Here at The Laser Cutting Co., our sub-contract manufacturing and fabrication services offer unparalleled precision and efficiency. Established in 1981 with a wealth of knowledge and experience, we understand more than most that identifying the right metal profiling provider plays a pivotal role in determining the overall success and longevity of your projects.

As a leading provider of an extensive range of metal profiling services, we can recognise the important factors that should be considered when choosing a material profiling supplier. Whether you need bevel and countersink services, flow drilling, smart design production, sheet metal bending, or any other specialised services, selecting the right provider involves considering these critical factors.

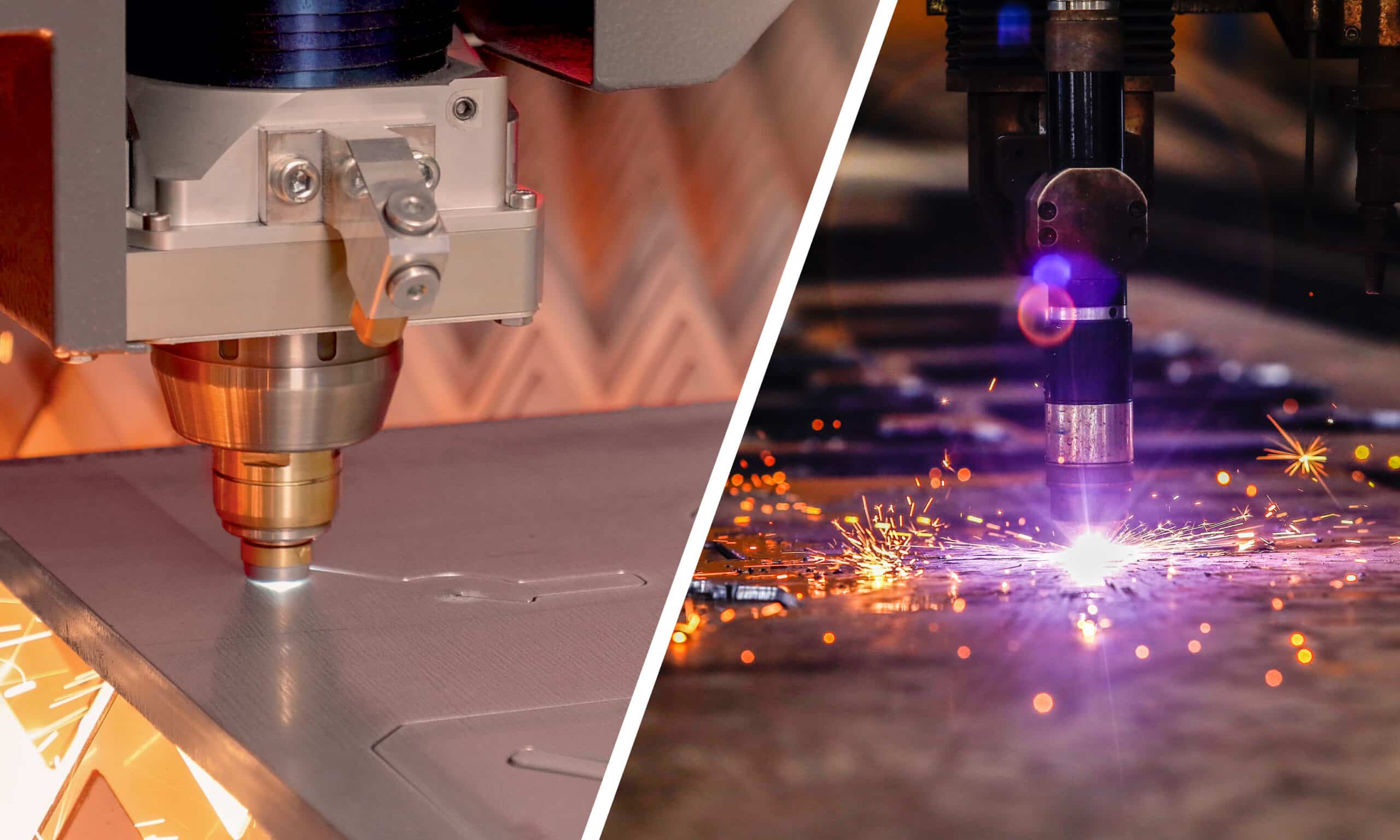

Automation and Technological Capabilities

Committed to consistent re-investment, The Laser Cutting Co. is proud to house a plethora of in-house metal profiling services; embracing automation and utilising the most cutting-edge technologies to enhance your downstream efficiencies. By offering automated processes such as laser cutting for bevels and countersinks, we ensure accuracy and efficiency; eliminating the margin for human error.

Materials and Thickness Range

Another factor to consider when determining the right metal profiling service for your project is the range of materials that you will be working with, and the required thickness of those materials, as some profiling technologies will be more suitable than others. Providing a versatile service, The Laser Cutting Co. is capable of processing a variety of materials at various thicknesses, including mild steel, stainless steel, copper, brass, bronze, and aluminium; providing flexibility for diverse projects.

