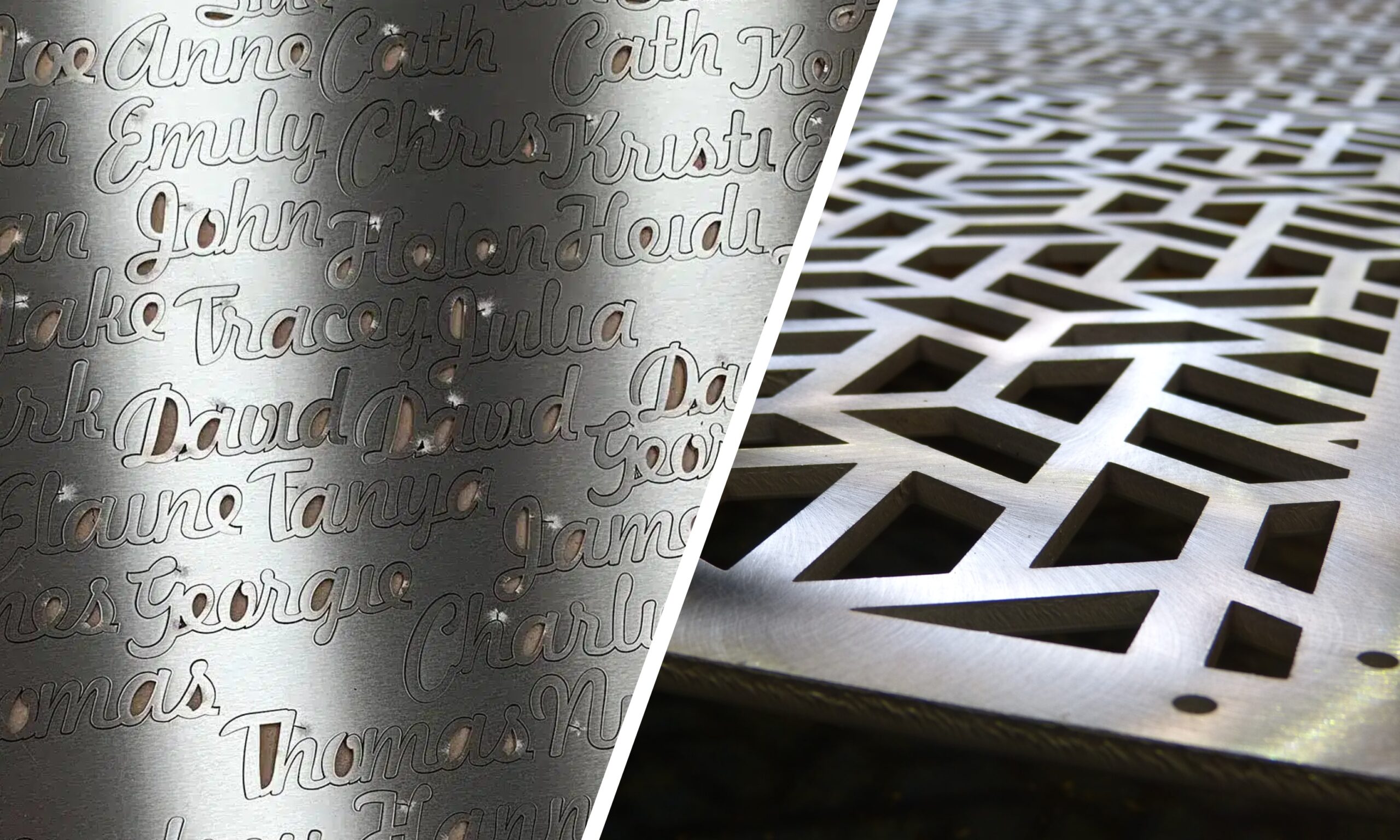

Our flatbed sheet laser cutting boasts unparalleled precision, thanks to advanced CNC technology that ensures absolute accuracy in every cut. This precision is vital for intricate designs and tight tolerances, enabling consistent quality and precise specifications

Versatility

Flatbed sheet laser cutting is highly versatile, handling a wide range of materials and thicknesses effortlessly. From thin sheets to thick plates, and ferrous to non-ferrous metals, our machines can accommodate diverse needs across industries like automotive, aerospace, and electronics

Efficiency

With 24-hour lights-out manufacturing and rapid lead times, flatbed laser cutting ensures swift turnaround for even the most demanding projects. Automation minimises downtime and maximises productivity, meeting tight deadlines without compromising quality.

