Quick Links

In modern manufacturing, tube laser cutting is a common method that is often utilised to cut metal tubes with high-powered lasers, achieving incredibly accurate results, which has increased the demand for such machines over the years.

However, not all tube laser cutting machines are built the same. One of the key differences focuses on the number of axes a machine can move along, which affects the overall type of cut outcome it can achieve. Within this guide, we explain the main difference between 3-axis and 6-axis tube laser cutting, and how each type impacts precision, complexity, and the type of job they’re best suited for.

What Does “Axis” Mean in CNC and Laser Cutting?

In CNC, Computer Numerical Control, and laser cutting, an axis refers to the position in which the machine can move or navigate the laser position. The basic axes include:

X = left to right

Y = front to back

Z = up and down

Machines with more than three axes can also rotate or tilt the cutting head, including the material. These are often labelled as A, B, and C axes.

Why Do More Axes Matter?

The more axes a machine has, the more flexible and versatile it can be. With the added movement, these types of machines can perform more complex cuts, varying angles, and better control over the shape and edge quality.

What is 3-Axis Tube Laser Cutting?

A 3-axis laser cutter moves in just three straight directions, X, Y, and Z. It can position the laser to cut through tubes accurately, but without changing the angle of the cut.

Capabilities:

- Cuts straight lines, holes, and simple shapes

- Suitable for basic slots and notches

Limitations

- Limited angle control since it can only cut straight through the tube

- Not ideal for complex shapes or bevelled edges

Typical Applications

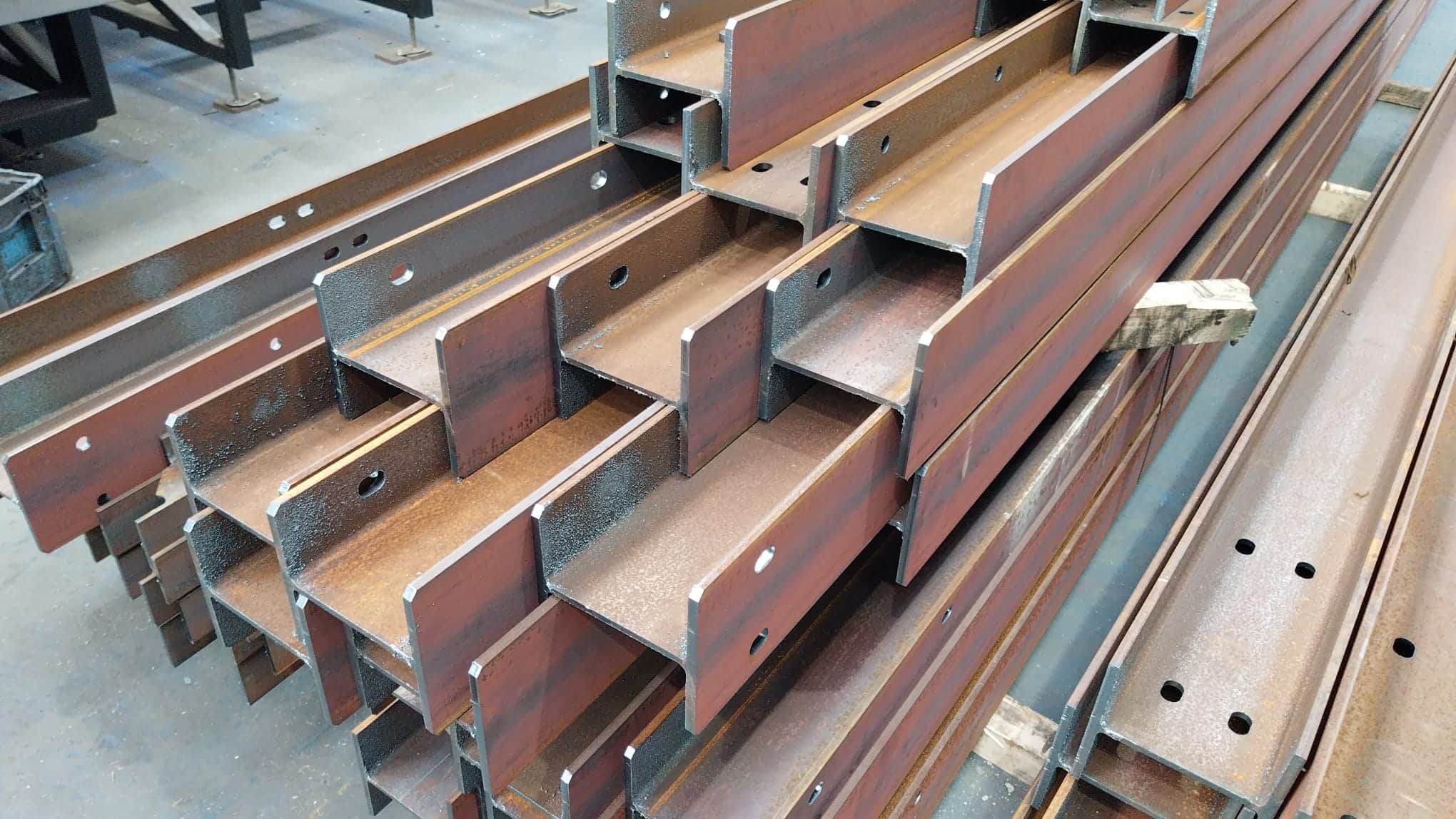

- Furniture frames

- Structural supports

- Automotive brackets

- High-volume, straightforward production

What is 6-Axis Tube Laser Cutting?

A 6-axis tube laser cutter includes utilising the three standard directions (X, Y, Z), plus the use of rotational and tilt movement, typically A and B, and occasionally C axes. This allows the laser to approach the tube from different angles, making it possible to perform much more complex and angled cuts.

Capabilities:

- Can cut bevels and angled edges

- Handles complex and irregular geometries