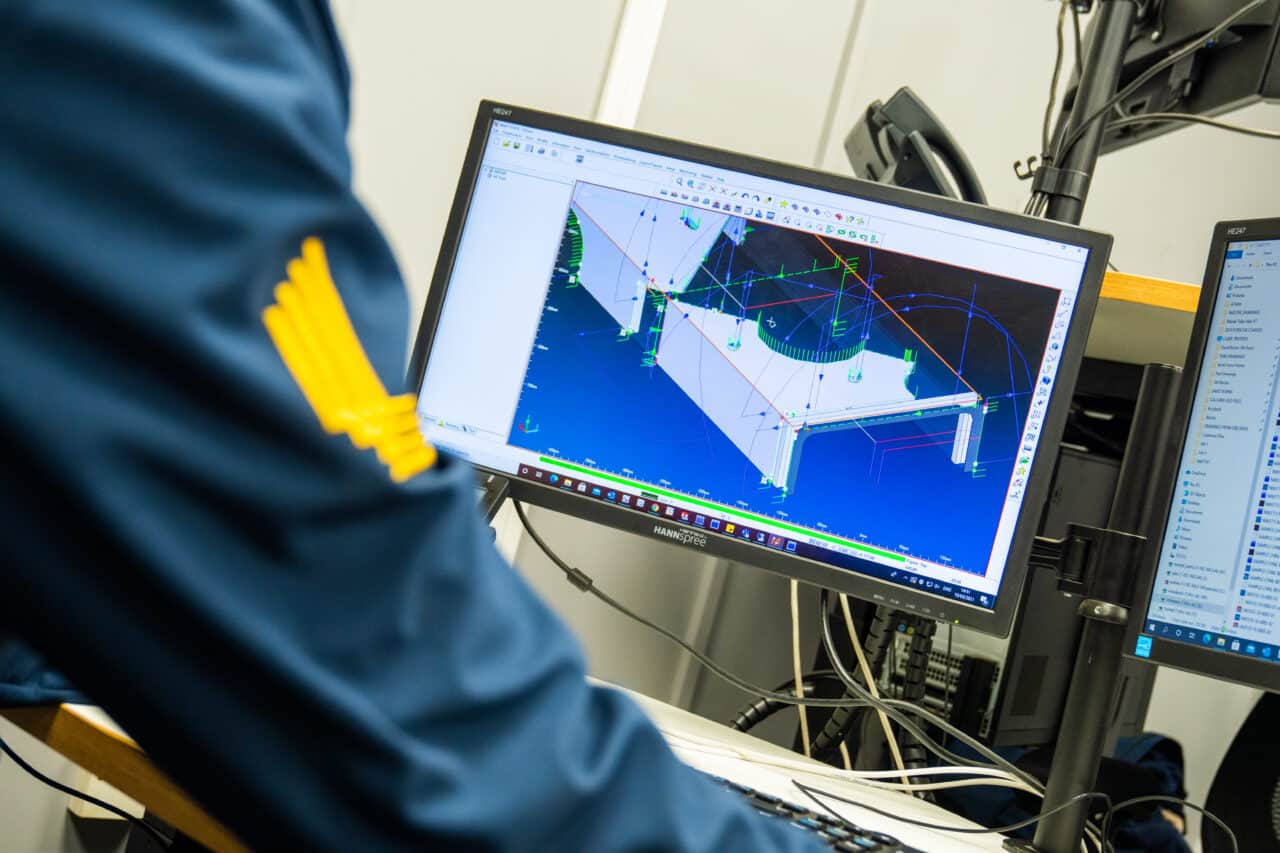

Smart Design and CAD Capabilities

At the forefront of innovation, one of our many metal profiling services includes our state-of-the-art Smart Design Production. If a factor you’re looking for is to enhance your downstream efficiencies, then Smart Design Production is a material profiling service which can encompass all of your requirements. Involving a holistic approach to part optimisation using Computer-Aided Design (CAD), the ability to reduce component volume, material waste, and overall complexity through smart design can lead to substantial cost savings.

Quality Certifications

To ensure that your material profiling is processed safely, efficiently, and correctly, it’s important to check that relevant quality certifications are in place. ISO9001 and other industry-specific accreditations indicate a commitment to maintaining high standards in the production process. This is crucial, especially for industries where precision and reliability are non-negotiable. The Laser Cutting Co. is proud to be accredited for both BS EN ISO 9001:2015 for all profiling requirements and S EN 1090 Level 3 for intricate cutting of construction regulation profiles.

Our Range of Services

Here at The Laser Cutting Co., we consider services beyond basic cutting, such as flow drilling, sheet metal bending, tube laser cutting, and other additional profiling services to add efficiency to your downstream processes. Our one-stop profiling shop provides added convenience, and our comprehensive range of metal profiling services allows you to streamline your workflow, as well as benefit from cost savings.

