Sheet metal profiling is an essential process across industries such as automotive, aerospace, manufacturing, and construction, providing reliable parts and prototypes across a broad spectrum of applications. However, when components fail it can lead to additional post-processing or repairs, which is not only time-consuming but contributes to safety hazards and drives up additional expenses. The key to avoiding failures means making careful material selections, refined designs, and sourcing professional profiling services.

Quick Links

Contributors In Sheet Metal Part Failure

To enhance current processes, and effectively avoid sheet metal defects, it’s essential to understand the key factors that contribute to such errors. Recognising areas that create shortfalls in production can help minimise waste and mitigate costly mistakes before they occur.

Material Selection

The choice of material is fundamental to how sheet metal performs. Opting for certain metal types that are not suitable for particular processes, such as performing poorly in certain environments or not meeting load-bearing requirements, can result in premature failure. For example, mild steel may be prone to rust in higher humidity environments, while aluminium may not be the best selection for some heavy-duty applications. Understanding the properties of each metal type, such as tensile strength, corrosion resistance, and versatility, is paramount to avoid potential failures.

Manufacturing and Profiling Defects

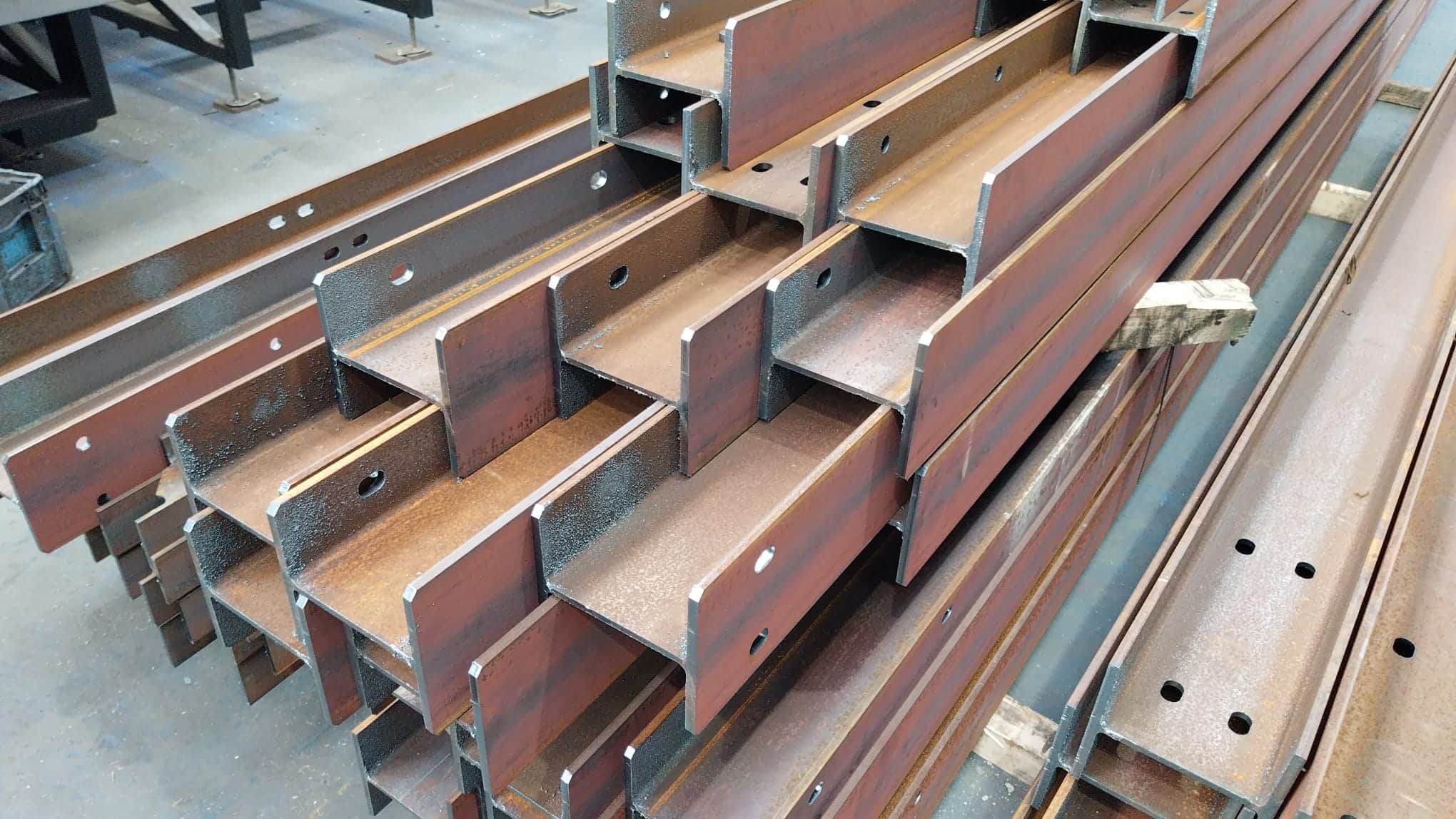

Even the most suitable and sufficient metal type can become defective if the manufacturing process is not up to par. Processes that result in improper profiling, welding defects, rough burrs, or inconsistent forming can affect the overall finish and structural integrity of the part. This can lead to issues such as distortion, cracking, inaccuracy, blemishes, corrosion, and springback if left unaddressed.

Design Flaws

