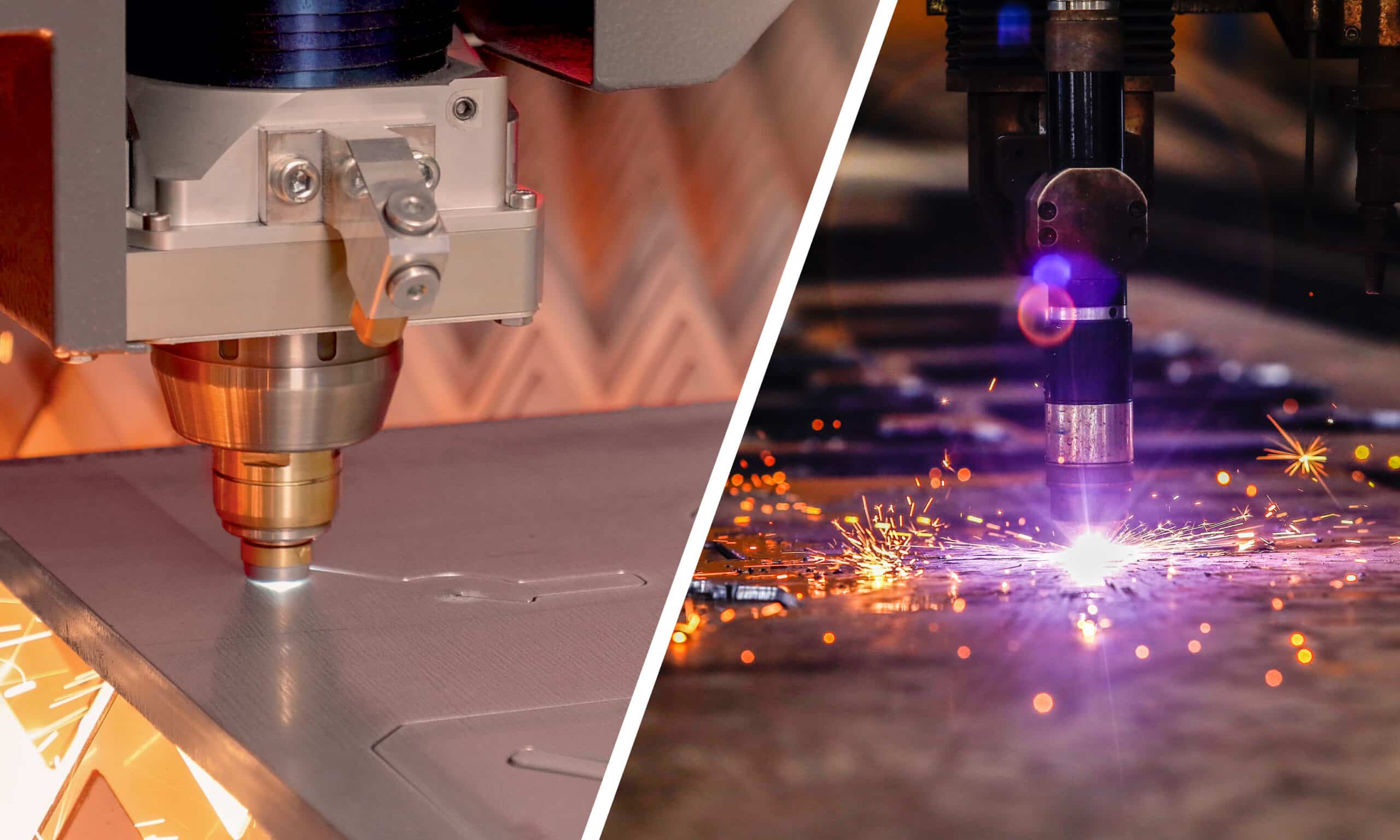

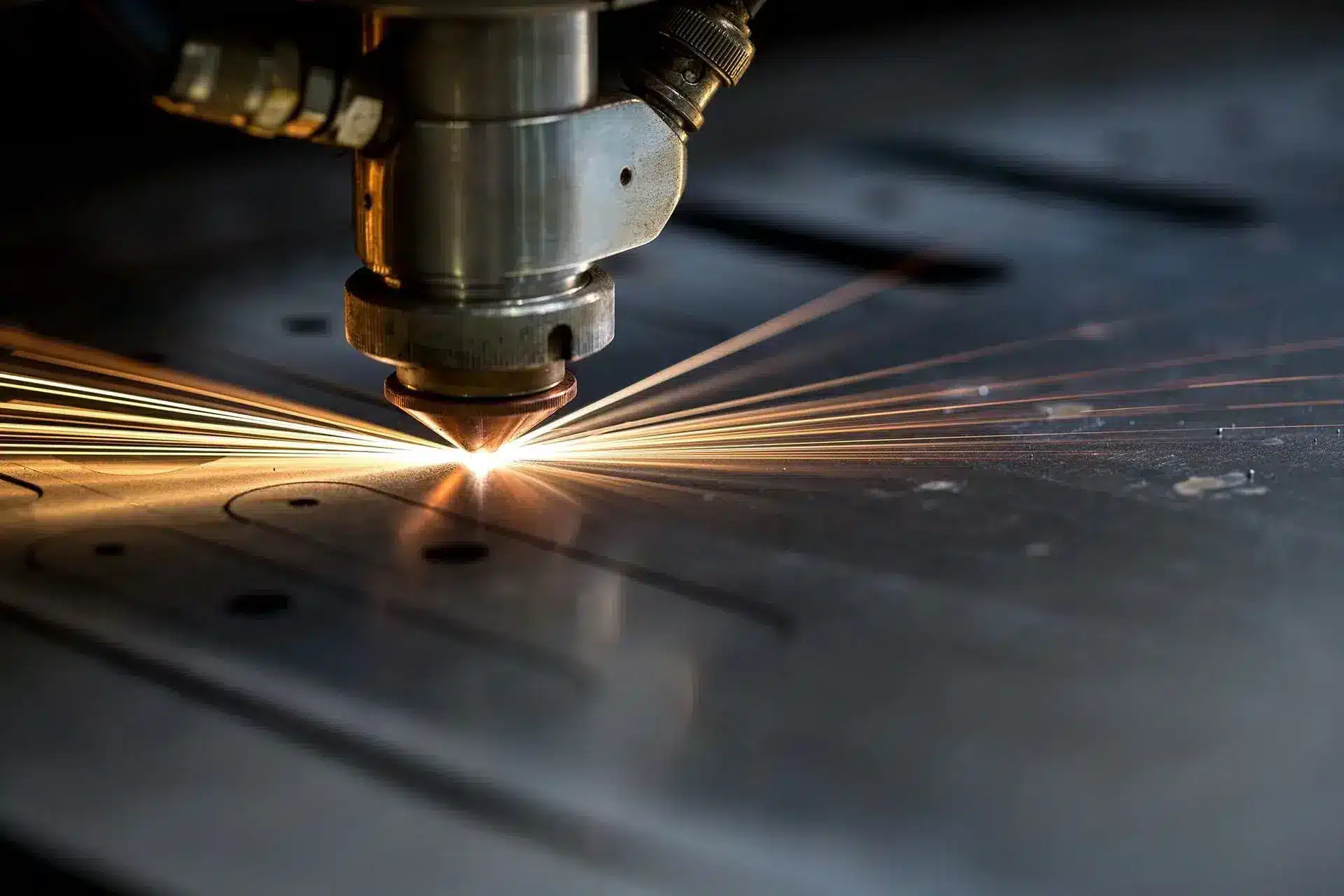

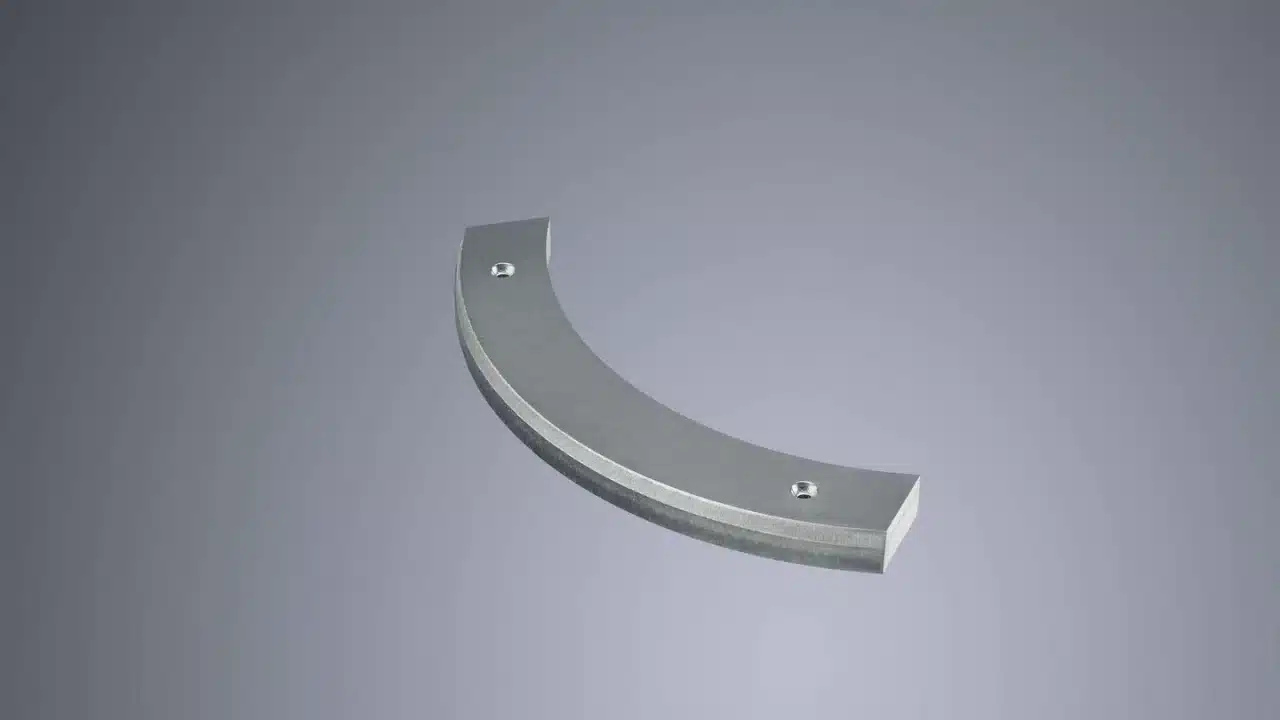

Automated weld edge preparation is here. This new laser cutting technology is now available in the UK and delivering impressive results. Once only available through investment in complex machinery and a special 3D cutting head, laser bevel cutting can now automatically apply 45° chamfers on both inside and outside contours during profiling. Using the modern standard of laser cutting machine, laser profiling services can produce bevelled edges and countersinks of the highest quality, in seconds.

The new technology has the potential to deliver significant cost savings for companies in the sheet metal cutting industry. Any manufacturer using joining processes or screw connections can benefit from laser bevel cutting. As a value-added service from laser cutting companies, customers can take delivery of their order, cut to size with absolute accuracy, and complete with superior quality countersinks and weld preps.

