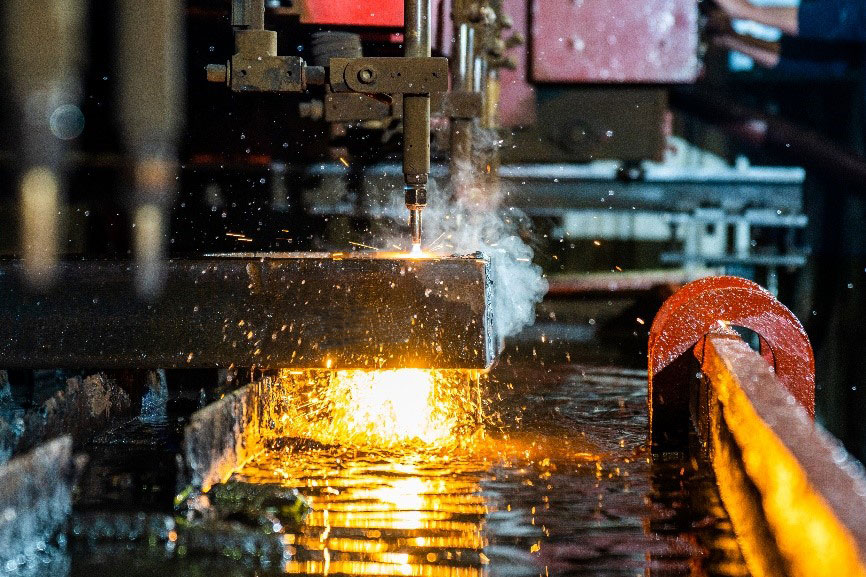

Precision Laser Cutting for High-Demand Industries

At The Laser Cutting Co., we procure and cut materials that are integral across heavy-duty and specialised industries. We offer a highly diverse stock profile, including reversing mill plates (RMP) that are frequently used in oil and gas sectors, offshore construction, engineering, and more.

Produced from steels via a hot-rolled and slab conversion process, unlike coil-rolling, the outcome leads to a high-tensile plate that offers larger sheets, greater structural integrity, and excellent machinability properties, even on thicker sheets. Our capabilities also allow us to produce various grades and thicknesses to meet your bespoke project requirements.

By offering both laser and open section cutting all under one roof, our fleet of cutting-edge lasers can cut steel sheets with ease, expediting supply chains that remain cost-effective, without jeopardising quality.

Reversing Mill Plate Applications and Grades

Due to reversing mill plates often being utilised in heavy-duty and high-spec industries, we always guarantee full compliance and certification for customers’ peace of mind. We deliver reliable options for applications like pressure vessels and offshore steel purposes, including processing and supplying typical grades, such as:

Structural Steel

- S235 - General-purpose structural steel

- S275 - Low-carbon manganese steel

- S355 - Higher strength, low-carbon manganese steel

- S460 - Higher strength and high yield steel

- S690 - Incredibly high-strength, with a minimum yield of 690 MPa

Abrasion-Resistant (AR)

- AR400

- AR450

- AR500

Offers exceptional high-tensile strength and durability, suitable for adverse and harsh conditions.

Pressure Vessels

- A516 - Ranging from grades 60, 65, and 70

- P265GH - Suitable for use in high temperature environments

The size of plates that we can procure and supply is entirely flexible to your requirements, with thicknesses often ranging from 6mm up to over 250mm, depending on the source mill.

Applications of Reversing Mill Plates

Reversing mill plates are frequently used in many heavy-duty sectors, where high tensile strength is critical. These include, but are not limited to:

- Construction & Engineering: Structural components, such as building frameworks, rail, and bridges.

- Shipbuilding: Corrosion-resistant and high-strength components.

- Offshore & Energy: Highly specialised and durable pipes for use in harsh conditions, including essential parts within the oil and gas sectors.

- Pressure Vessels: High-tensile and adaptable steel parts that can withstand varying temperatures and processes.

- Mining: High-tensile and adaptable steel parts that can withstand varying temperatures and processes.

Advantages of Laser Cutting Reversing Mill Plates

Laser cutting delivers a broad range of advantages, some of which include:

Unparalleled Precision

Flexible handling of very thick reversing mill plates with flame and waterjet cutting

Remarkable Versatility

Our laser cutters can seamlessly handle complex geometries and intricate designs across small and large-scale projects.

Complex Designs

Versatile capability with intricate and complex designs that are cut with ease

Enhanced Productivity

Automated, high-efficiency and productivity, with fast lead times

Clean, Burr-Free Edges

Achieve clean, burr-free edges with minimal warping or distortion, made possible by our focused heat laser processes.

Reduced Waste

Maximises efficiency, nesting materials, and utilising sustainable manufacturing.

Metal Profiling for Thick Reversing Mill Plates

Where greater material thickness is of importance, reversing mill plates are a popular choice. The Laser Cutting Co. implement a range of cutting technologies suited to the unique properties of reversing mill plates.

Laser Cutting

When working within high-precision industries, laser cutting can achieve a flawless finish, even within fine tolerances, which is difficult to achieve through manual machining. For medium thicknesses on reversing mill plates, our laser cutters are most suitable, delivering:

- Narrow kerfs and minimal heat-affected zones

- Cleaner edge finishes within fine tolerances

- Rapid lead times and optimised nesting for maximum yield

Flame Cutting

Heavy reversing mill plates, which often include 80mm, 150mm, 200mm and above, benefit from processes such as flame cutting.

- Suitable for thick, high-strength grades

- Offers consistent, vertically aligned cuts even on deep sections

- Provides reliable accuracy for structural and pressure vessel components

Waterjet & Bevel Cutting

For projects where heat must be minimised, or if intricate and detailed designs are required on very thick reversing mill plates, then waterjet cutting is the ideal choice.

- Cold cutting process, eliminating heat-affected zones

- Can process incredibly thick mill plates that may not be suitable for lasers and thermal cutting

- Bevel waterjet cutting delivers weld preps, chamfers, and angled cuts on large plates

- Seamless edge quality and reduced post-processing

Quality Assurance

Certified Quality Laser Cutting

At The Laser Cutting Co., we offer guidance and reassurance throughout the process. We provide full traceability, quality assurance, and certifications that adhere to compliance standards, ensuring you only receive the highest level of care and quality.

Whether you’re enquiring about offshore steel components or parts for heavy machinery, we can facilitate your project across all phases. From material procurement, CAD designs, to secondary processes such as pressing, laser etching, or countersinks of any size, we can help you achieve exceptional quality parts.