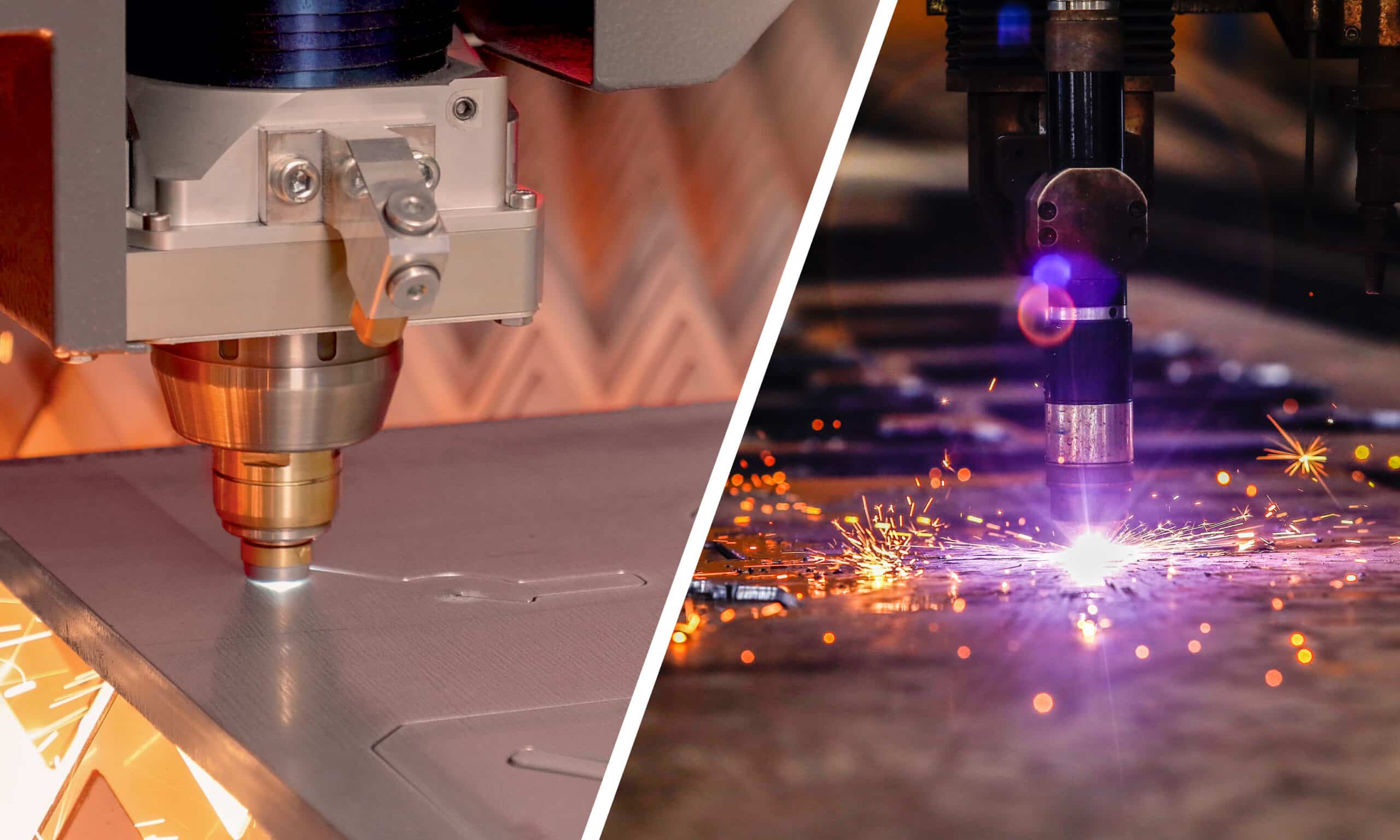

At The Laser Cutting Co., we’ve been harnessing the power of laser technology since 1981 to provide top-tier metal profiling and laser cutting services. Utilising our suite of laser cutting machines and state-of-the-art Trulaser Tube 7000 Fibre Machine, our high-capacity facility in Sheffield is a testament to the efficiency and quality this technology offers. But what makes fibre laser cutting machines so special, and how do they work?

How Does a Fibre Laser Cutting Machine Work?

Fibre laser cutting machines work by using a laser beam generated from a solid medium, typically a doped fibre, to cut through various materials. The process involves several key components and steps:

Laser Generation:

In a fibre laser, the source of the laser light is an optical fibre doped with a rare-earth element. The fibre is ‘doped’ to enhance its ability to generate laser light.

Laser Pumping:

The doped fibre is excited using diode lasers. This process is called pumping, where the energy from the diode lasers is absorbed by the doped fibre, causing the electrons in the fibre to rise to a higher energy state.

Laser Emission:

As the electrons return to their normal state, they release photons. These photons stimulate other excited electrons to release more photons, creating a chain reaction that generates a powerful and highly focused beam of light – the laser.

