Key Takeaways

- Structural sections are important for many heavy use needs, providing great strength, stability, and flexibility.

- Cutting techniques, such as large and open section cutting, allow for greater accuracy, reduced waste, and high efficiency when working with structural steel.

Structural steel is an important part of construction, which is frequently used in infrastructure and heavy manufacturing. Structural segments are most often seen in constructing bridges, buildings, structural components, or complex machinery, and are greatly desired for its great strength and support. However, there are many types of structural components on the market, and understanding each of them and their purpose is helpful in knowing which is the right type for your project.

The Different Types of Structural Sections

There are several types of structural sections that are used in heavy sectors to meet specific design and weight requirements. The most common types include:

Channels

Shaped like the letter ‘C’, these hot-rolled steel beams are frequently used in construction as a lightweight yet durable metal. A PFC channel is a beam with two parallel flanges connected by a web, which gives the channel its name. This type of section is often used as floor joists, framing, or as additional strength support without adding extra weight.

RSA Angle

Angle steel, also referred to as L-section steel, is available in two variations. This includes RSA-e, which is when both legs of the component are of equal length, and is often used where there is a symmetrical load requirement. RSA-u, on the other hand, is when the legs are of different lengths and constrained space or varied loads can apply. These sections are mostly used as braces, frames, supports, and reinforcements.

Tubes

Hollow structural sections are available in various configurations, depending on a project’s required needs, and offer an amazing strength-to-weight ratio. These are uniform and versatile parts, available as either square, rectangular, or circular hollow sections. This makes them especially great for various uses, such as in construction, architecture, and mechanical purposes. Their closed shape results in them having great resistance to distortion, so they’re most suited for projects that need stability.