Poor design is a major contributor to failures within profiling. Common requirements such as sharp corners, tight tolerances, or intricate designs make the part more susceptible to defects. Additionally, designs that do not account for factors such as thermal expansion, weight distribution, or external exposure are more likely to be affected.

Environmental Exposure

Certain conditions can significantly affect sheet metal and parts, those particularly of note are high moisture, salty air, and extreme temperature environments. Corrosion is a common issue in outdoor or coastal locations, where moisture and saltwater can accelerate the degradation of unprotected metals. Exposure to harsh chemicals, UV light, or temperature fluctuations can also cause materials to weaken over time.

Control Measures to Mitigate Sheet Metal Failure

The prevention of sheet metal part failure can be controlled by adopting best practices throughout the entire production pipeline. These strategies help to reduce the risk of failure by promoting knowledge and machining capability before projects are undertaken.

Choosing the Right Material

As mentioned previously, choosing the most suitable metal type for a project can drastically affect the outcome. Project requirements should be considered before commencing, with an understanding of the strength, corrosion resistance, and ductility required. Additional coatings such as galvanising or powder coating can provide extra protection against rust and wear from environmental factors.

Designed for Durability

Design considerations must be examined in order to determine potential areas of concern. Weight should be evenly distributed to prevent pressure points and causing stress on weak points, which can lead to dangerous faults. It’s also imperative to work within the tolerances specified for the project since small deviations can lead to functional issues that create flaws within the design. Ultimately, the most suitable type of metal should be carefully selected to cater to the unique load-bearing requirements of each project.

