Quick Links

PPAP, also known as the production part approval process, is a quality management system that is used to guarantee suppliers have the capability to produce consistent results across design, manufacturing, and customer outcomes. This system was originally developed for the automotive industry; however, PPAP is now widely adopted by many industrial and commercial sectors that have a keen eye for precision and reliability. This includes laser cutting and profiling services, where the requirement for high-quality assembly and complex fabrication is essential on a daily basis.

Why PPAP is Important to Internal Procedures

The primary goal of PPAP is to reduce risks that can occur along the manufacturing process. Across the pipeline, it’s imperative that manufacturers and suppliers submit documentation that details specifications and tolerances of materials, with the ultimate aim of reducing the likelihood of defects, reworks, or expensive recalls. Within laser cutting, this includes ensuring that specific components will fit together and perform according to a client’s expectations, irrespective of the production scale.

PPAP is a particularly useful system when undertaking internal changes, which can include procuring new materials, changing suppliers, or simply altering the way operations are conducted. This is beneficial as it provides confidence for both manufacturers and the suppliers, ensuring quality standards are always strived to be met.

What are the Five Levels of PPAP?

The process behind PPAP is often summarised into five key levels, determining how much documentation is required at each stage.

Level One

A supplier will submit a Part Submission Warrant (PSW) to confirm that the part meets the expected specifications.

Level Two

The PSW is submitted, along with product samples and some limited supporting data.

Level Three

This is the most commonly requested level and requires the PSW, product samples, and complete supporting documentation. This will include material certifications, dimensions, and process capability studies.

Level Four

This level requires all the information expected in level three, but tailored according to the client’s request.

Level Five

As the most in-depth level, it will require the information from all the previous four stages, which will be reviewed internally at the supplier’s manufacturing facility.

Each level is representative of the additional risks and complexity of a project or component. Within laser cutting, where precision and high-quality are key, level three is often a comfortable choice that fulfils confidence in all the parties involved.

The Key Components of a PPAP Submission

The process of submitting a production part approval includes several key elements:

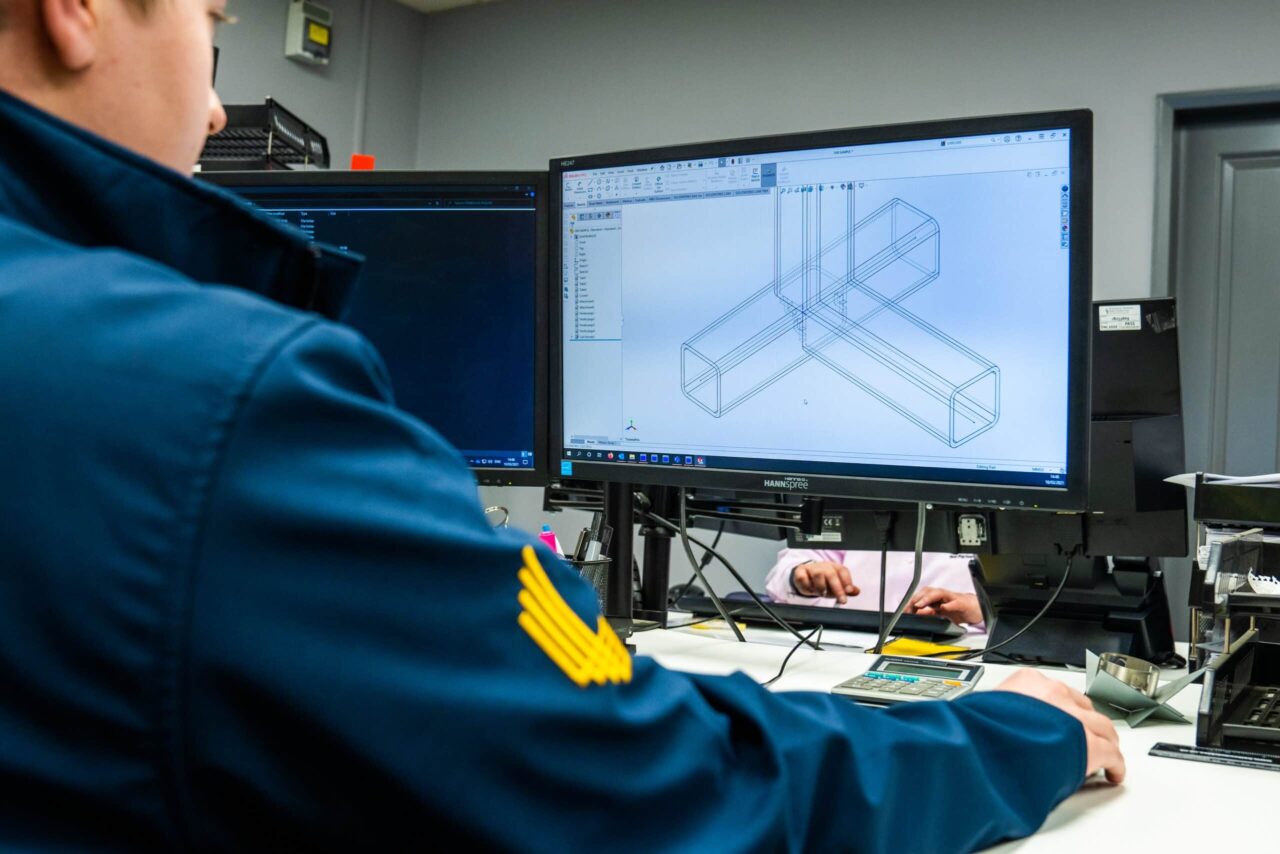

Design Records

The original engineering drawings or CAD files should be retained, ensuring the part matches the initial design.

Engineering Change Documents

If any modifications have been made to the original design, then it must be noted since it could potentially affect production and product outcome.

