Laser Cutting Applications for Laser Cut Tubes

Here at The Laser Cutting Co., we understand more than most that in today’s advanced manufacturing landscape, precision is paramount. Industries ranging from automotive and agricultural machinery to mechanical apparatus and architecture, demand high-quality components that meet stringent specifications, which is why we endeavour to provide high-quality solutions to suit a plethora of laser cutting applications.

Among the cutting-edge technologies revolutionising manufacturing processes, laser cutting has emerged as a versatile and efficient solution. In particular, laser cut tubes have garnered significant attention due to their exceptional precision, versatility, and widespread applications.

Advantages of Laser Cut Tubes:

Precision:

Laser tube cutting provides unmatched precision, enabling the production of complex shapes, intricate patterns, and tight tolerances. This accuracy is crucial for industries such as automotive, where even the smallest deviation can impact performance and safety.

Versatility:

Laser cutting technology can be applied to a variety of tube materials, including stainless steel, aluminium, and titanium. This versatility allows manufacturers to cater to the specific needs of diverse industries, creating tailor-made solutions.

Speed and Efficiency:

Laser cutting is a fast and highly efficient process, ensuring rapid production and reduced lead times. The automated nature of laser cutting machines allows for high-volume production, making them ideal for industries with large-scale manufacturing requirements.

Cost-effectiveness:

While laser cutting equipment may require an initial investment, the long-term cost benefits are significant, and The Laser Cutting Co. invests in the best so you don’t have to; mitigating your costs, and improving profit. The precision and efficiency of laser cut tubes result in minimal material wastage, a reduction in overall production costs, and an increase in profitability.

Laser Cut Tubes Applications

Automotive Industry:

Tube laser cutting finds extensive use in the automotive sector for applications such as exhaust systems, roll cages, and structural components. The precision of laser cutting ensures tight fitment and optimal performance, while the durability of the materials used guarantees longevity and safety.

Furniture:

Laser cut tubes are finding increased use in the furniture industry, offering designers and manufacturers a wide range of creative possibilities. Whether it’s modern and sleek metal frames for chairs and tables or intricate decorative elements, tube laser cutting allows for precise and aesthetically pleasing designs. The ability to cut through various materials with precision enables the creation of customised furniture pieces that meet the demands of both residential and commercial spaces.

Shop Fitting/Units:

The retail sector relies on attractive and functional shop fittings and displays to showcase products effectively, and laser cutting is instrumental in creating structures with precision and durability. From clothing racks and shelving units to signage and branding elements, tube laser cut parts offer versatility in design while maintaining structural integrity. Retailers can benefit from the aesthetic appeal, customisability, and cost-effectiveness.

Agricultural Machinery:

The agricultural industry often requires robust machinery and equipment that can withstand demanding conditions, and play a vital role in the manufacturing of components such as frames, brackets, and supports for agricultural machinery. The precision and strength of laser cut tubes ensure the durability and reliability of these critical agricultural tools, contributing to increased efficiency and productivity in farming operations.

Fitness Equipment:

Fitness enthusiasts worldwide rely on durable and safe exercise equipment. Laser cut tubes are extensively used in the production of fitness equipment such as weight machines, gym racks, and exercise frames. The precise cuts and high-quality materials provided by laser cutting ensure the structural integrity and safety of these fitness products, enabling users to work out with confidence.

Mechanical & Apparatus Engineering

In the field of mechanical and apparatus engineering, laser cut tubes serve as fundamental building blocks for a wide range of applications. From conveyor systems and material handling equipment to industrial machinery and automation systems, tube laser cutting provides the necessary components for these complex engineering solutions. The precision and reliability ensure seamless integration and smooth operation in mechanical and apparatus engineering projects.

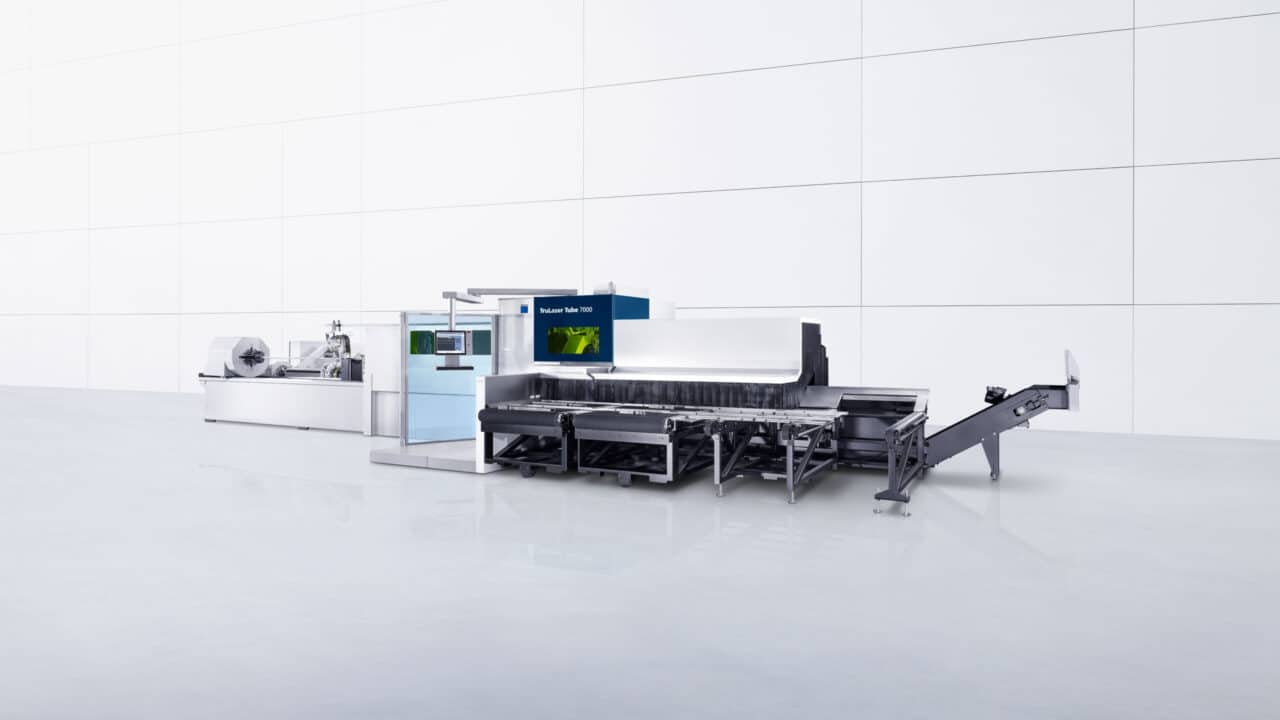

Improving Precision – Our New Trulaser Tube 7000 Fibre Machine

Laser cut tubes have revolutionised manufacturing processes across a multitude of industries. Their exceptional precision, versatility, and efficiency make them indispensable for producing high-quality components. At The Laser Cutting Co., we recognise that as technology continues to advance, laser cutting techniques are likely to become even more refined, offering increased capabilities and opening new avenues for innovation.

Our ethos for continuous self-improvement is at the forefront of all of our practices, and our latest investment, the Trulaser Tube 700 Fibre Machine, exemplifies this. Featuring a TruDisk solid-state laser and RapidCut, the high feed rates of the laser are able to handle even the most complex and minute of contours, and maximise our already impeccable quality, lead-times, and productivity; producing industry-defining tube laser cutting services for a variety of laser cutting applications.