Rebuilding a Porcshe 908

With a wealth of industry leading experience spanning a wide variety of sectors, some projects can be that much more satisfying. This particular project saw

With a wealth of industry leading experience spanning a wide variety of sectors, some projects can be that much more satisfying. This particular project saw

As the UK market changes ready for Brexit our competitors may be left with the option of only being able to UKCA mark your products

Use this link to find to our new brochure, showcasing our capabilities and machines in a bite-size, easy to read format! CLICK HERE FOR OUR

Laser Cutting Co is pleased to announce a major investment for automatic and continuous 3D laser cutting of long structural materials High-precision cutting of complex

Made In Sheffield is one of the world’s great brands, made famous internationally as a mark of origin and quality on the city’s manufactured products.

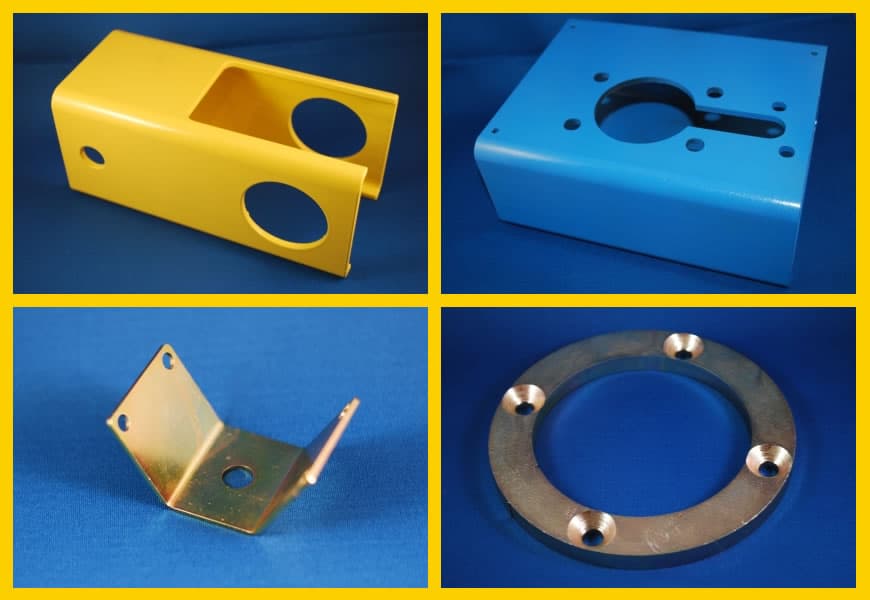

The Laser Cutting co is pleased to announce an enhanced range of added value processes that will be of significant value to our customer projects

We are looking for a customer focused sales estimator professional to join our team in Sheffield. The role will involve liaison and management of proposals

In recent years we have evolved our processes and operations across all aspects of our business. During the last few days we have passed our

We would like to take this opportunity to say a thank you to all of our staff, stakeholders, suppliers, partners and customers for your support

The Laser Cutting Co is pleased to announce an investment in Solid Works 3D CAD software for improved project simulation, product data management, mechanical design

The Laser Cutting Co has embarked on a major customer improvement process covering all aspects of our business in relation to servicing your requirements. From

A significant investment project has been implemented at The Laser cutting Co. over the last month with new Server technology and in excess of 15

We continually invest in the latest laser cutting technology to provide the highest quality cut parts.

We can arrange local and nationwide deliveries and call-offs, so your items arrive when and where you need them.

“Lights out” production enables cost effective production and impressive lead times.

State of the art facilities combined with the latest laser cutting technology and a determination to succeed enable us to give our customers a highly competitive advantage.

The Laser Cutting Co. Ltd,

58 – 64 Catley Road,

Sheffield, S9 5JF

Phone: 0114 242 0101

Email: sales@lasercutting.co.uk

Website built by Fenti Marketing