Process Flow Diagram

Including a visual map is beneficial when visualising every step of the manufacturing process.

Process Failure Mode and Effects Analysis (PFMEA)

This method identifies potential risks in production and how they can be mitigated.

Control Plan

This documentation details existing inspection methods, measurement techniques, and the frequency of quality control.

Dimensional Results

Valuable evidence that ensures parts meet all the critical measurements and tolerances.

Material and Performance Certifications

All raw materials, coatings, and treatments used must be reliably verified.

Sample Production Parts

Sample parts produced under the same production conditions must be able to demonstrate thorough capability.

The Benefits of PPAP

- Implementing PPAP ensures clients can source highly precise and quality components.

- All issues are identified before full-scale production begins, reducing the risk of defects.

- The system delivers a baseline for consistency across batches, resulting in reliable quality.

- A formal record of expectations, tolerances, and approvals enhances communication with the supplier.

- Sectors that rely on high-quality parts can remain regulatory and industry compliant.

How PPAP Applies to Laser Cutting Fabrication

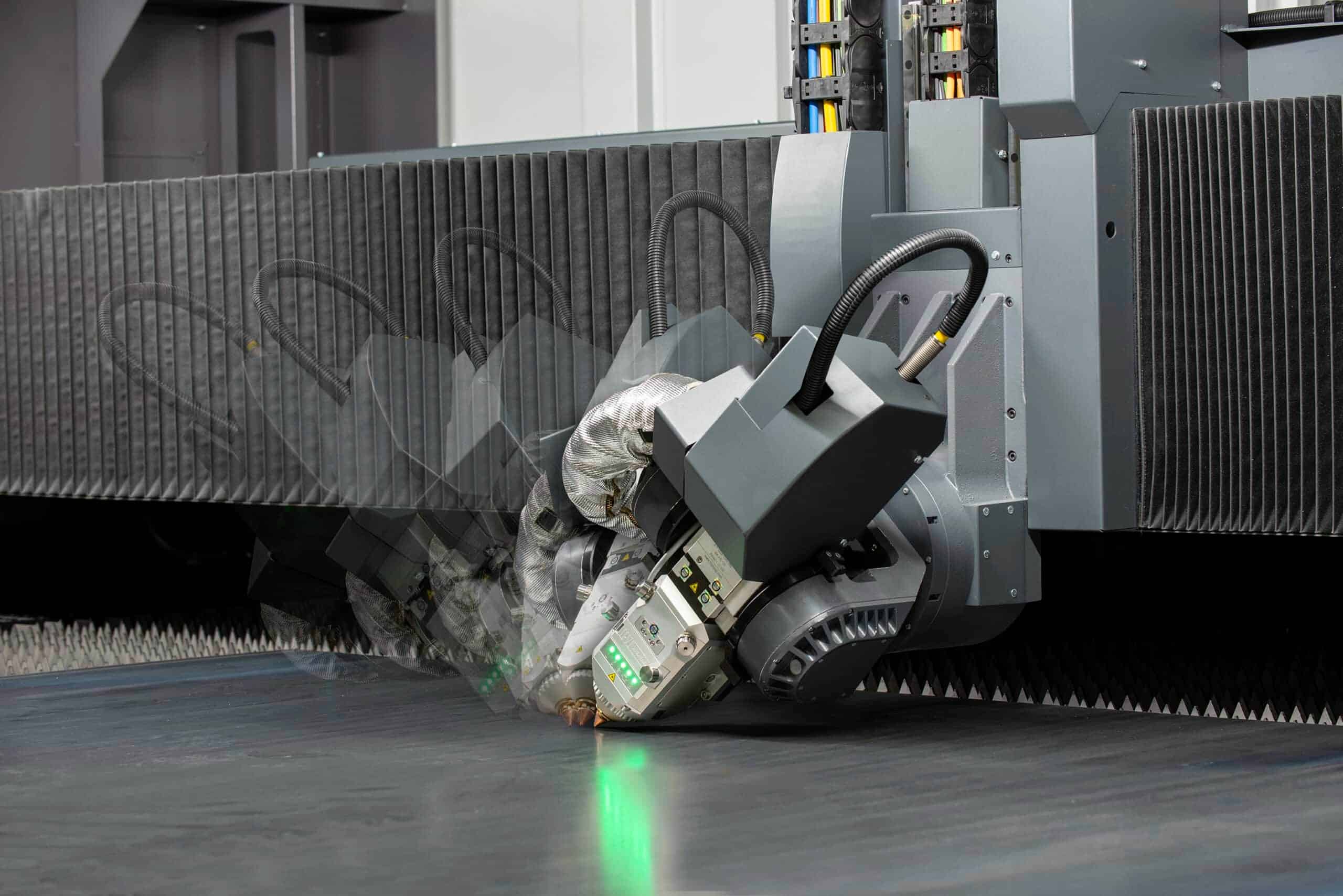

Within the laser cutting industry, PPAP is a foolproof methodology that encompasses all aspects of operations, from prototyping to full production runs. Where high-precision, tight tolerances, edge quality, and correct material properties are paramount, PPAP is highly valuable.

- Validates cutting parameters and machine settings

- Verifies that materials supplied meet the required standards

- Confirms that the finished parts meet all dimensional and functional expectations

- Documented evidence to industrial clients that parts are production-ready

Enabling Exceptional Quality with The Laser Cutting Co.

At The Laser Cutting Co., the production part approval process is a vital tool as part of our internal processes, ensuring all our valued customers receive only the highest level of execution and service.

We are proud to deliver a range of laser cutting services from large and open section cutting to tube laser cutting, bevel and countersink, and smart design production. For tailored, quality laser cutting solutions and guidance, get in touch with a member of our expert team today.