Quick Links

Laser cutting is an essential process in manufacturing, often associated with heavy industrial uses, such as automotive, aerospace, and construction industries. However, laser cutting offers a wide spectrum of purposes due to its undeniable ability to achieve high precision, versatility, and clean edges. This can range from hobbyists through to large-scale sectors, including several markets in between. In this article, we explore five industries that frequently utilise laser cutting and the ways in which they facilitate and innovate each sector.

Construction and Infrastructure

Structural steel is essential across the construction of buildings, bridges, and all infrastructure projects. Laser cutting is frequently relied upon to produce open structural sections such as beams, channels, and box sections, down to exact tolerances. Complex designs, bolt-holes, and weld-prep properties can all be integrated across a singular cutting process, effectively reducing time spent on manual handling and fabrication.

Within large-scale projects, laser cutting supports procurement by delivering consistent quality, even across demanding sectors. Structural section and open section laser cutting ensure that parts are delivered ready to install, meeting the strict safety and regulatory standards required by such industries.

Food and Beverage

Surprisingly, for many, laser cutting plays a pivotal role within the food and beverage industry. The technology is frequently utilised across processing, packaging, and components to be used within the facility. Across production, laser cutting is also instrumental in producing conveyors and cleanroom equipment. This is valuable since laser cutters can avoid the risk of contamination, which is essential in an industry where food hygiene regulations are stringent.

Laser cutting can also be used across packaging designs and promotional products for retail purposes, offering the ability to cut intricate shapes and engrave logos onto wood, acrylic, or other suitable materials. This is incredibly beneficial in seasonal or campaigns where the rapid procurement of design is required. Laser marking is also incredibly useful for supplying traceability codes on food packaging to ensure compliance is always met.

Set Designs

Industries such as film, television, arts, and exhibitions all move at a rapid pace, often requiring unique and bespoke set elements within relatively short lead times. Laser cutting is excellent at processing complex geometries and intricate designs that often require prototyping or expedited changes. This allows designers to take drawings, turn them into CAD designs through smart design production, and produce flawless results within minute tolerances. Laser cutting is also a versatile process, with the ability to cut materials across MDF, foam, acrylics, thin metals, and more, creating architectural and structural components with high execution.

Etching and engraving once again serve a primary purpose, offering detailed designs, surface textures, lettering, and symbols across one-off and large-scale productions. Overall, laser cutting helps reduce expenses while offering faster response times and streamlining build processes.