Manual weld preparation is resource hungry, consuming man and machine hours. Laser bevel cutting is a fast way to free time on milling and grinding machines and boost productivity. Engineers spending hours preparing awkward-to-reach inner contours can put their skills to better use. The advent of bevel laser cutting is unique to sheet metal processing. Manufacturers can now order in parts, with weld seams fully prepared, ready for assembly.

Laser cutting is well-known for producing fine contours with tighter nesting for total efficiency. With the addition of EdgeLine bevel technology, laser cutting is now also known for delivering unrivalled weld seam quality. Laser cutting companies can handle sheet metal sizes up to 2000 x 4000mm and up to 50mm thick. Automated bevel and countersinks are available up to 30mm thick, supporting the majority of profiling jobs.

Laser cutting service providers investing in this state-of-the-art of technology can provide a complete, one-stop metal profiling shop. Customers in the sheet metal industry can derive a series of benefits, from outsourced metal profiling:

- Aggregated buying prices

- Design service for downstream efficiency

- Laser cutting

- 45° bevels on inner and outer contours

- Countersinks of any size

- FlowDrill and tapping

- Profile bending.

Outsourcing metal profiling means your supplier invests in the latest technology, so you don’t have to. Send your drawing over to your laser cutting supplier and they will do the rest.

The Laser Cutting Co. offer a complete metal profiling service with rapid turnaround times, thanks to 24-hour, lights-out production and a suite of 10 laser cutting machines. Located in Sheffield, South Yorkshire, an extended range of services are available via a network of trusted local suppliers, such as galvanising, with the same one-stop service.

Get a no obligation quote for you next project. See how much you could save when you opt for a quality laser cutting service.