Beam Delivery:

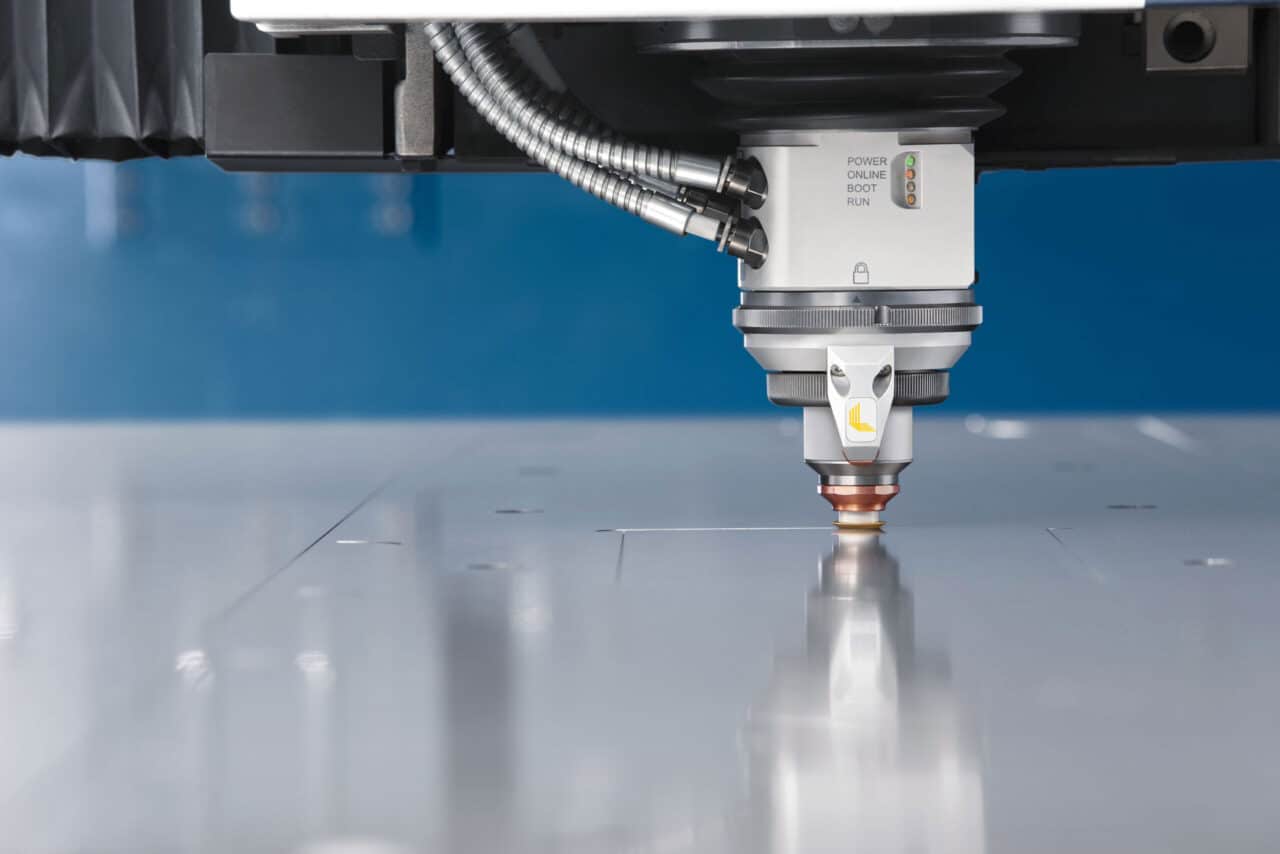

The generated laser beam is then delivered to the cutting head of the machine through a flexible fibre optic cable. This flexibility allows for easier manipulation and control of the laser beam, making fibre laser systems more versatile compared to other types of laser cutting machines.

Focusing the Laser:

In the cutting head, the laser beam is focused onto the material’s surface using a special lens or a curved mirror. The focus point of the laser is extremely small and precise, allowing for high-precision cutting.