Cost-Effectiveness

Flatbed laser cutting offers cost-effective solutions by eliminating multiple process steps and reducing material waste. Tighter nesting enhances cost savings by maximising material utilisation, providing excellent value for investment.

Superior Quality

Our high-power solid-state fibre lasers deliver clean, precise cuts with minimal heat-affected zones, ensuring superior edge quality and minimal distortion. This quality enhances aesthetics and improves functionality and performance.

Streamlined Workflow

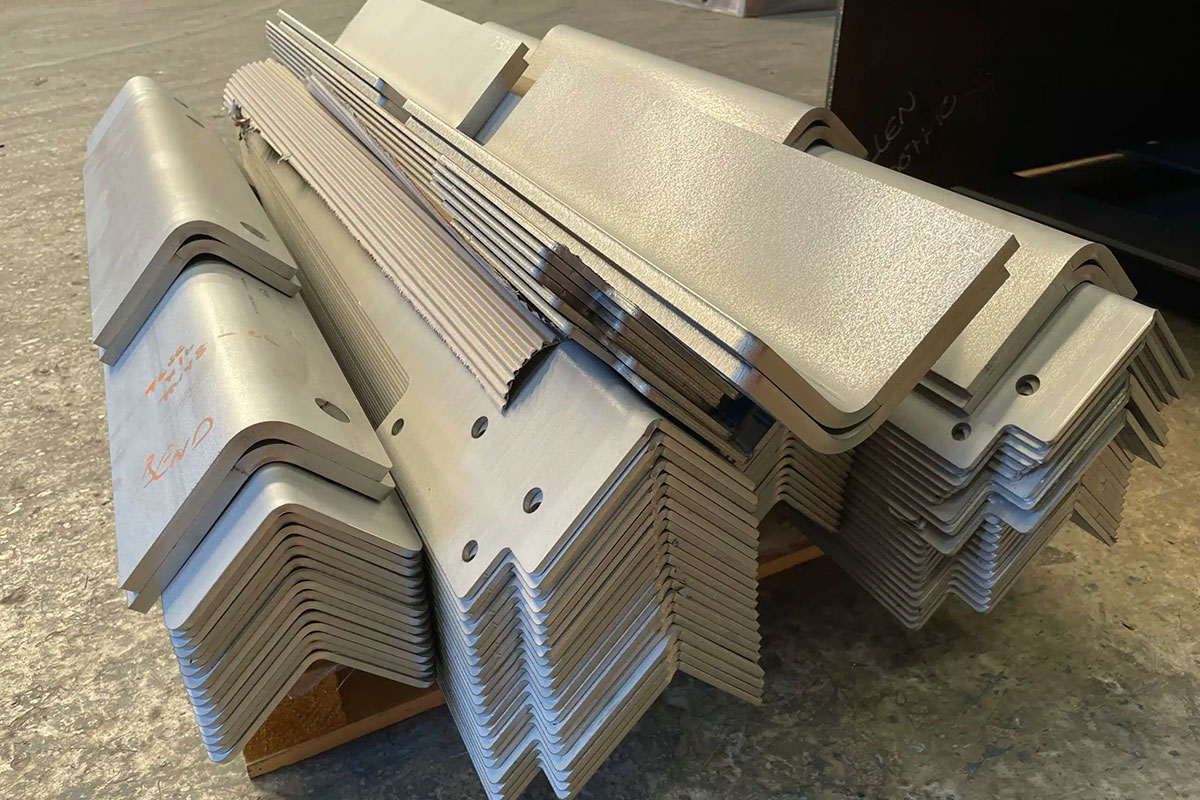

Flatbed sheet laser cutting simplifies workflow by producing complex shapes and contours in a single pass, eliminating the need for secondary operations like machining. This saves time and enhances overall efficiency and productivity.