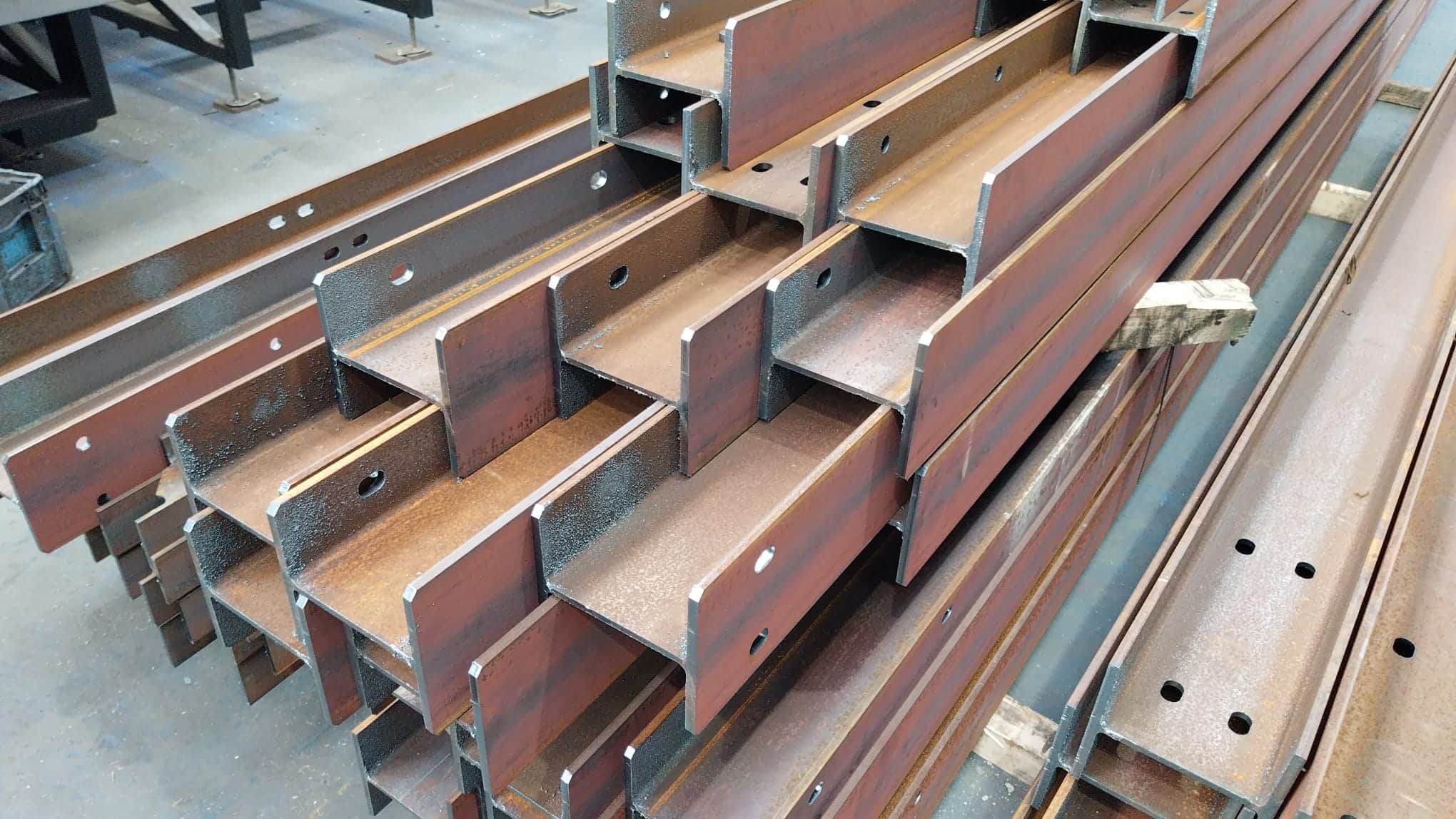

Beams

Beams provide excellent structural support and are most commonly named as a universal beam, which encompasses ‘I’ or ‘H’ shapes. These types of shapes have a flange that extends from a central web, offering support in buildings and bridges. I-beams have a slightly tapered flange, whereas H-beams are parallel and provide greater load capacity.

Columns

A universal column, much like beams, can also be called an ‘I’ or ‘H’ shape, but are designed for vertical load bearing. A universal beam is typically equal in length to its height, and is often used as a structural framework, lintel, or in mezzanine floors.

The Cutting Processes for Structural Sections

Choosing the right cutting method, along with your structural section, is also just as important. Each process offers different advantages and finishes, depending on project requirements.

Mechanical Cutting

This traditional method includes manual sawing, drilling, and milling techniques. These processes still hold a place today, but they are much more suited for straight cuts and basic profiles, especially on thicker materials. Mechanical cutting can often be slower, especially when dealing with complex shapes or higher volumes, and has a greater likelihood of needing additional finishes.