Renewable Energy

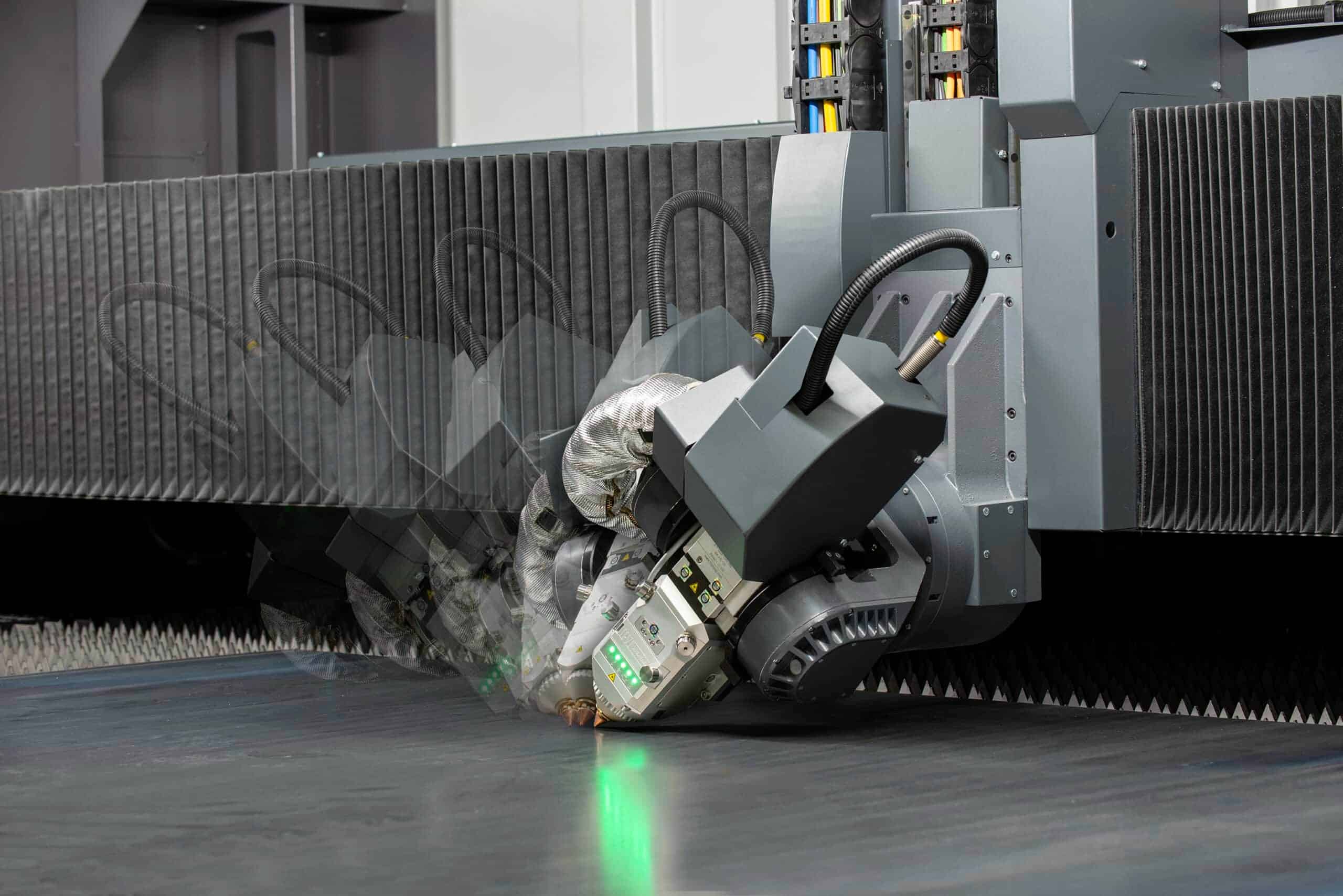

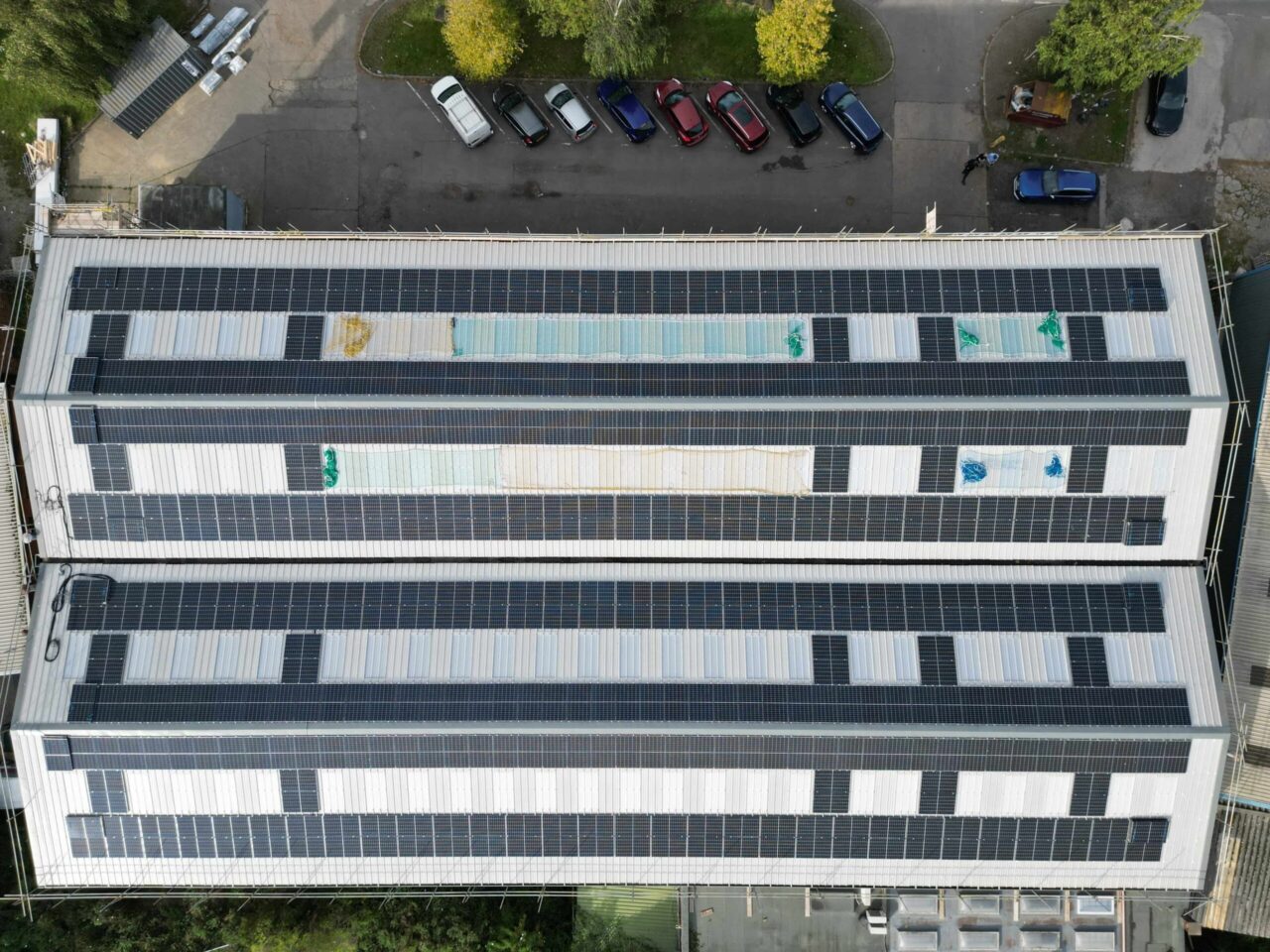

The increasing demand and need for renewable energy has been rising in the modern age. This has led to recent innovation in how the components of this technology are designed and manufactured. Laser cutting for the renewable sector is increasingly common, from solar panels to wind turbine production, becoming instrumental in profiling and producing precise metal parts and composite materials.

For solar energy sources, thin metal backings, frames, and reflective materials are processed with lasers to maximise their consistency. In battery and energy storage, laser technology is useful in producing enclosures, heat shields, and internal structural parts to tight tolerances. The ability to produce burr-free edges across many material types also eliminates the risk of performance issues, allowing for longevity across all sustainable solutions.

Agricultural

The agricultural sector and the need for heavy machinery often rely on reliable, high-performing parts that can withstand harsh working and weather environments. Laser cutting supports these industries by enabling the rapid procurement of durable and complex parts, such as framework, enclosures, weld-prep parts, brackets, and guards, all produced to meet tight tolerances and consistent repeatability.

Typically, equipment, parts, and bespoke open section cutting requests are where laser cutting shines, offering the flexibility required to handle prototypes, custom designs, and scaled production. Materials such as thick mild steel, abrasion-resistant metals, and stainless steels are processed with minimal distortion, allowing manufacturers to meet performance and longevity requirements while streamlining production timelines.

The Reach of Laser Cutting

As modern manufacturing and industries continue to evolve, so does the demand for laser cutting. Such technology offers innovation and higher-quality output compared to traditional methods, proving itself as an indispensable process across sectors.

Innovate Industries with The Laser Cutting Co.

At The Laser Cutting Co., we work closely with a wide range of sectors to provide customisation, remarkable precision, and high-grade finishes within rapid lead times. We help bring ideas to life, regardless of industry and project complexity.

We are proud to offer comprehensive services, from advanced laser cutting to bevelling and smart design production for all profiling requirements. For bespoke, reliable, and diverse laser cutting solutions, get in touch with an expert member of our team today.