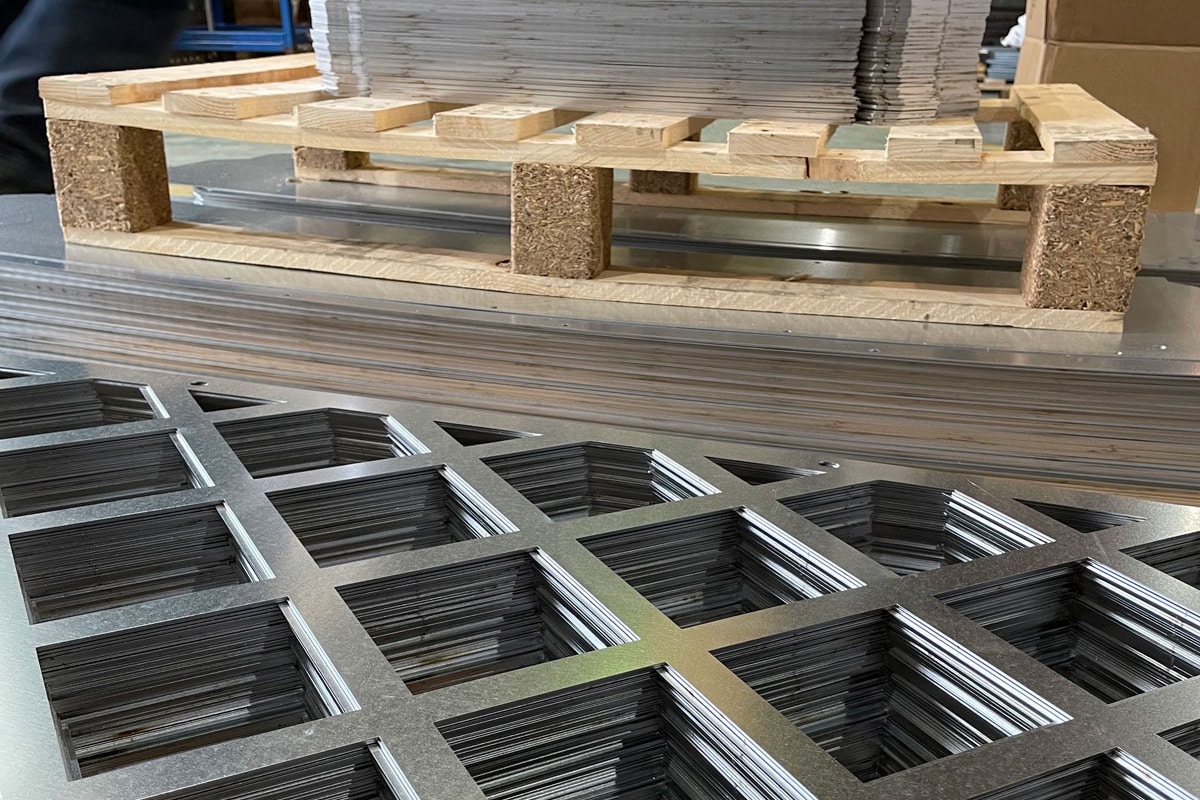

Unrivalled Sheet Metal Laser Cut Part Quality

We invest in the latest laser cutting technology, so you don’t have to. Our flatbed laser cutting machines deliver the highest part quality. Laser cut parts are easy to remove, limiting damage to parts and speeding up downstream processes.

An impressive range of ferrous and non-ferrous metals can be cut without reflections, including film-coated sheet metal. Active cooling ensures complex geometries and tighter nesting are possible, even in mild steel, with fast processing times.

Unrivalled quality ensures our laser cutting processes are highly efficient. This means we consistently offer highly competitive sheet metal laser cutting prices for our customers. Significantly reduced waste results in lower material costs for our customers.

Sheet Metal Laser Cutting Thicknesses

Material Thickness (mm)