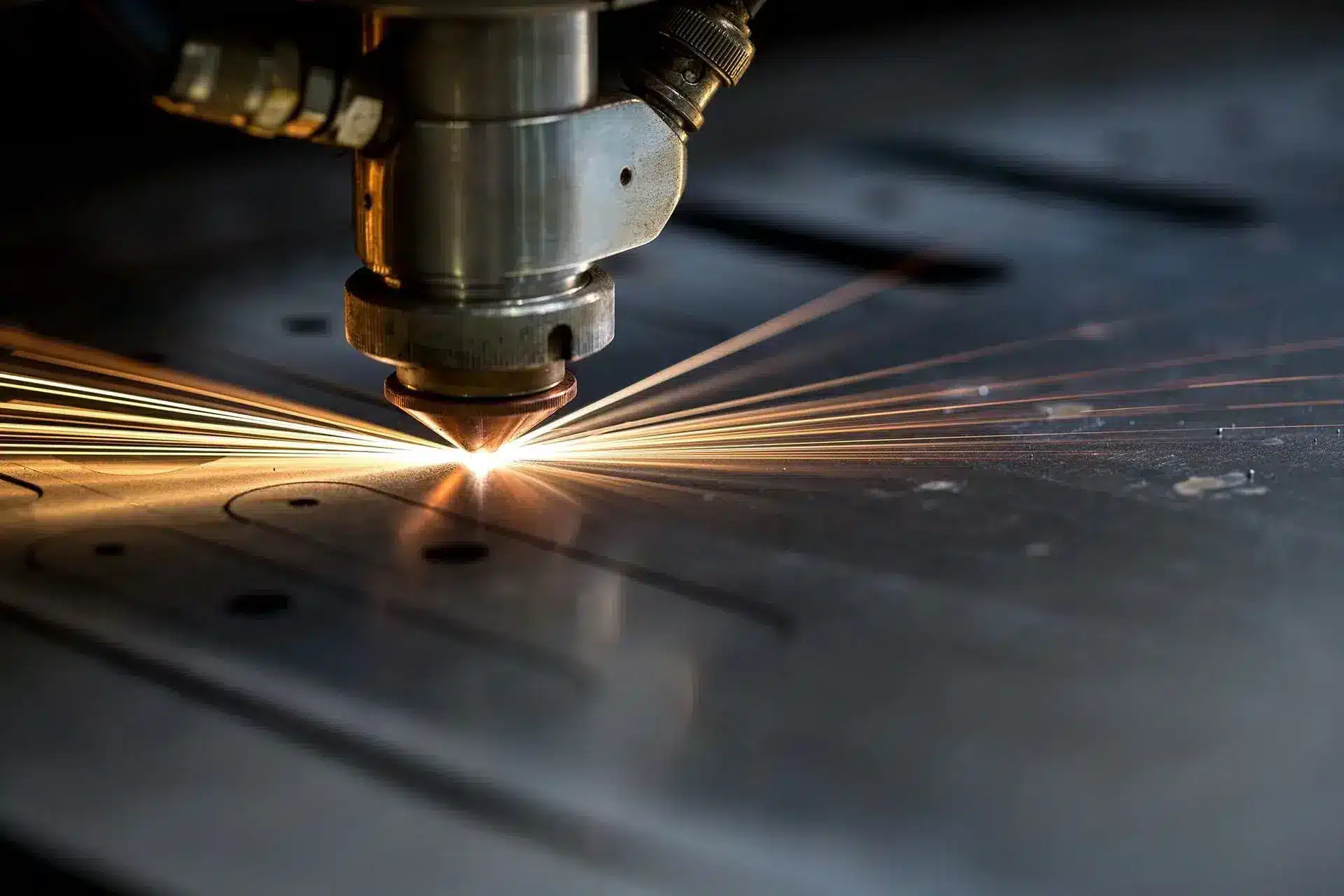

Cutting Process:

When the focused laser beam hits the material, it rapidly heats, melts, and vaporises the material. In some cases, a high-pressure gas, like oxygen, nitrogen, or air, is used to blow the molten material out of the cut, creating a clean edge.

Motion Control System:

The cutting head is moved over the material using a motion control system, which precisely guides the laser according to computer numerical control (CNC). This system allows the machine to cut complex shapes and patterns.

Cooling System:

Since the process generates heat, a cooling system is also necessary to maintain the temperature of the laser source and other components.

Software Integration:

The entire operation is controlled by specialised software, which allows for design input, path programming, and control over the cutting parameters.

Advantages of Fibre Laser Cutting

Fibre laser cutting offers several advantages over other cutting technologies:

High Precision and Accuracy:

Fibre lasers can produce extremely precise cuts with excellent edge quality and can maintain accuracy even when cutting complex shapes or intricate patterns.

High Speed:

Fibre lasers cut faster than traditional CO2 lasers, especially for thin materials. This increased speed translates into higher productivity and faster turnaround times for projects.

Energy Efficiency:

Fibre laser cutters are more energy-efficient compared to other types of lasers, like CO2 lasers. They convert a higher percentage of power into the laser beam, resulting in lower energy consumption and reduced operational costs.

Versatility:

They can cut a wide range of materials, including metals, plastics, and composites. This versatility makes them suitable for various industries, from automotive to electronics.

Minimal Heat Affected Zone (HAZ):

Fibre lasers produce a very narrow heat-affected zone, which minimises the thermal distortion of the cut material. This is particularly beneficial when working with metals, as it reduces the need for post-processing.

Reduced Waste:

The precision and efficiency of fibre lasers result in less material waste, which is beneficial from both an economic and environmental standpoint.

CNC Fibre Laser Cutting at The Laser Cutting Co.

Fibre Laser Cutting machines can deliver high-quality, precise cuts at rapid speeds making them indispensable in today’s manufacturing landscape. As technology continues to evolve, we here at The Laser Cutting Co. offer some of the best in precise metal fabrication utilising our suite of laser cutting machines and Trulaser Tube 7000 Fibre Machine.