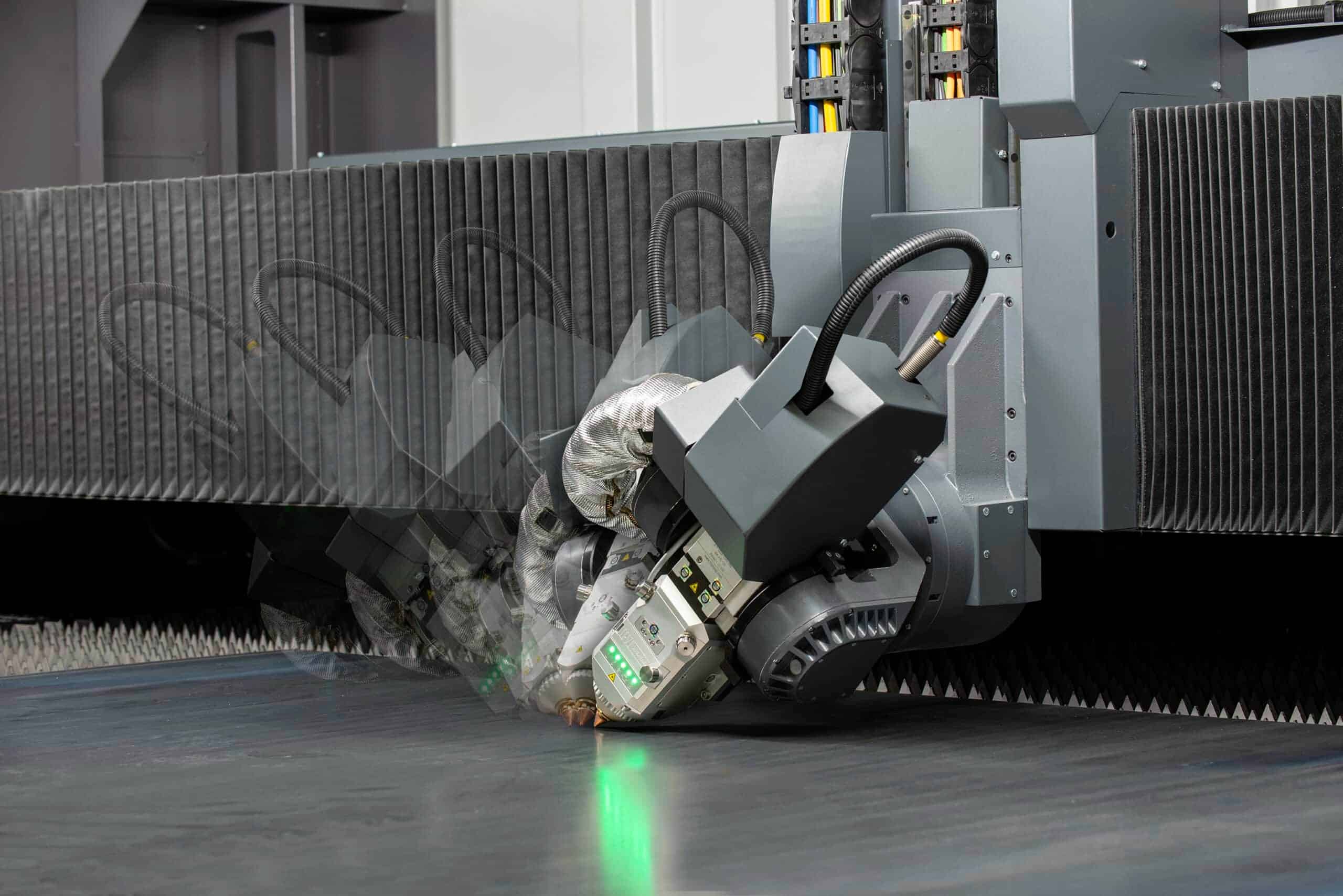

Laser Cutting

An incredibly popular cutting method, laser cutting provides high-accuracy, even on complex or delicate designs. Using a highly focused beam of light, laser cutting provides fast results with burr-free edges and minimal heat distortion. Large and open section cutting is particularly suited for structural sections, delivering 60° bevel contours, large sections, reducing weld preps, and high efficiency, minimising the need for secondary processes.

Plasma Cutting

Plasma cutting uses a high-temperature plasma arc that cuts through conductive materials. This method is mostly used for thicker structural steel and provides exceptionally fast cutting speeds. Plasma is very cost-effective for heavy-duty applications, although it may produce a wider kerf, so it might require additional finishes, depending on the final outcome.

Waterjet Cutting

This cutting type uses a high-powered stream of water, often mixed with an aggregate, which cuts through materials without using heat. This is generally a slightly slower process, but it is excellent on thicker materials that may otherwise be sensitive to heat distortion. Waterjet cutting also provides high-quality edges with great accuracy, even across higher volumes.

Achieve High-Quality Profiling for Structural Sections

Selecting the right partnership between project outcome, structural section, and cutting process can be difficult, which is why The Laser Cutting Co. are on hand to guide you through the journey. We deliver a range of services, offering a full turnkey approach for projects that require structural sections.

We collaborate and partner with our customers to fully understand your needs across the journey, providing full transparency throughout. For tailored, quality laser cutting solutions and guidance, get in touch with a member of our expert team today.