Experience and Reputation

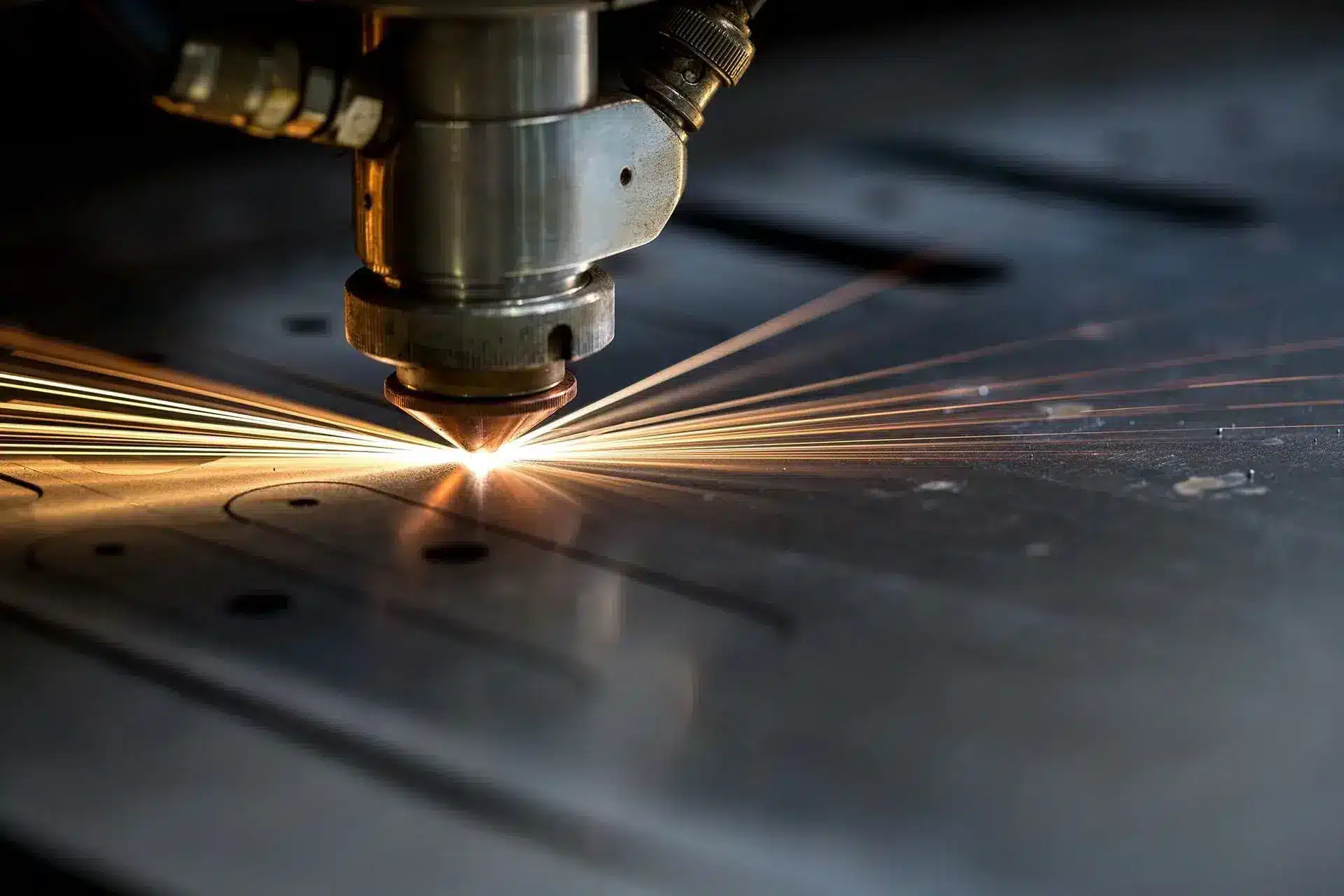

An important factor to consider when selecting the right metal profiling service is the service provider’s experience and reputation. With over 40 years of laser profiling experience, and an ethos for continuous self-improvement, The Laser Cutting Co. demonstrates a deep understanding of the industry; constantly re-investing into our profiling technologies for the benefit of our clients and their projects.

Efficiency and Turnaround Time

Efficiency and time constraints are incredibly important factors to consider when exploring different metal profiling service providers, and the efficiency of the service in terms of production time and turnaround should be assessed. To ensure unrivalled efficiencies and project turnarounds, The Laser Cutting Co. operates 24/7 and offers “lights-out” production to provide rapid lead times; enabling you to meet tight deadlines and project schedules.

Flexibility and Customisation

A reputable metal profiling service provider should strive to be flexible to its clients and capable of offering customisation when necessary. The ability to accommodate both small and large volume profiling jobs, handle various materials, offer nationwide delivery, and provide tailored solutions based on project requirements is a key factor in the decision-making process and one which The Laser Cutting Co. has worked tirelessly to perfect over our many years of operation.

Choose The Laser Cutting Co. For Fully Comprehensive Metal Profiling Services

Choosing the right metal profiling service involves a careful consideration of these factors to align the service provider with your project needs and quality expectations. As a leading metal profiling provider, The Laser Cutting Co. takes immense pride in the quality services we have endeavoured to perfect over our 40-year legacy and is ardent in our commitment to consistent self-improvement and innovation; investing in the latest, most advanced and reliable material profiling technologies so that you don’t have to.