- Can prepare edges for welding in a single pass

Advantages

- Greater design freedom

- Often removes the need for extra machining or finishing

- Saves time and accuracy on complex cut parts

Typical Applications

- Aerospace components

- Architectural parts

- Automotive

- Highly precise and complex projects

Choosing Between 3-Axis and 6-Axis

Selecting the right laser cutting system depends on the complexity, precision requirements and scale of the project. Several key factors are important to consider to help guide the decision.

Design Complexity

If your parts involve straight cuts, simple holes, or standard features, then a 3-axis laser cutter will be sufficient. However, for angled edge requirements, bevels, or more intricate geometries, a 6-axis system offers the flexibility needed to cut with ease.

Accuracy

3-axis machines provide reliable precision for most general applications but can potentially fall short where a project demands tight tolerances, clean edge finishes, or cuts that align precisely with welded joints. A 6-axis machine can deliver exceptional accuracy with fewer adjustments, finishes, and corrections needed.

Budget and Scale

A 3-axis machine is more cost-effective, particularly when applied to high-volume production of components that require uniform outcomes. 6-axis cutters have a higher initial investment, but can save time and expenses over project timelines by reducing the need for secondary processes, such as deburring and weld-prepping, as they already deliver high-specification parts.

- Opt for 3-axis if you’re working on straightforward designs, need rapid turnaround, and want to keep costs low.

- Choose 6-axis if you require more complex, highly precise cuts that may require edge preparation.

Achieve Precise and Quality Tube Laser Cutting

At The Laser Cutting Co., we are proud to deliver one of the UK’s leading tube laser cutting services, with 3-axis lasers for simple cuts, to advanced 6-axis machines capable of facilitating complex geometries within fine tolerances and enhancing design possibilities, irrespective of project size.

We are committed to delivering the highest quality of service for our customers, reinforced by over four decades of experience in the metal profiling sector. For tailored tube laser cutting solutions and guidance, get in touch with a member of our expert team today.