Quick Links

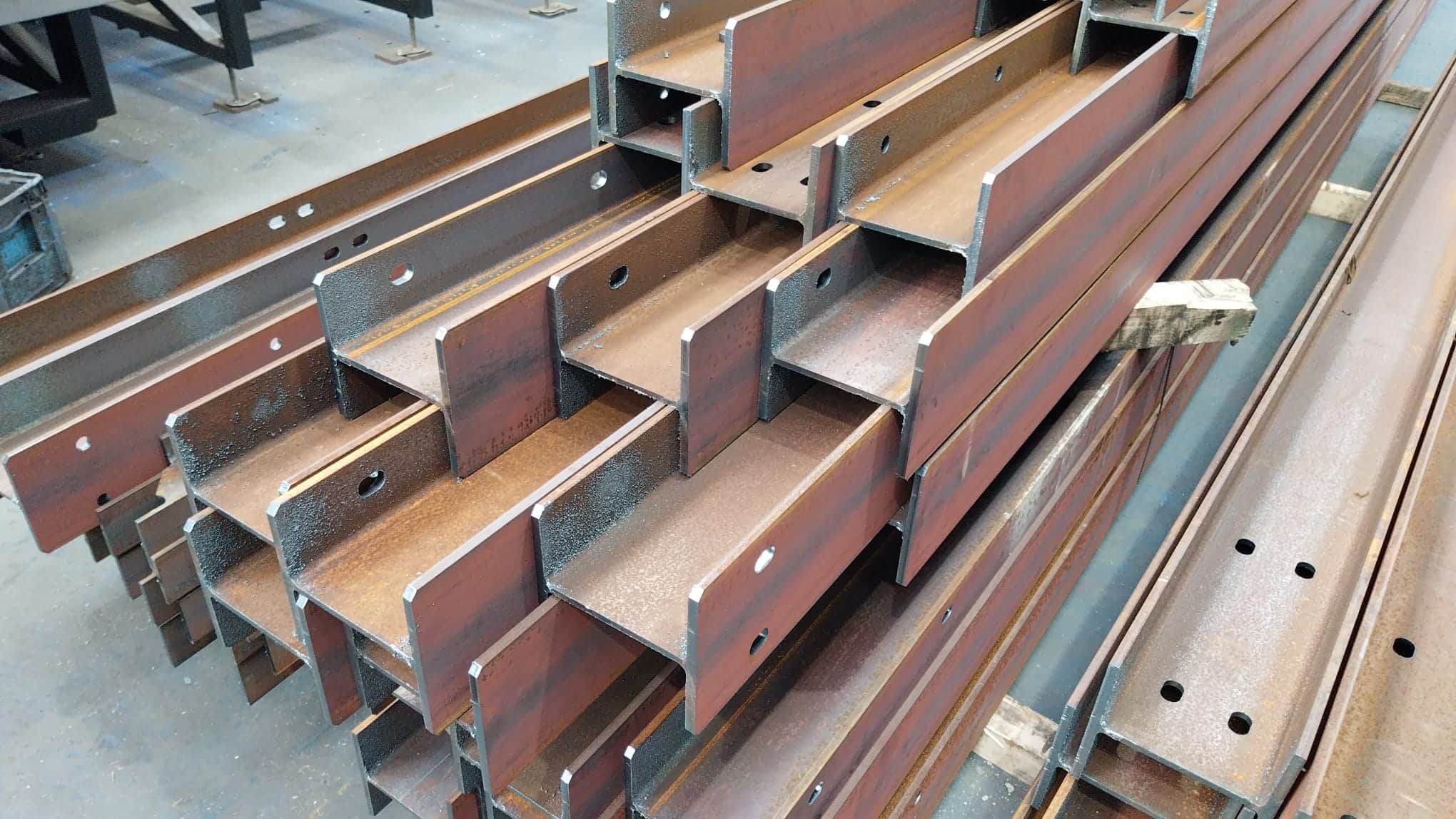

Steel fabrication continues to change as the need for faster turnaround, improved accuracy, and greater control over cost is in demand. An important decision made early on in the project is choosing to profile components with laser cutting or traditional drilling and coping lines.

While both methods have an important position in modern manufacturing, they each serve different purposes. Understanding their range of capabilities and suitable applications is integral to avoiding wasted money, time, and rework occurring down the line.