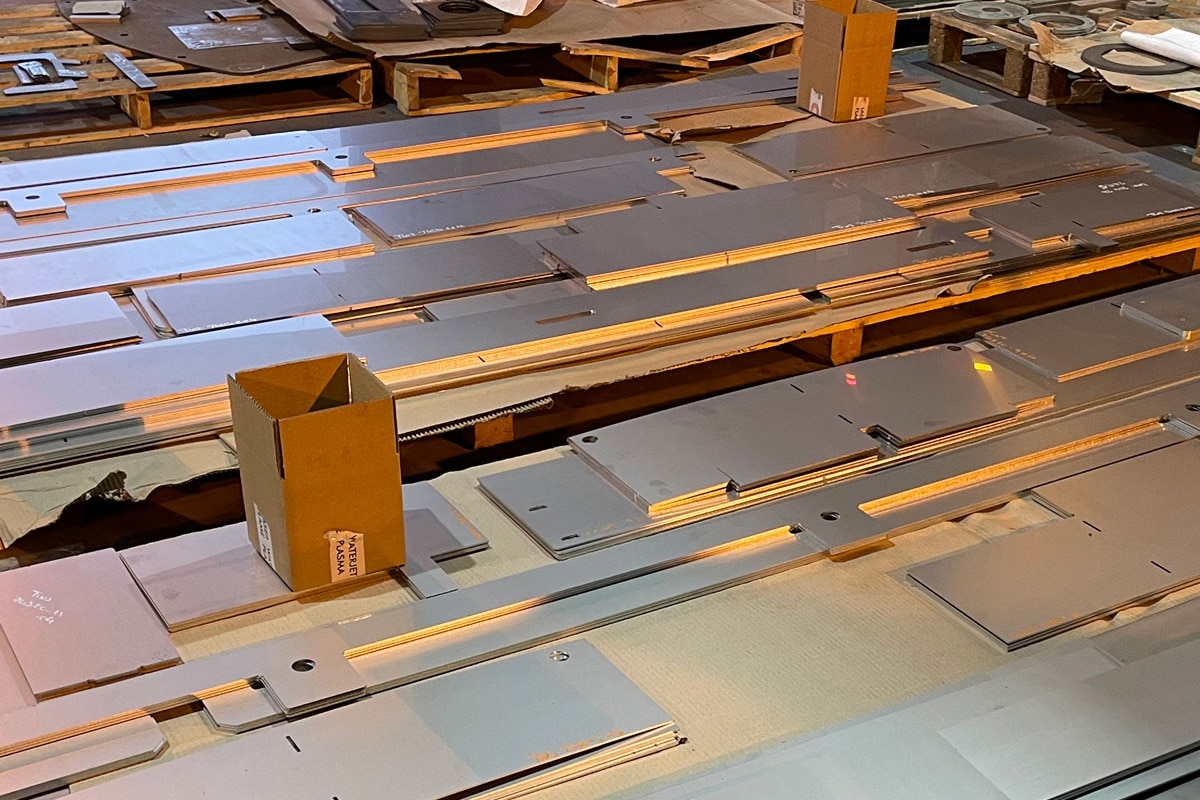

Sheet Metal Laser Cutting From Drawing to Delivery

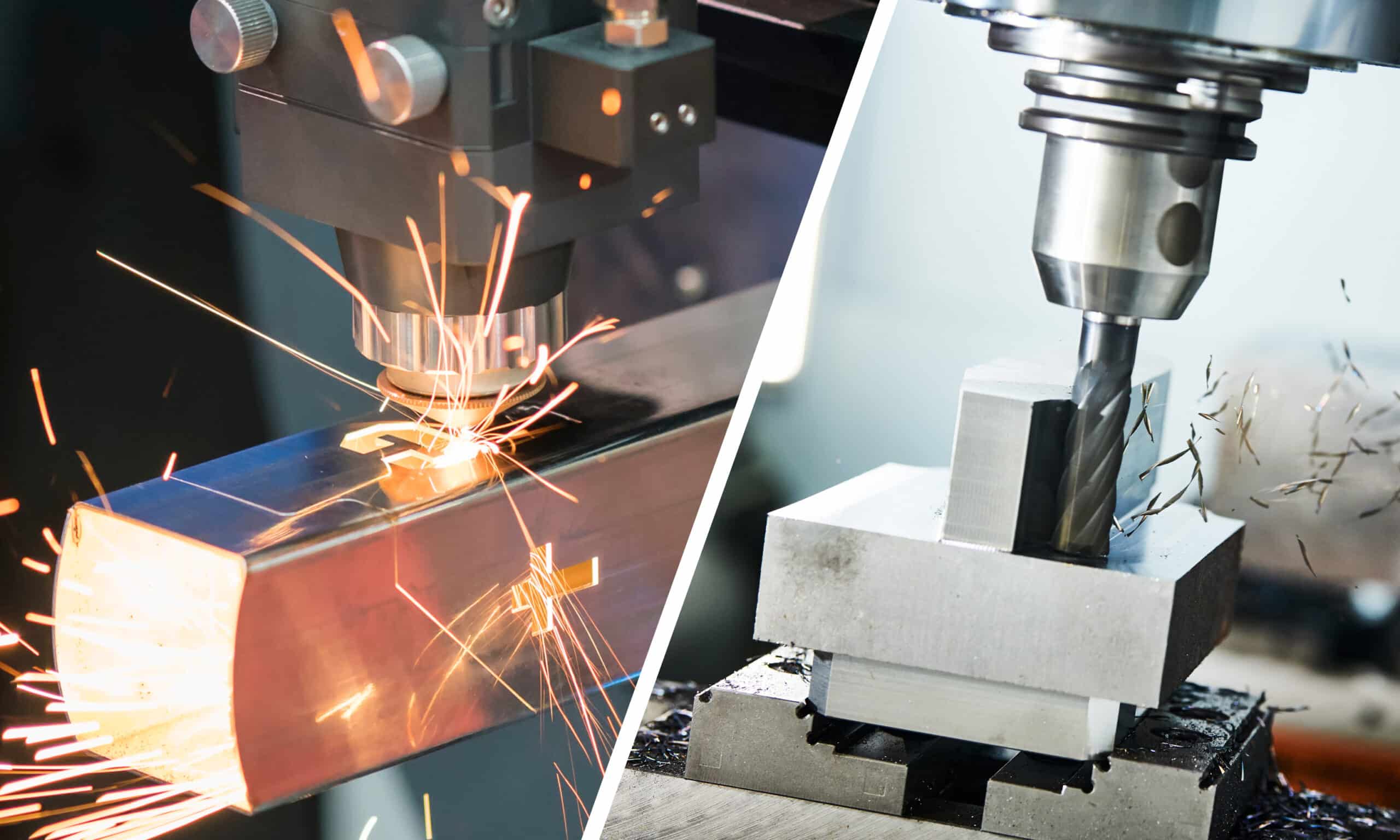

The Laser Cutting Co. offers a range of complementary services beyond our large laser cutting capacity. Under one roof we have an impressive combination of different cutting technologies. Our cutting technologies include modern fibre lasers, traditional CO2 lasers, waterjet cutting, and flame cutting.

We provide a metal profiling service tailored to your requirements. Regardless of the size or complexity of your project, our sheet metal laser cutting service will support your request. For customers operating within supply chains demanding stringent part tracking, all the materials we cut can be supplied with certification and full traceability, in line with our ISO9001 and BSEN 1090 Execution Class 4 accreditations (both CE and UKCA achieved).

From drawing to delivery, The Laser Cutting Co. remove complexity and increase quality. Our customers benefit from cost savings and efficient downstream production processes.

Quality Assurance

The Laser Cutting Co.’s Quality Promise

The highest possible quality standards with the after sales support to match

Our Factory Production Controls are in accordance with legally enforceable construction product regulation BS EN 1090 – Level 3, allowing intricate cutting of construction regulation profiles

Certified to BS EN ISO 9001:2015 for all profiling requirements

Sheet Metal Laser Cutting FAQ's

What is sheet metal laser cutting?

Sheet metal laser cutting is a precise and efficient industrial process that uses a high-powered laser beam to cut intricate shapes, designs, or patterns from flat sheets of metal. The laser beam melts, burns, or vaporizes the material, creating accurate cuts with minimal heat-affected zones.

What types of metals can be laser cut?

Laser cutting is an extremely versatile method of processing a wide range of sheet metals, some of which include:

- Stainless steel

- Mild/carbon steel

- Aluminium

- Titanium

- Brass

- Copper