Implementing Quality Processes

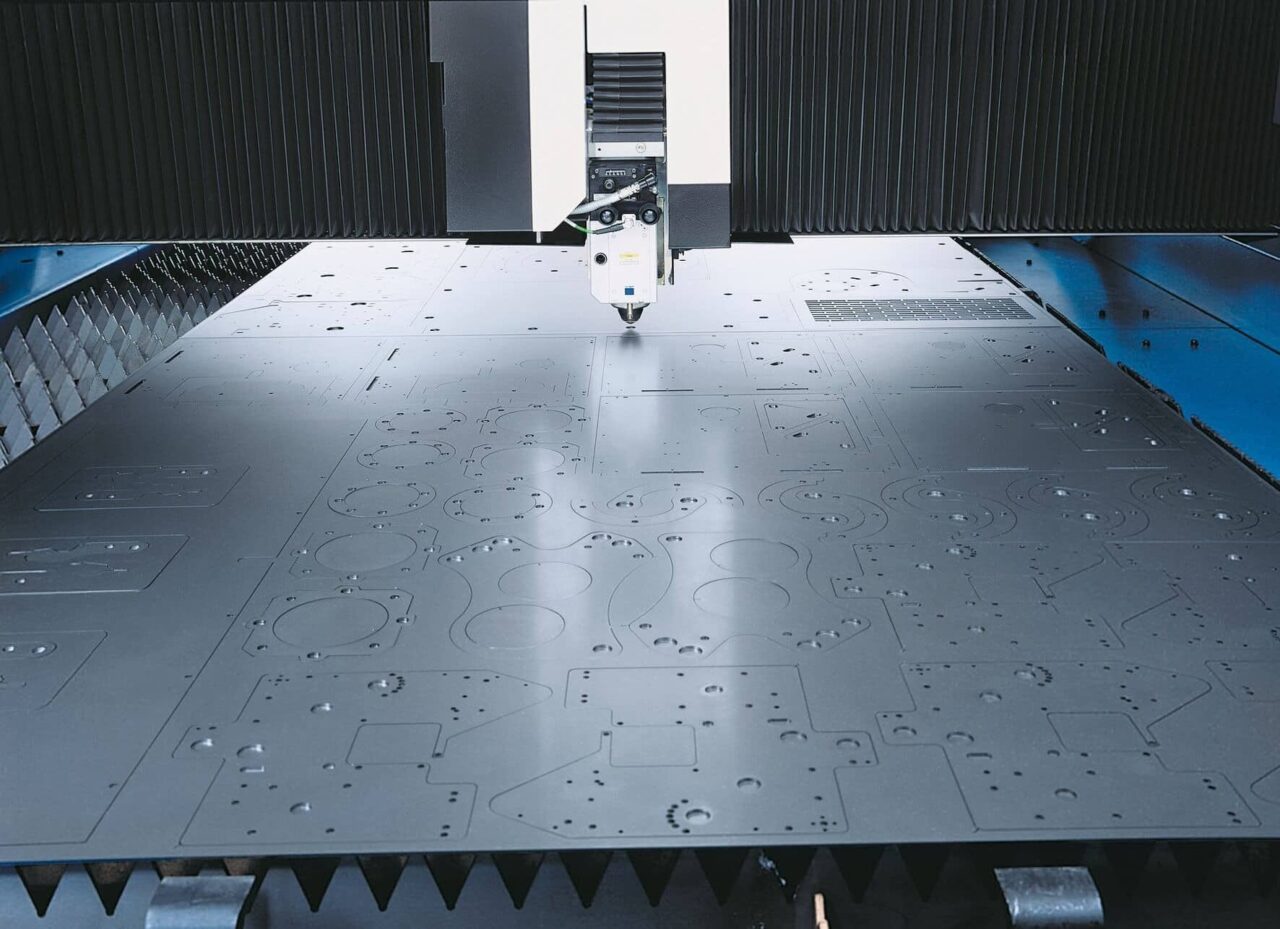

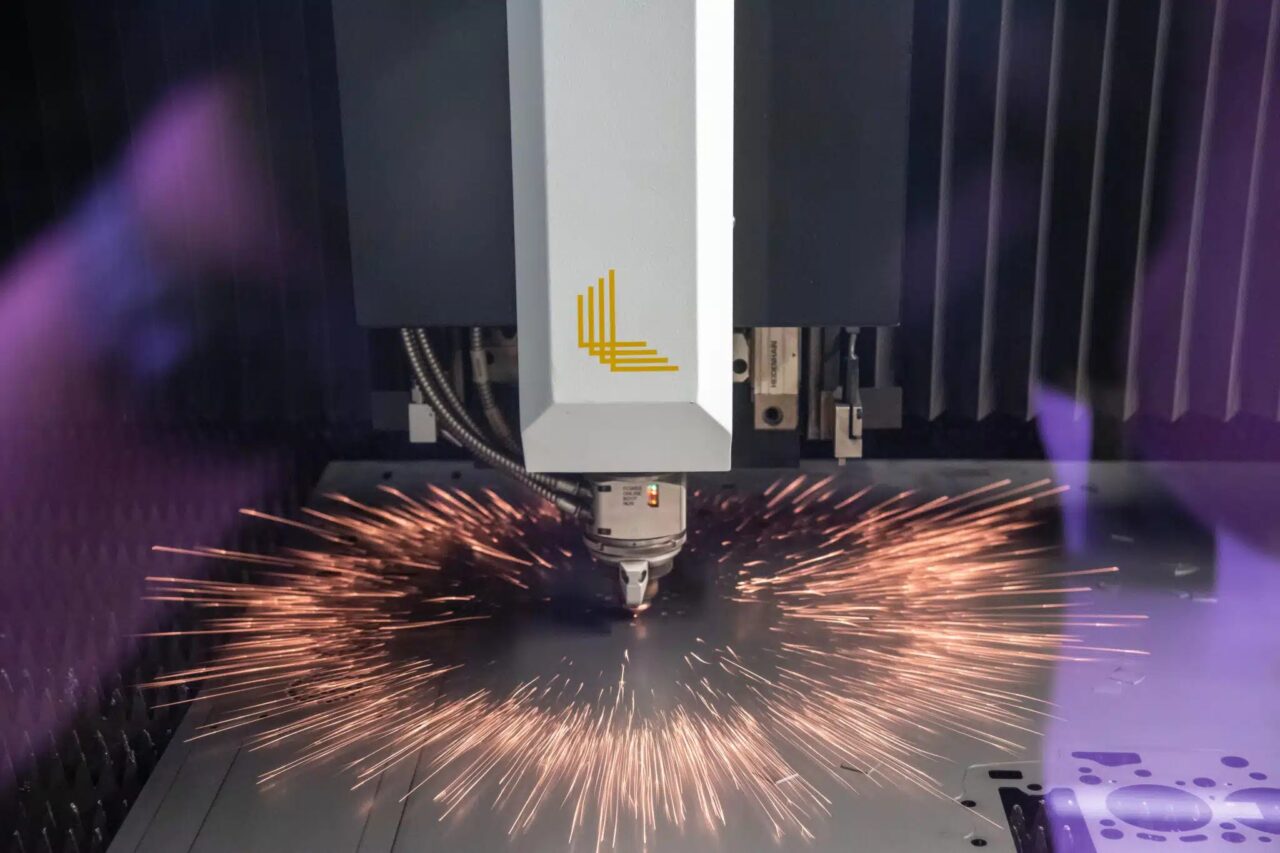

Accurate and consistent manufacturing is key to ensuring the integrity of sheet metal parts. Advanced technology such as laser cutting can help achieve high-quality finishes within strict tolerances, reducing the likelihood of defects. Employing quality assurance throughout the profiling process ensures that regular testing and visual examinations can identify potential flaws early in the pipeline.

Protective Coatings and Treatments

Post-processing coatings and treatments can be applied after profiling to ensure parts achieve a polished and refined finish. Powder coatings can enhance sheet metal longevity and provide valuable protection against corrosion and light, while deburring can eliminate sharp and rough edges left over on metal parts. Additionally, heat treatment can be used to improve tensile strength, and shot blasting is utilised to prepare surfaces.

Regular Maintenance and Inspections

Conducting routine maintenance and inspections is crucial to identifying potential issues before they lead to failure, whilst also protecting the welfare of staff onsite. Consistent equipment checks for signs of wear or damage can help catch issues before they happen. Real-time monitoring systems can provide ongoing data on the condition of a machine, ensuring that preventative maintenance and repairs are carried out efficiently.

How to Handle Defects in Profiling

Failures can occur even if all the necessary precautions are taken, which is why it’s important to understand the protocols that caused the issue to occur, and how to efficiently handle errors.

Isolate the Component

If the sheet metal becomes compromised during operations, it’s imperative to halt production in order to prevent further damage to additional material components or equipment, isolating the affected parts.

Conduct an Analysis

