What is Structural Steel Fabrication?

Here at The Laser Cutting Co., we are committed to continuously improving the quality of our services and always go above and beyond to develop

Here at The Laser Cutting Co., we are committed to continuously improving the quality of our services and always go above and beyond to develop

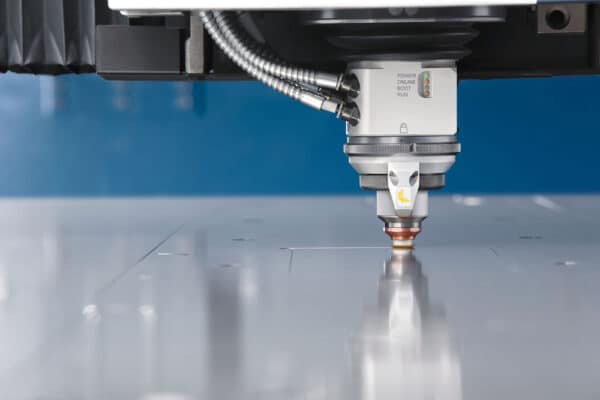

When it comes to quality assurance, we here at Laser Cutting Co continually invest into the very latest and most advanced laser cutting technology, which

Friction drilling is a technique used in manufacturing to apply precise fastening points in metals. The process is often used during metal profiling process, such

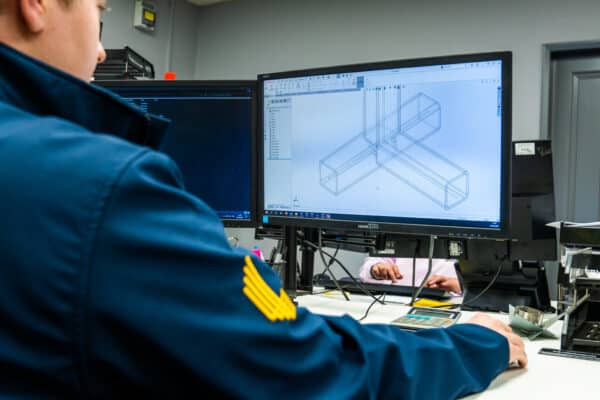

Every design choice has consequences down the line. Positive or negative, it’s important to understand the impact of every decision, from choice of material to

When it comes to waterjet profiling, it’s easier to ask what this versatile cutting technology cannot cut. Waterjet is commonly used to cut metals, stone,

Outsourcing elements of manufacturing is widely accepted as a sound cost control method. For manufacturers, doing everything under one roof adds layers of complexity that

Automated weld edge preparation is here. This new laser cutting technology is now available in the UK and delivering impressive results. Once only available through

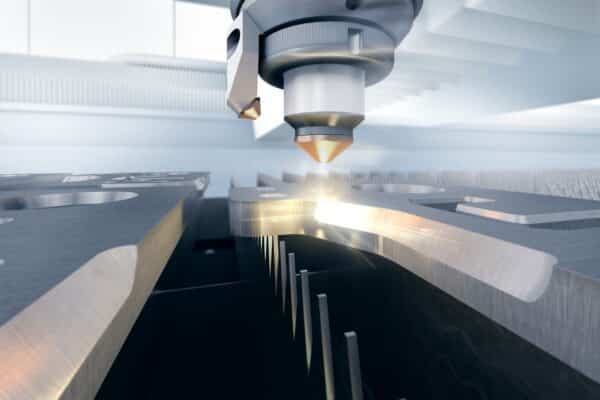

In metal fabrication, precision is paramount. While there is more than one way to skin a cat, the need to produce ever more complex cuts,

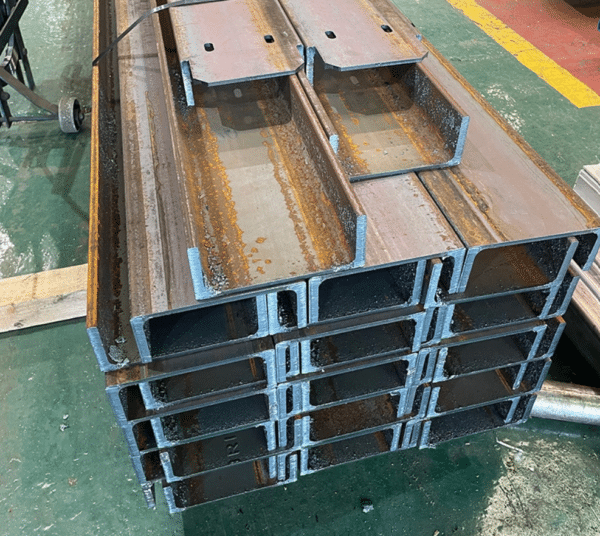

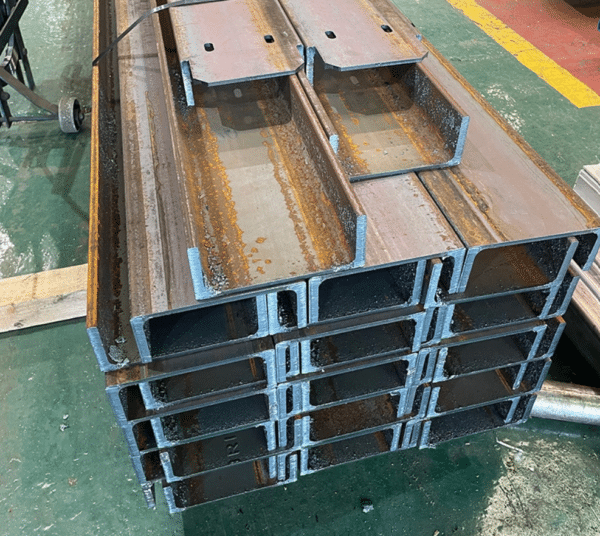

Tubes and profiles are everywhere. From vehicles and machines to furniture and buildings, there can be a multitude of tubes and profiles contained within a

The current situation in Ukraine is having a direct impact on the European steel market for a number of reasons. As such we see it

A normal article regarding a new laser installation in the current market climate would read along the lines of “during these unprecedented times innovation is

During these unprecedented times we are proud to reassure customers that we are open for business and fully operational having gained Key Supplier status subject

We continually invest in the latest laser cutting technology to provide the highest quality cut parts.

We can arrange local and nationwide deliveries and call-offs, so your items arrive when and where you need them.

“Lights out” production enables cost effective production and impressive lead times.

State of the art facilities combined with the latest laser cutting technology and a determination to succeed enable us to give our customers a highly competitive advantage.

The Laser Cutting Co. Ltd,

58 – 64 Catley Road,

Sheffield, S9 5JF

Phone: 0114 242 0101

Email: sales@lasercutting.co.uk

Website built by Fenti Marketing