Smart Design Production

Design for manufacture is optimising parts for efficient downstream processes and product assembly.

The in-house design team at The Laser Cutting Co. take a holistic approach to part optimisation, considering everything from material waste to reduced handling and assembly processes, to realise downstream efficiencies.

The more complex a design is, the higher the risk. The aim of The Laser Cutting Co.’s CAD design service is to reduce component volume, reduce material waste, and reduce overall complexity. The results are an average 50% cost saving for customers.

#Fewer, more accurate parts that are fast to assemble deliver significant savings for manufacturers including reduced assembly times, reduced handling and storage, and a reduction in defective parts.

Efficiency

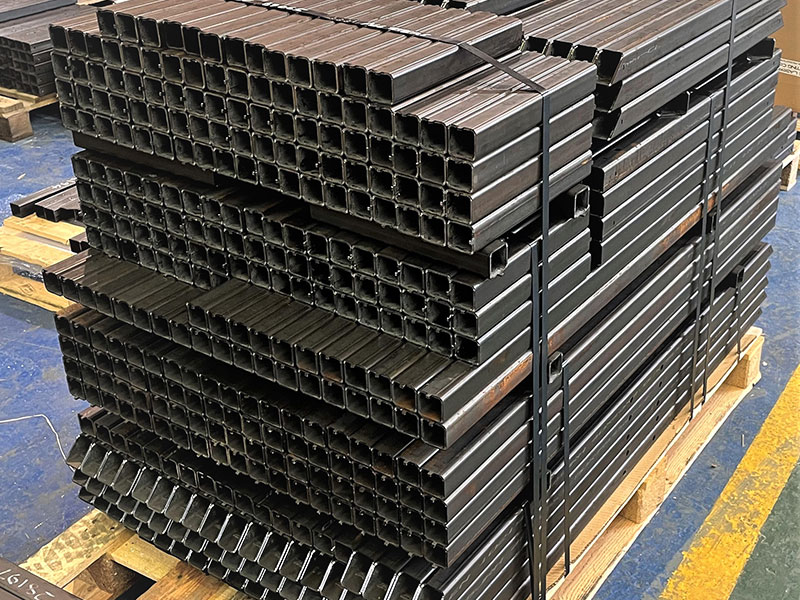

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

Self-jigging parts

Fabrication time and cost reduced by 50%

50% reduction of post processing operations

Increased throughput

Faster fabrication and assembly

Efficiency Through Design

Self-jigging parts

Fabrication time and cost reduced by 50%

50% reduction of post processing operations

Faster fabrication and assembly

Efficiency Through Design

Increased throughput

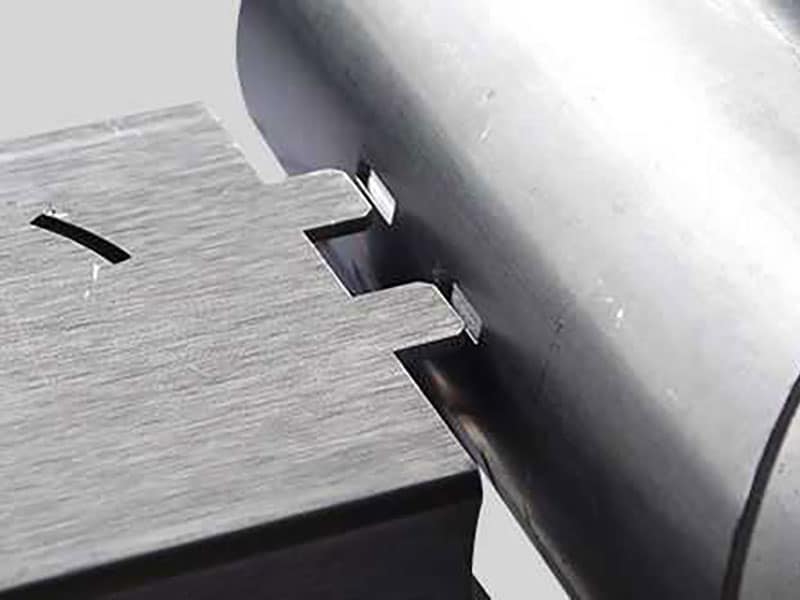

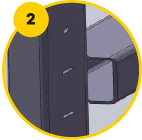

Self-Jigging Parts

Self-Jigging Parts

Fast and intuitive to assemble, accurate self-jigging parts reduce the margin for error. Known as self-locating, rationalised part design also reduces set up costs, eliminating the need for additional fixtures to assist with assembly.