Once a part has been isolated, performing an analysis is important to determine the underlying issue. This investigation should be detailed and assess all aspects of the process, from the material choice to manufacturing issues, and flaws within the design.

Consult with Professionals

In more complex scenarios, it may be necessary to communicate with engineers, manufacturers, or suppliers to assess where failure could have occurred and to discuss where modifications can be applied. Their expertise in the field can provide insight that can be implemented across long-term solutions.

Redesigns and Upgrades

Once assessment is complete, a redesign or upgrade on the material type may be necessary. This is particularly notable when considering design flaws and potential structural issues. Alongside this, an update in processes or the profiling method used may be best utilised to ensure long-term success which can be applied to similar projects in the future.

Documentation

For future reference, it’s important to document and log failures and analysis reports. This becomes an invaluable resource that can be applied to current processes and prevent similar issues from occurring. Keeping a record of corrective measures helps processes to remain compliant, develop safety audits, and remain consistent with future design improvements.

Achieve Exceptional Metal Profiling with The Laser Cutting Co.

With more than 40 years of metal profiling experience, The Laser Cutting Co. delivers extensive knowledge to a wide range of sectors and their unique project needs. Our team of expert engineers specialises in laser cutting, bending, welding, bevel and countersink, all provided in-house.

We are committed to delivering the highest standard of quality, which is why we utilise state-of-the-art laser cutting beds and smart design software to achieve detailed designs and streamline the production process. For bespoke metal profiling solutions, reach out to a member of our expert team today.