- Bronze

- Alloys

The suitability of metal for laser cutting depends on factors like thickness, reflectivity, and thermal conductivity. For more information, contact The Laser Cutting Co. today.

How does sheet metal laser cutting work?

Laser cutting machines direct a focused laser beam onto the metal surface. The intense heat from the laser melts or vaporizes the material along the designated cutting path. Simultaneously, a gas jet blows away the molten metal, resulting in a precise cut. Computer numerical control (CNC) programming guides the laser’s movement to create intricate shapes.

What are the advantages of sheet metal laser cutting?

Sheet metal laser cutting offers high precision, intricate detailing, minimal material wastage, reduced tool wear, fast production times, and the ability to cut complex shapes without the need for specialised tooling.

What sheet thicknesses can be laser cut?

At The Laser Cutting Co., we can cut metal sheet thicknesses from 10mm up to 50mm thick, depending upon the sheet metal chosen.

For expert sheet metal laser cutting services, contact The Laser Cutting Co. today.

What industries commonly use sheet metal laser cutting?

Sheet metal laser cutting is utilised across an expansive range of industries, including automotive manufacturing, electronics, architecture, signage, medical device production, consumer goods manufacturing, and much more.

Can laser cutting be used for etchings and engravings on sheet metal?

Yes, laser cutting machines can be used for engraving and etching operations on sheet metal surfaces, allowing for detailed designs, serial codes, batch numbers, QR codes, and logos.

For bespoke laser etching and engraving services, contact The Laser Cutting Co. today.

What is the cost of sheet metal laser cutting?

The cost of sheet metal laser cutting depends on various factors including material type, thickness, complexity of the design, production volume, and machine time.

For a bespoke sheet metal laser cutting quote, get in touch with the experts at The Laser Cutting Co.