The Difference Between Drill Lines and Laser Cutting

Laser cutting is well-known for being an automated process that uses a high-powered laser mounted on a multi-axis head. The laser works directly from CAD files, cutting metals and other materials with ease, consistency, and exceptional accuracy across different projects. Laser cutting machines are capable of cutting holes of any shape, including slots, tabs, mitres, bevels, weld-preps, contours, and complex geometries for many designs. They are ideal for producing:

- Hollow sections (HSS, RHS, SHS)

- I-beams and H-beams

- Channels and angles

- Bespoke and structural profiles

- Intricate profiles

Drill lines utilise a traditional approach to profiling through mechanical methods. They typically use:

- Beam drill line (often multi-spindle)

- A coping robot or plasma coper

- Saw for end cuts

Drill lines are widely used for standard structural steel preparation, such as drilling round bolt holes, straight copes, block-outs, and beam ends, especially on large-scale construction projects.

Accuracy and Cut Quality

One of the main advantages of laser cutting is its ability to be incredibly precise, cutting materials within fine tolerances. In fact, laser systems often achieve tolerances in the range of +-0.1 – 0.25 mm, producing clean, burr-free edges with minimal heat distortion. This makes laser cutting an ideal solution for scenarios where precise assembly is paramount, including tabs, slots, and tight weld joints.

Drill lines also provide great accuracy for drilled holes, typically around +-0.5mm, but thermal coping processes, such as plasma cutting, can introduce heat-affected zones. This can be fine on 2D shapes and simple designs, but is often difficult on more complex projects.

Speed and Throughput

Drill and coping lines are designed for speed when needing to process large volumes of structural steel. For repeatable patterns, such as beams with uniform hole layouts and straight copes, they are extremely efficient and hard to beat.

However, laser cutting really shines when complex geometries are required. While cutting is slower on thick materials, laser cutting makes up for this by replacing the need for many other additional services, such as drilling, milling, grinding, and manual torch cutting. Overall, this reduces the time spent on production, particularly on more detailed jobs.

Geometry and Design Flexibility

Laser cutting often excels with its flexibility, producing non-round holes, angled and bevelled cuts, multi-axis chamfers, pipe intersections, tube profiles, and decorative or architectural cutouts. This makes laser cutting well-suited for project designs where freedom is important.

Drill lines, in comparison, are often more limited. They typically handle straight cuts, round holes, and 90° copes, with minimal ability to process bevels, chamfers, or difficult geometries.

Labour and Downstream Efficiency

Since laser cutting has the ability to deliver near-finished parts, it often eliminates the need for manual drilling, grinding, and fit-up fixtures. Components can be designed with self-fixturing tab and slot features, allowing for more accurate and faster assembly.

Drill line processes usually involve multiple handling steps between sawing, drilling, and coping stations. Plasma cut copes many still require cleanup, with non-standard joints often needing additional manual fitting.

Material Thickness Considerations

Laser cutting is capable of cutting across a wide range of thicknesses with ease, depending on the material type. Some typical limits include:

- Mild steel up to 50mm

- Stainless steel up to 50mm

- Aluminium up to 40mm

- Copper, brass, and bronze up to 20mm

- Titanium up to 10mm

Drill and coping lines handle heavy structural steel, with webs and flanges that often exceed 80mm, making them great for profiling construction steel.

Choosing the Best Process for Your Project

Deciding between laser cutting and drill lines ultimately depends on complexity, volume, material thickness, and precision requirements. Projects that need intricate profiles and reduced fabrication time will often benefit from laser cutting, while traditional structural applications may suit drill line processing.

Laser cutting is best for:

- Flatbed, complex, or non-standard geometry

- Tubes and hollow sections

- Architectural or decorative designs

- Precision machinery

- Reducing fit-ups and assembly labour

- Mixed or short production runs

- Weld-prep bevels and tight tolerances

Drill lines are best for:

- Standard I-beam structural work

- Very thick steel sections

- High-volume, repetitive projects

- Conventional bolted connections

- Large-scale construction fabrication

Streamline Projects with Quality Laser Cutting Solutions

At The Laser Cutting Co., we work alongside customers to find the best material, design, and outcome for each project. Our fleet of advanced laser cutting beds is equipped to profile a variety of materials up to 50mm thick, or even greater with waterjet cutting, including plasma cutting, bevels, chamfers, contours, and complex designs, with highly repeatable results.

If you’re looking for high-quality prototyping and execution on flatbed or multi-axis geometries, then get in touch with a member of our team today.