Fast and intuitive to assemble, accurate self-jigging parts reduce the margin for error. Known as self-locating, rationalised part design also reduces set up costs, eliminating the need for additional fixtures to assist with assembly.

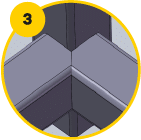

Part Folds

Design for manufacture can reduce multiple parts into a single-piece design. Part folds significantly reduce weld requirements, reduce material waste, and speed up assembly.

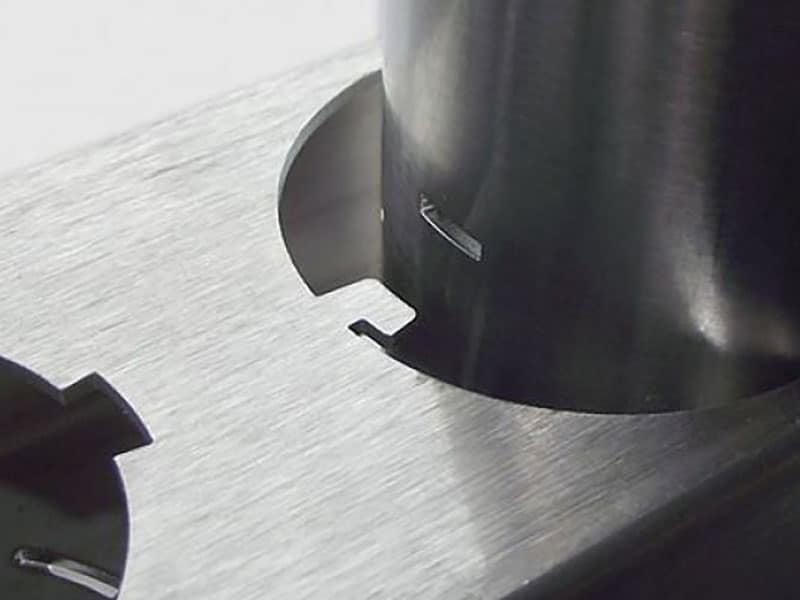

Slot and Tag

Slot and tag is used to circumvent the need to produce fixturing in order to hold two parts together. Slot and tag is a recent design feature now widely used for super-efficient welding and assembly processes.

Leading Design for Manufacture

Profitability is at the heart of Smart Design Production. When around 70% of product manufacturing costs originate from early design decisions, such as materials and machine routing, design for manufacturing has the potential to unlock the greatest margin boost.

Parts rationalised through The Laser Cutting Co’s CAD design service will have lower production costs but higher production rates. The development process tends to be shorter with fewer parts, thus delivering faster time to market.

Simplified parts that are easier to assemble massively reduces the margin for error, helping to protect margin and reputation. Fewer parts also reduces the volume of materials to be handled and stored, further reducing risk for the manufacturer.

How it Works

Simply send us your drawing, volumes and assembly capabilities. The Laser Cutting Co. in-house design team will reduce fabrication time and costs through rationalised part design.

Replace several manufacturing steps with one simple process using self-jigging parts:

- Remove margin for error

- Eliminate customer rejects

- Less handling and storage

- 50% cut in production time

- Increase product margins

- Double throughout

- Reduce time to market

- Faster assembly times

The Laser Cutting Co.’s Quality Promise

The highest possible quality standards with the after sales support to match

Our Factory Production Controls are in accordance with legally enforceable construction product regulation BS EN 1090 – Level 3, allowing intricate cutting of construction regulation profiles

Certified to BS EN ISO 9001:2015 for all profiling requirements

Quality Assurance

What sets The Laser Cutting Co. apart from our competitors

State-Of-The-Art Facilities

We continually invest in the latest laser cutting technology to provide the highest quality cut parts.

Nationwide Delivery

We can arrange local and nationwide deliveries and call-offs, so your items arrive when and where you need them.

24/7 Production

“Lights out” production enables cost effective production and impressive lead times.